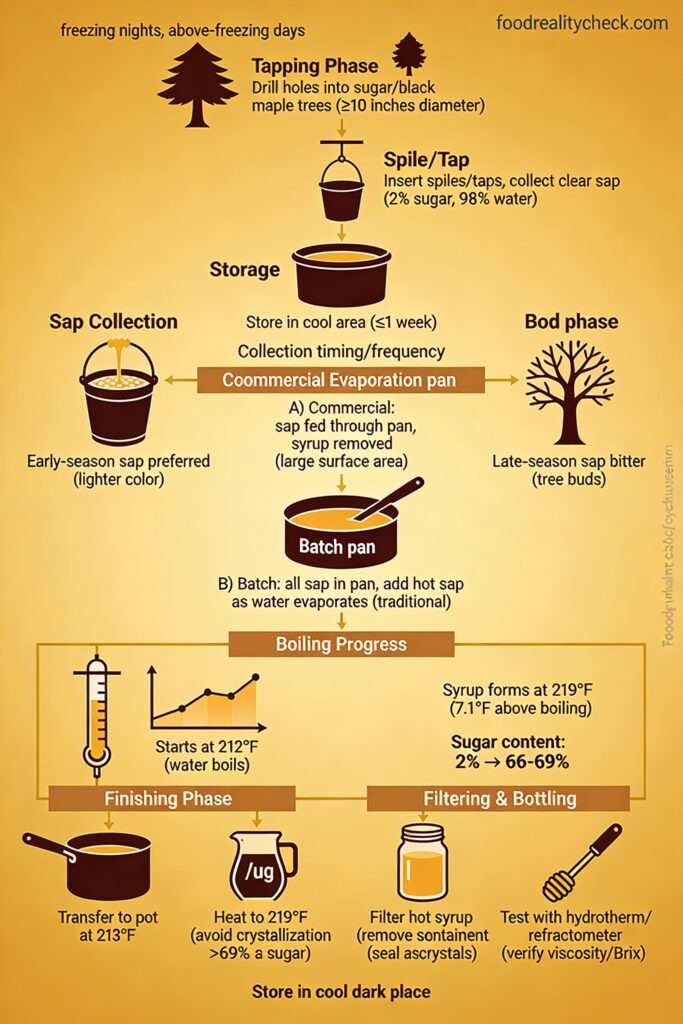

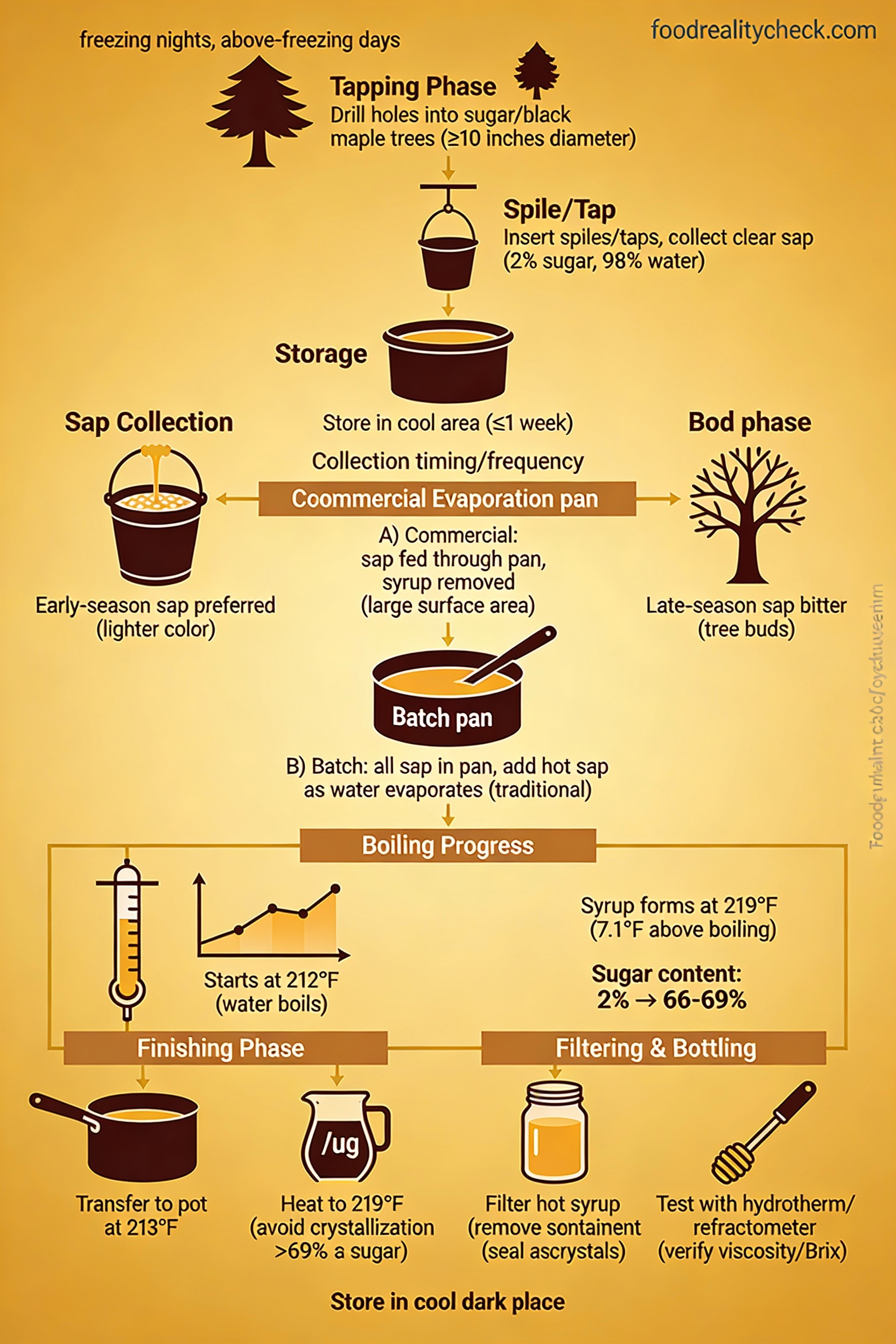

How Is Maple Syrup Made?

From tree sap to golden sweetener through tapping, boiling, and precise temperature control.

The Overview

Maple syrup is produced by tapping sugar maple trees in early spring, collecting the flowing sap, and concentrating it through intense boiling that removes 97% of its water content while developing the distinctive maple flavor through heat-driven chemical reactions.

The manufacturing process is entirely seasonal—limited to 4-8 weeks in spring when trees are actively flowing—and relies on temperature control during boiling, precise finish point detection, and careful straining to create the golden-to-dark syrup consumers expect.

Here’s exactly how tree sap transforms into maple syrup through boiling and chemistry.

🥘 Main Ingredients & Materials

• Sugar maple tree sap (only ingredient)

• Heat (wood or oil-fired)

• Reverse osmosis equipment (optional, modern producers)

• Defoaming agents (optional, to prevent boiling over)

Step 1: Maple Tree Selection & Preparation

Sugar maple trees are selected based on age (40+ years for optimal sap flow) and health—only healthy, mature trees produce quality sap.

In late winter/early spring, small holes (7/16-inch diameter) are drilled 1.5-2 inches into the sapwood—deep enough to reach actively flowing sap but not so deep as to damage the tree.

Typically, 1-3 taps are installed per tree depending on trunk diameter, with trees spaced apart to ensure adequate sap flow.

Step 2: Tapping & Sap Collection

Spouts (taps) are inserted into drilled holes, and collection buckets or tubing lines are attached to drain flowing sap.

Sap naturally flows out due to pressure differences as the tree awakens in spring—no pumping required. Ideal conditions for sap flow are freezing nights (below -4°C) followed by warm days (above 5°C), creating pressure buildup that forces sap out.

A single mature tree can produce 30-50 gallons of sap per season, though only 1-1.5 gallons of finished syrup (about 2-3% yield).

