How Is Apple Juice Made?

From orchard-fresh apples to bottled juice through pressing, clarification, and pasteurization.

The Overview

Apple juice is produced by washing, crushing, and pressing fresh apples to extract liquid, then clarifying it to remove pulp and solids, pasteurizing it for safety, and bottling it for distribution.

The manufacturing process transforms whole apples into clear or cloudy juice through enzyme-assisted extraction, mechanical pressing, filtration, heat treatment, and precise packaging—all designed to preserve fresh apple flavor while ensuring food safety and shelf stability.

Here’s exactly what happens from harvested apples to the juice in your glass.

🥘 Main Ingredients & Materials

• Fresh apples (multiple varieties for flavor balance)

• Water (for washing and dilution)

• Pectinase enzyme (optional, for juice extraction efficiency)

• Natural or synthetic ascorbic acid (Vitamin C, preservative)

• No added sugar (unless specified for concentrate)

Step 1: Apple Harvesting & Transport

Apples are harvested from orchards during peak ripeness (typically September-November in northern hemisphere) and transported in bulk bins to juice processing facilities within 24-48 hours of harvest.

Rapid processing is critical—apples begin to degrade immediately after harvest, losing juice yield and developing off-flavors if stored too long.

Premium juice producers use fresh-harvested apples the same day they arrive, while budget producers may use apples stored for weeks or months in cold storage.

Step 2: Visual Inspection & Sorting

Apples pass through electronic optical sorters that scan each fruit for size, color, and defects like bruising, mold, rot, or insect damage.

Damaged apples are automatically rejected and diverted—they produce off-flavors, reduce juice quality, and pose food safety risks.

Quality apples continue to washing while damaged fruit is composted or used for animal feed.

Step 3: Washing & Surface Cleaning

Selected apples are conveyed through industrial washing machines where high-pressure water jets (1,500-3,000 PSI) spray them to remove dirt, leaves, insects, and pesticide residues.

Some facilities use mechanical brushes that gently scrub apple surfaces while water jets wash away loosened debris.

Washing typically takes 30-45 minutes, ensuring complete removal of contaminants while minimizing apple damage.

Step 4: Grinding & Maceration (Enzyme Treatment)

Washed apples are fed into industrial grinders or hammer mills that crush them into small pieces (apple mash).

The crushed apples are moved to maceration tanks where pectinase enzyme (a natural enzyme that breaks down pectin—the glue holding apple cells together) is added.

The enzyme works at controlled temperature (40-45°C) for 60-90 minutes, breaking down cell walls and releasing juice that would otherwise remain trapped in the pulp, increasing juice yield by 5-10%.

Step 5: Hydraulic Pressing (Juice Extraction)

The enzyme-treated apple mash is loaded into large hydraulic presses—industrial equipment containing 288-500 fine filtering sleeves.

The press applies extreme pressure (1,500 kg/cm² or higher) to force juice through the filtering sleeves while retaining skins, seeds, stems, and other solids.

Pressing typically takes 20-30 minutes per load and extracts approximately 65-70% of the apples’ weight as liquid juice.

Step 6: Residue Management & Pomace Handling

After pressing, solid residue (pomace—skins, cores, seeds, pulp) is collected and can be pressed again with added water to extract remaining juice and increase overall yield.

Pomace that cannot be economically pressed further is dried and sold as livestock feed, processed for pectin extraction, or composted.

Some facilities sell pomace to other industries for apple cider vinegar or other apple-based products.

Clarification & Pasteurization: The Critical Processing Steps

Step 7: Sedimentation & Initial Filtering

Freshly pressed juice contains fine particles, starch, and suspended solids that make it cloudy.

The juice is transferred to large holding tanks where it sits at controlled temperature (20-30°C) for 2-8 hours, allowing the heaviest particles to settle to the bottom.

The clear supernatant (upper liquid layer) is then carefully decanted or pumped to the next stage, while settled solids are removed and composted.

Step 8: Enzymatic Clarification (Optional for Premium Products)

For ultra-clear juice (as opposed to cloudy juice), pectinase and cellulase enzymes are added to the settled juice at 40°C for 60+ minutes.

These enzymes break down remaining pectin and plant cell wall materials, allowing suspended solids to coagulate and settle more efficiently.

This enzymatic clarification improves juice clarity while preserving flavor and nutritional value better than other clarification methods.

Step 9: Mechanical Clarification & Filtration

The enzymatically treated juice passes through mechanical clarification equipment including belt presses, disk separators, or centrifuges that further remove suspended solids.

