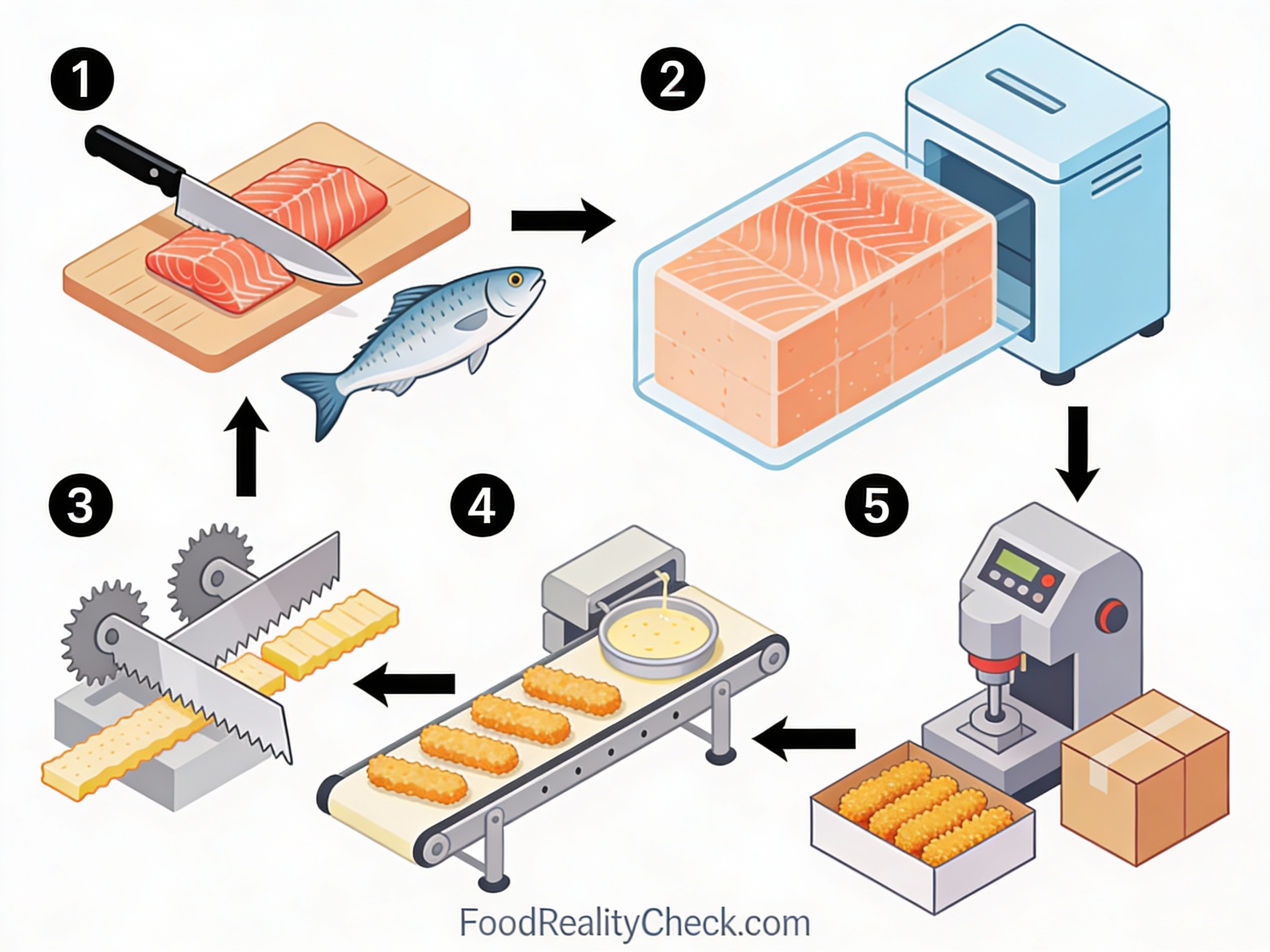

How Are Fish Sticks Made?

From fresh fish fillets to breaded, frozen portions through cutting, battering, breading, and flash-freezing.