💡 Did You Know? Maple sap is roughly 98% water and only 2% sugar when collected. It takes 40-50 gallons of sap to make just 1 gallon of maple syrup—the tremendous water removal through boiling is what concentrates the natural sugar and develops the distinctive maple flavor. This extreme concentration is why maple syrup is expensive compared to other sweeteners.

Step 3: Sap Transport & Storage

Collected sap is transferred in food-grade containers or through collection tubing to the sugar house (boiling facility).

Fresh sap is best processed immediately while still sterile—any delay allows naturally present bacteria to ferment the sugars, producing undesirable sour flavors.

If storage is necessary, sap is refrigerated at 2-4°C to slow bacterial growth, with a maximum storage time of 7-10 days before boiling must begin.

Step 4: Reverse Osmosis (Modern Efficiency Step, Optional)

Modern large-scale operations use reverse osmosis (RO) machines that filter sap under pressure, removing water molecules while retaining sugars and flavor compounds.

RO can remove up to 75-80% of water before boiling begins, dramatically reducing fuel consumption and boiling time—a critical efficiency improvement for commercial operations.

RO-concentrated sap enters the boiler already at 6-8% sugar (vs. 2% raw sap), reducing boiling time from 8+ hours to 2-3 hours.

Step 5: Pre-Boiling Filtration

Sap (fresh or RO-concentrated) is filtered through fine screens or cloth to remove particulates like bark, leaves, and minerals that would cloud the final syrup.

Filtration is critical for clarity—unfiltered sap produces cloudy, gritty syrup.

The filtered sap is now ready for the most important step: boiling.

Boiling: The Heart of Maple Syrup Making

Step 6: Heating the Evaporator Pans

Sap is loaded into large stainless steel or cast iron evaporator pans heated from underneath by wood fire, oil burner, or gas flame at extremely high temperature (typically 200+ kW input for large operations).

The evaporator is divided into chambers (traditionally 2-4 separate zones) with different temperatures to gradually concentrate the sap.

Sap enters the coolest chamber first and flows through progressively hotter chambers as water boils away, exiting at the finish chamber where final concentration occurs.

Step 7: Active Boiling & Water Evaporation

Sap boils vigorously in the evaporator, with water rapidly evaporating while sugars concentrate and heat drives the Maillard reaction—a browning reaction between amino acids and sugars that creates maple flavor and color.

Boiling continues for hours (2-8 hours depending on sap quantity and RO pre-treatment) as the syrup gradually darkens from clear/light amber to medium amber or dark amber depending on heat exposure.

Temperature control is constant—excessive heat darkens syrup excessively (creating dark or “cooking molasses” grades); insufficient heat produces light syrup.

Step 8: Finish Point Detection (Critical Phase)

The most critical moment in maple syrup production is detecting the exact finish point—when the syrup has concentrated to exactly 66-67% sugar (the legal standard for finished maple syrup).

Traditionally, this is tested by dipping a wooden stick in the boiling syrup and observing how it drips when cooled—the syrup ribbons at 66-67% Brix (sugar content).

Modern producers use hydrometers, refractometers, or automatic electronic sensors that trigger the draw-off valve when the exact finish point is reached.

Step 9: Draw-Off & Hot Syrup Transfer

When finish point is reached, the hot syrup (approximately 104°C / 220°F) is drawn off from the finish chamber into holding tanks or directly into bottles.

Hot syrup is drawn continuously throughout the boiling season—batches of finished syrup are produced every 2-4 hours depending on sap volume and boiling rate.

The thick, viscous syrup flows slowly at this temperature—cooling would make it impossible to pour.

Step 10: Fine Filtration (Post-Boiling)

Hot syrup from the draw-off is filtered through fine cloth, paper, or diatomaceous earth filters to remove sediment (sand, minerals, and other particles that settled out during boiling).

Filtration while hot is essential—cold syrup is too viscous to filter efficiently. The hot filtering removes all visible cloudiness and sand particles.

Filtered syrup is now clear, clean, and shelf-stable.

Step 11: Cooling & Creaming (For Cream Syrup/Butter)

For most liquid syrup, finished syrup is cooled gradually and bottled at room temperature.

For maple cream (soft, spreadable maple candy), syrup is cooled to 40-50°C, then agitated vigorously while cooling to 35°C—this controlled crystallization creates tiny sugar crystals, producing creamy texture.