Fine membrane filters (0.5-5 microns) then filter the juice to remove the smallest particles, producing crystal-clear juice if clarity is desired.

For cloudy juice (which retains more pulp and fiber), this step is reduced or skipped entirely, preserving the juice’s natural appearance and higher fiber content.

Step 10: pH Adjustment & Flavor Balancing

Clarified juice’s natural pH (typically 3.5-4.0) and flavor components are tested and adjusted if necessary.

Sugar content (Brix) is measured—apple juice naturally contains 11-14% sugar depending on apple variety, no sugar addition required.

Minor adjustments (natural acid, Vitamin C for preservation) may be made to achieve consistency across batches.

Step 11: Pasteurization (Heat Treatment for Safety)

Clarified juice is pumped through a heat exchanger where it’s rapidly heated to 85-95°C (185-203°F) for 10-120 seconds depending on target shelf-life.

This brief heat treatment kills bacteria, yeasts, and molds naturally present in fruit juice—eliminating spoilage organisms and pathogens like E. coli.

The short heating time preserves flavor, color, and nutritional value (like Vitamin C) far better than extended heating.

Step 12: Rapid Cooling

Immediately after heat treatment, the pasteurized juice is rapidly cooled back to 65-70°C in a second heat exchanger section.

Quick cooling stops the pasteurization process and prevents flavor/nutrition loss from prolonged heat exposure.

The entire pasteurization cycle—heating and cooling—takes only 30-60 seconds.

Step 13: Temporary Storage & Quality Control

Pasteurized juice is transferred to stainless steel storage tanks maintained at 5-10°C (refrigerated) to prevent any post-pasteurization contamination.

Before bottling, final samples are tested for pH, color, viscosity, flavor, and microbial load (sterility tests).

Only juice passing all quality parameters is released for bottling; off-spec batches are diverted for concentrate production or disposal.

Bottling, Packaging & Distribution

Step 14: Filling into Bottles or Cartons

Refrigerated apple juice is pumped from storage tanks to automated filling machines operating at high speed (100-500 containers per minute depending on facility).

Filling machines dispense precise volumes (typically 250ml, 500ml, 1liter, or larger bulk sizes) with accuracy better than ±1%.

For hot-filled products, juice may be heated to 70-80°C before filling, which provides additional pasteurization effect and allows aseptic cooling in the container.

Step 15: Sealing & Capping

Immediately after filling, bottles are sealed with caps or lids applied by automated capping machines at precise torque (tightness) to prevent leakage without over-tightening.

For carton products, tops are folded and sealed; for glass bottles, caps are crimped; for PET plastic, screw caps are torqued to specification.

Each sealed container is checked for proper sealing—defective containers are automatically rejected.

Step 16: Labeling & Batch Coding

Sealed bottles move through labeling machines that apply product labels, nutrition facts panels, ingredient lists, barcode, and manufacturer information.

Batch codes and expiration dates are printed using thermal transfer or laser marking systems, enabling traceability and recall capability if needed.

Vision inspection verifies label placement, legibility, and alignment before products leave the production line.

Step 17: Case Packing & Storage

Labeled bottles are robotically packed into cardboard cases (typically 6-24 bottles per case depending on bottle size) and placed on pallets.

Cases are wrapped with plastic film and loaded into cold rooms or refrigerated trucks for distribution.

Properly pasteurized and packaged apple juice remains fresh for 2-3 weeks in retail refrigeration, or 6+ months if frozen.

Step 18: Distribution & Retail Display

Packaged apple juice is distributed via refrigerated trucks to retail stores, maintaining temperature control throughout logistics.

In stores, juice is displayed in refrigerated sections at 32-40°F (0-4°C) to maintain quality and safety.

Consumers purchase and consume within the printed “best by” date for optimal flavor and nutritional value.

Why This Process?

Enzyme treatment (pectinase) breaks down pectin and cell walls, dramatically increasing juice extraction and reducing waste.

Pasteurization kills pathogenic bacteria and spoilage organisms while the brief heating time preserves flavor and nutrition far better than extended heat treatment.

Clarification removes haze-causing particles while enzymatic treatment preserves beneficial polyphenols and fiber—creating superior juice compared to non-enzymatic methods.

Rapid cooling after pasteurization halts heat damage and preserves volatile flavor compounds that would otherwise degrade with prolonged heating.

What About Additives & Concentrate?

100% pure apple juice contains only apples and water (plus optional Vitamin C as preservative)—no added sugars, no artificial ingredients.