The Overview

Fish sticks are made by processing fish fillets into uniform stick-shaped pieces, coating them in a protective batter, applying seasoned breadcrumb coating, partially cooking them, and flash-freezing them to create a shelf-stable product that consumers finish cooking at home.

The manufacturing process converts bulk fish fillets into standardized, consistent products through automated cutting, portioning, breading, and freezing at industrial scale—producing thousands of identical fish sticks daily from fresh fish processed the same day.

Here’s exactly how fish fillets transform into the convenient frozen portions you find in the grocery store.

🥘 Main Ingredients

• Fresh fish fillets (typically pollock, cod, or haddock)

• Water

• Wheat flour (for batter)

• Breadcrumbs (panko or standard)

• Vegetable oil (for frying)

• Salt and seasonings

• Optional: binding agents, flavor enhancers

Step 1: Fish Receiving & Quality Assessment

Fresh fish fillets arrive at the processing facility on ice, typically within 24 hours of being caught (to maintain freshness and food safety).

Each batch is inspected for quality: color (bright white or pale), firmness (no mushiness), odor (clean oceanic smell, no ammonia), and absence of bruising or blemishes.

Fish failing quality standards is rejected and diverted to other uses (fish meal, pet food) or disposed of—only premium fillets proceed to fish stick production.

Step 2: Fileting & Trimming (If Using Whole Fish)

If whole fish is received, it’s cleaned, gutted, and mechanically filleted using automated filleting machines that extract fillets with minimal waste.

Most modern fish stick manufacturers receive pre-cut frozen fillets (handled by specialized fishing companies), skipping this step for efficiency.

Fillets are trimmed to remove bones, skin, and bloodlines—any remaining bones would create food safety hazards and unpleasant eating experience.

Step 3: Portion Cutting & Standardization

Fresh or thawed fillets are placed on automated cutting equipment that slices them into uniform stick shapes—typically 3-4 inches long by 0.5-1 inch wide.

Precision cutting ensures consistency—each stick weighs approximately 28-35 grams and is the same shape as every other stick.

Uniform size is critical for even baking when consumers cook the product at home—oversized sticks bake unevenly.

Step 4: Pre-Cooking/Freezing Preparation

Cut fish pieces are placed on conveyor belts and passed through an industrial freezer (blast freezer or plate freezer) at -30 to -40°C for 15-30 minutes.

This flash-freezing firms up the fish, making it rigid enough to handle the breading and frying process without falling apart or becoming mushy.

Freezing also stops bacterial growth and preserves freshness—fish can now be stored for weeks until the next processing step.

Step 5: Batter Coating (First Protective Layer)

Flash-frozen fish pieces are removed from freezing and immediately passed through a batter coating system that applies a thin, protective egg-based or water-based batter.

The batter (made from flour, water, and optional seasonings) coats all surfaces and adheres to the fish, protecting delicate flesh from oil during frying and helping breadcrumbs stick.

Batter application is precisely controlled—too little and breadcrumbs don’t adhere well; too much and the final product becomes soggy.

Step 6: Breadcrumb Coating (Second Layer)

Battered fish pieces are conveyed directly to a breading station where they’re tumbled in seasoned breadcrumbs (panko or fine breadcrumbs depending on desired texture).

The breadcrumb coating adheres to the wet batter, creating a golden, crunchy exterior when cooked.

Breadcrumb composition varies—panko (Japanese breadcrumbs) creates a crunchier, more appealing texture than fine breadcrumbs.

Cooking, Freezing & Packaging

Step 7: Deep Frying (Partial Cooking)

Breaded fish sticks are conveyed through industrial deep fryers filled with vegetable oil heated to 165-175°C (330-350°F) for 2-3 minutes.

Frying cooks the fish exterior and bread coating until light golden brown—but the interior remains partially cooked (not fully done).

This partial cooking kills surface bacteria while the interior remains slightly undercooked for consumer finishing—preventing the product from being overdone after home baking.

Step 8: Draining & Oil Removal

Hot fried fish sticks exit the fryer onto vibrating screens or conveyor belts that allow excess oil to drain away.

Some facilities use centrifugal dryers that spin sticks at high speed, removing oil through centrifugal force.

Proper oil removal prevents sogginess and oxidation during frozen storage—residual oil can go rancid over time, degrading flavor and creating off-odors.