The agitation must be precise—too much creates grainy texture; too little prevents crystallization.

Bottling, Pasteurization & Distribution

Step 12: Pasteurization (Optional but Common)

Most commercial maple syrup is gently heated to 82°C (180°F) for 15 seconds to kill any residual yeast or mold that might cause fermentation during storage.

Pasteurization extends shelf-life indefinitely (unpasteurized syrup can ferment if contaminated) while the brief heating causes minimal flavor or color change.

The syrup is cooled back to 70-80°C before bottling to maintain flow properties.

Step 13: Filling into Bottles

Hot or warm syrup (70-80°C) is filled into glass bottles or plastic containers using automated filling machines at 50-200 containers per minute depending on facility size.

Fill volumes are measured precisely—typically 250ml, 500ml, or 1-liter sizes—with accuracy better than ±1%.

Hot filling provides built-in pasteurization—the residual heat inside the bottle sterilizes the headspace and helps form a good seal.

Step 14: Capping & Cooling

Filled bottles are capped immediately after filling—hot syrup inside the bottle creates internal pressure that helps form a tight seal.

Caps are applied at precise torque to ensure a good seal without over-tightening.

Hot bottles cool on conveyors or in air tunnels to room temperature, at which point the internal vacuum helps keep the seal tight.

Step 15: Labeling & Grading Verification

Cooled bottles move to labeling machines that apply the producer’s label showing grade (Light Amber, Medium Amber, Dark Amber), ingredients (100% pure maple syrup), and nutritional information.

Grade labels match the syrup’s actual color and flavor intensity—produced through careful boiling time control.

Batch codes and production dates are printed for traceability.

Step 16: Case Packing & Storage

Labeled bottles are packed into cases (typically 12 bottles per case) and stacked on pallets for storage in cool, dry conditions.

Maple syrup is shelf-stable at room temperature for 1-2 years or indefinitely if refrigerated after opening.

Syrup is distributed to retailers via ambient temperature trucks—refrigeration not required during distribution.

Step 17: Retail Display & Consumer Use

Bottled maple syrup is displayed in retail stores in shelf-stable sections, not requiring refrigeration until opened.

Consumers use the syrup within 1-2 years of purchase—excellent shelf stability and no preservatives required.

Once opened, refrigeration is recommended to prevent mold growth if the syrup becomes contaminated with water.

Why This Process?

Boiling concentrates sap from 2% to 66% sugar—this extreme concentration creates a product that won’t ferment or spoil, providing natural preservation without additives.

The Maillard reaction during boiling creates hundreds of flavor compounds that give maple syrup its distinctive taste—boiling time entirely determines flavor intensity and color.

Precise finish point detection ensures consistent quality—syrup at 66-67% Brix has the perfect viscosity that’s pourable at room temperature yet thick enough to cling to food.

Reverse osmosis pre-treatment dramatically reduces fuel consumption and boiling time, improving economics while producing identical final quality.

Maple Syrup Grades & Variations

Maple syrup is graded by color and flavor intensity—all determined by boiling time:

• Golden Delicate: Lightest color, mildest flavor, shortest boiling time

• Amber Rich: Medium color, classic maple flavor, moderate boiling time

• Dark Robust: Dark color, strong maple flavor, longer boiling time

• Very Dark Strong: Darkest color, most intense flavor, longest boiling time

Pure maple syrup contains only one ingredient: maple sap concentrate. No additives, no preservatives, no processing aids required.

Some products labeled “maple-flavored syrup” are actually mostly corn syrup with small amounts of real maple syrup—check labels for “100% pure maple syrup.”

The Bottom Line

Maple syrup production is a simple yet elegant process—collect sap, boil away 97% of its water, stop at exactly the right moment, and bottle. That’s it—no additives, no processing aids, just heat-driven chemistry.

The Maillard reaction during boiling creates all the distinctive maple flavor—boiling time is the only variable controlling the final product’s character.

Now you understand exactly how tree sap becomes maple syrup through intensive boiling, precise finish point detection, and careful temperature management.