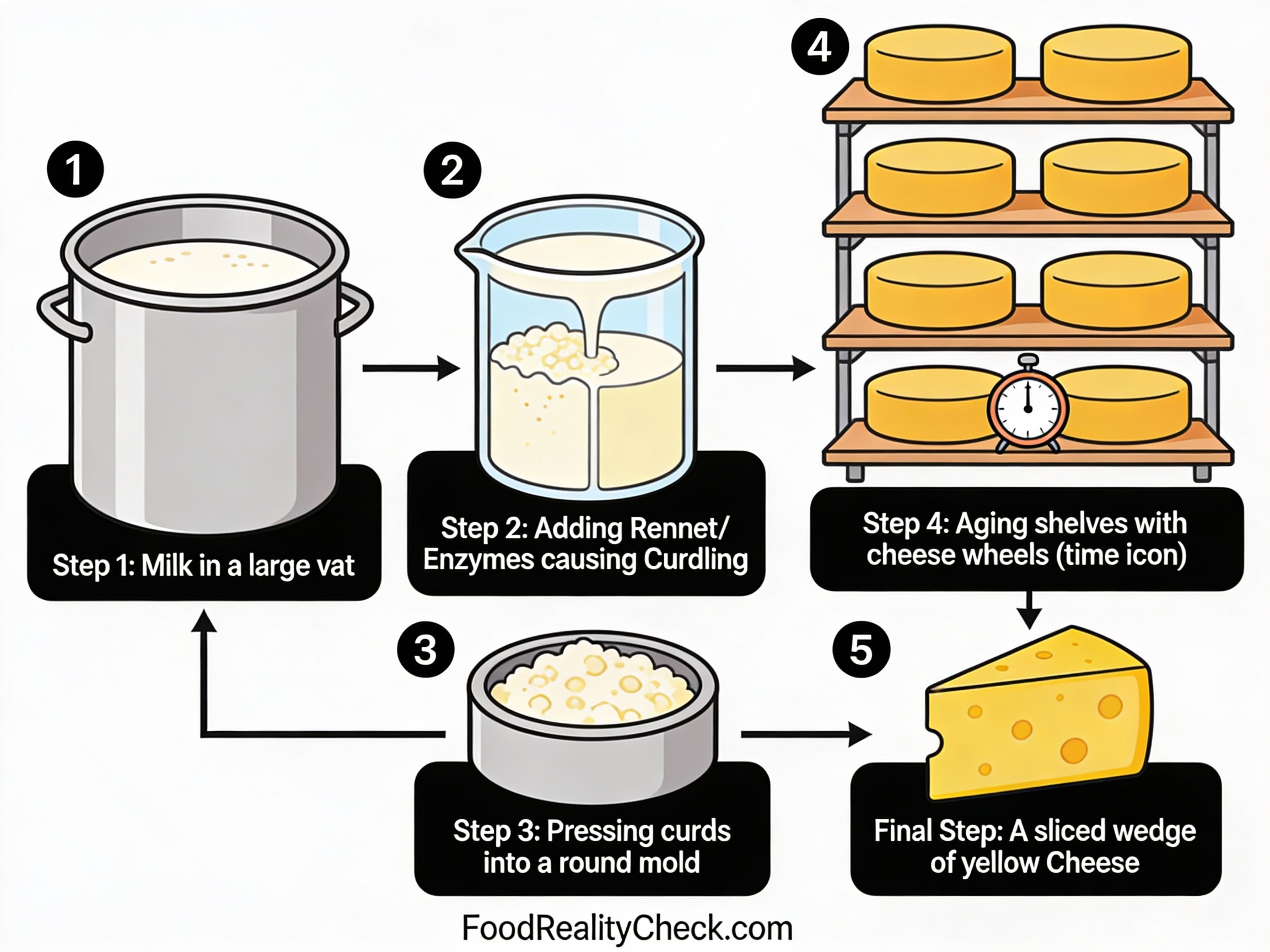

How is Cheese Made?

From milk to your plate.

The Overview

Most cheese comes from industrial dairy facilities, not artisans in caves.

The process transforms milk into solid curds through fermentation and bacterial cultures.

Here’s exactly what happens step by step.

🥘 Main Ingredients

• Milk (cow, goat, or sheep)

• Starter cultures (lactic acid bacteria)

• Rennet (coagulation enzyme)

• Salt

Step 1: Preparing the Milk

Fresh milk is pasteurized at 70-72°C for 15-20 seconds to kill harmful bacteria.

The milk is then cooled to the renneting temperature of about 30°C.

This takes about 20-30 minutes.

Step 2: Acidifying with Cultures

Lactic acid starter cultures are added to the milk to begin fermentation.

These beneficial bacteria convert milk sugars into lactic acid, lowering pH and developing flavor.

The milk ripens for 30 minutes to an hour at 25-40°C.

Step 3: Curdling with Rennet

Rennet—an enzyme containing chymosin—is added to coagulate the milk proteins (casein).

Milk proteins clump together, trapping fat and whey as a sponge-like curd.

This takes 30-40 minutes at optimal temperature.

Step 4: Cutting the Curd

Once curds form a solid mass, cheesemakers cut them into small grain-sized pieces using long curd knives.

Cutting releases whey, beginning the separation process.

Smaller cuts produce drier, harder cheese; larger cuts produce softer cheese.

Step 5: Cooking, Stirring & Draining

The curds are slowly heated to 30-50°C while stirring constantly.

Higher temperatures expel more whey, creating firmer cheese.

After cooking, liquid whey is drained away, leaving only curds.

Why This Process?

Modern cheese production uses these steps for consistent texture and shelf-life.

Temperature and pH control prevent bad bacteria growth and develop complex flavors.

And fermentation preserves milk naturally through lactic acid, keeping costs manageable.

What About Aging & Additives?

Most commercial cheeses include:

• Salt (0.5-2%) – for flavor and preservation

• Lipase enzymes – for tanginess and aroma in some varieties

• Calcium chloride – for improved curd formation

Cheese is then aged in controlled rooms at 12-15°C.

Aging times vary from weeks (soft cheese) to years (hard cheese).

The Bottom Line

Cheese production is a precise science combining fermentation, temperature control, and microbiology.

It’s designed for consistent quality and extended shelf-life.

Now you know exactly what happens from milk to mature cheese.