Step 9: Cooling Before Final Freezing

Oil-drained fish sticks are cooled on conveyors at room temperature for 10-15 minutes before final freezing.

Cooling hardens the breading and allows the interior to continue cooking slightly from residual heat.

This intermediate cooling prevents excessive condensation and ice crystals when the still-hot sticks enter the final freezer.

Step 10: Final Flash-Freezing

Cooled fish sticks are conveyed through a final blast freezer at -35 to -40°C for 15-30 minutes, solidifying them completely.

Flash-freezing creates small ice crystals throughout the product, preserving texture and flavor better than slow freezing (which creates large ice crystals that damage cell structure).

Once frozen solid, sticks are shelf-stable at -18°C or colder for 12+ months.

Step 11: Metal Detection & Safety Inspection

Frozen fish sticks pass through metal detection equipment that scans for any metal fragments (from equipment wear, machinery contact, or external contamination).

Any stick detected with metal is automatically rejected and diverted.

Vision inspection systems also scan for defects: cracks, improper shape, or discoloration.

Step 12: Portioning Into Boxes

Inspected frozen fish sticks are counted and packed into cardboard boxes (typically 10-16 sticks per box depending on target weight: 227g / 8oz is standard).

Automated packing machines count sticks and fill boxes at rates of 100+ boxes per minute, with precise weight control ensuring each box contains exactly the right number of sticks.

Boxes are sealed with glue or ultrasonic sealing to protect product during handling and storage.

Step 13: Labeling & Nutritional Information

Sealed boxes are labeled with brand name, product description, nutrition facts panel, ingredient list, cooking instructions, and allergen warnings.

Batch codes and expiration dates are printed on boxes for traceability (typically 12-18 months from manufacturing).

Vision inspection verifies label placement, legibility, and alignment before boxes proceed to case packing.

Step 14: Case Packing & Cold Chain Storage

Labeled fish stick boxes are packed into larger cardboard cases (typically 10-12 boxes per case, totaling roughly 2.3-2.7 kg / 5-6 lbs per case).

Cases are stacked on pallets and loaded into freezer trucks or frozen warehouses maintained at -18°C or below.

Proper cold chain maintenance is critical—any thawing and re-freezing would degrade quality.

Step 15: Distribution & Retail Display

Packaged fish sticks are distributed via refrigerated/frozen trucks to retail stores, maintaining continuous cold chain from factory to store.

In stores, fish sticks are displayed in frozen food sections at -18°C or colder alongside other frozen seafood and prepared meals.

Consumers purchase and store in their home freezers until ready to cook—typically baked at 200-220°C for 15-20 minutes until heated through and external coating crisps.

Why This Process?

Flash-freezing before breading firms up delicate fish, preventing it from falling apart or becoming mushy during the breading and frying process.

Partial cooking (par-cooking) ensures surface bacteria are killed while allowing consumers to finish cooking for desired doneness—balancing safety with convenience.

Batter layer protects delicate fish from direct oil contact, preventing greasiness and excessive oil absorption.

Breadcrumb coating provides desirable texture contrast—crispy exterior with tender, moist interior when cooked properly at home.

What About Fish Species & Quality?

Most commercial fish sticks use:

• Pollock: Mild white fish, widely available, economical

• Cod: Slightly firmer, slightly richer flavor

• Haddock: Fine, delicate flavor (more premium)

• Other species: Some brands use tilapia, flounder, or other white fish

Fish quality directly determines final product quality—premium products use fresh wild-caught fish processed the same day; budget products use frozen fish imported from far away.

Food safety is critical—all fish undergoes pressure-freezing (blast freezing) to kill parasites before being thawed for breading, or remains frozen throughout the entire process to eliminate parasite risk.

The Bottom Line

Fish stick production is a sophisticated food processing operation that transforms fresh fish fillets into convenient, shelf-stable frozen portions through precision cutting, breading, partial cooking, and flash-freezing.

The key innovation—partial pre-cooking—allows frozen fish sticks to be prepared quickly at home while maintaining food safety and quality.

Now you understand exactly how fish fillets become the convenient frozen portions through industrial breading, frying, and flash-freezing technology.