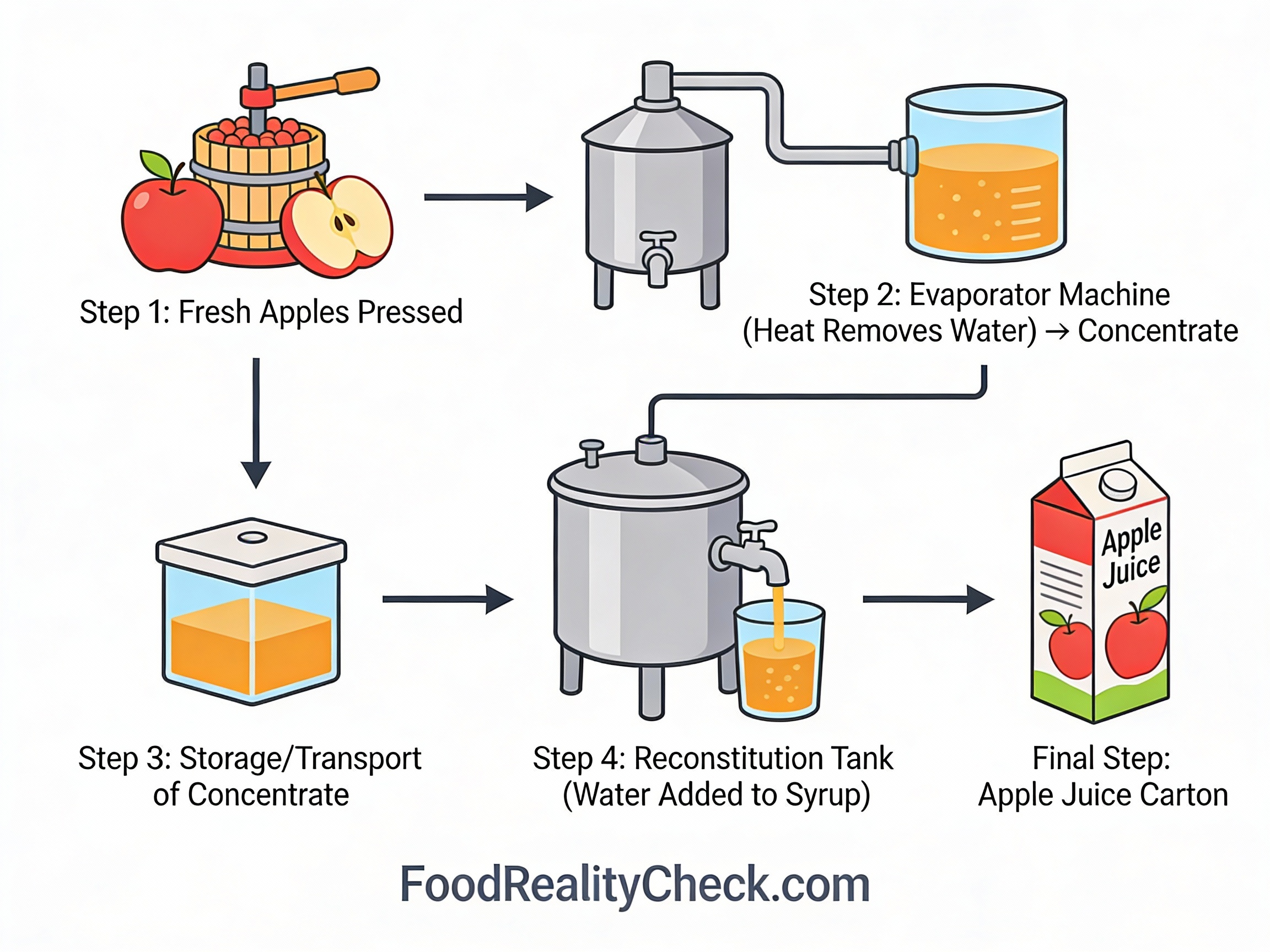

Some commercial juices are made from concentrate (juice with 90% water removed)—then rehydrated with water back to original consistency. This doesn’t change nutritional value but allows cheaper transportation and longer storage.

Some apple juice “drinks” or “blends” are only 10-50% apple juice, with added sugar, water, and other juices—check the label for “100% juice” to ensure you’re getting pure apple juice.

The Bottom Line

Apple juice production is a carefully controlled process that transforms fresh apples into shelf-stable juice through enzymatic extraction, clarification, pasteurization, and precise packaging.

The key innovations—enzyme-assisted pressing and rapid pasteurization—maximize juice yield and flavor preservation while ensuring food safety and extending shelf-life.

Now you understand exactly how apples go from orchard to your glass through pressing, clarification, heat treatment, and modern food processing technology.