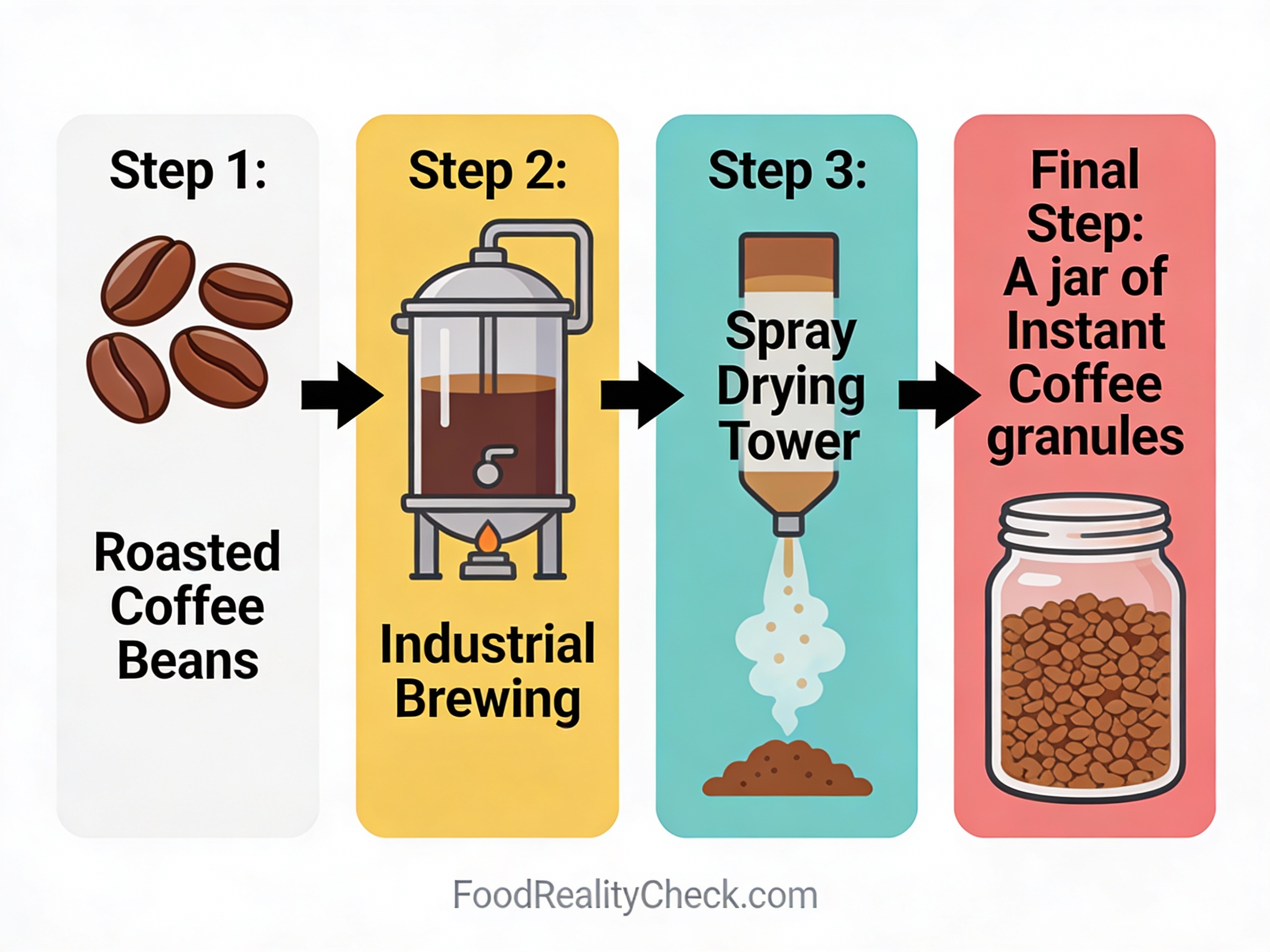

How Is Instant Coffee Made?

From roasted beans to soluble crystals through extraction, concentration, and drying.

The Overview

Instant coffee is made by roasting and grinding coffee beans, extracting the soluble compounds with hot water, concentrating the liquid extract under vacuum, and dehydrating it using spray-drying or freeze-drying to create soluble powder that instantly dissolves in hot water.

The manufacturing process is the inverse of brewing—instead of hot water extracting flavor from beans, coffee manufacturers extract flavor from beans, then remove the water, leaving behind pure soluble coffee crystals that consumers reconstitute with hot water at home.

Here’s exactly how coffee beans transform into instant powder through industrial extraction, concentration, and freeze-drying.

🥘 Main Ingredients & Materials

• Green (unroasted) coffee beans

• Water (for extraction)

• Heat (for roasting and extraction)

• Optional: chicory root (for some blends)

• No additives (pure instant coffee)

Step 1: Green Bean Selection & Roasting

Green (unroasted) coffee beans are sourced from suppliers around the world—Ethiopia, Colombia, Vietnam, Indonesia—and arrive at the instant coffee factory in bulk bags (50-60 kg each).

Beans are inspected for quality, sorted to remove defects and debris, then roasted in large cylindrical roasters at 180-220°C (356-428°F) for 10-15 minutes depending on desired roast level (light, medium, dark).

Roasting develops the hundreds of flavor compounds that make coffee taste like coffee—green beans taste grass-like and bitter before roasting.

Step 2: Grinding the Roasted Beans

Roasted beans are cooled and transferred to industrial grinders where they’re ground into a fine powder (consistency of all-purpose flour).

The grind size for instant coffee is finer than for filter coffee—smaller particles maximize surface area for water extraction.

Ground coffee is typically used immediately after grinding, as the freshly ground aroma and flavor compounds begin to escape within hours of grinding.

Step 3: Hot Water Extraction (The Critical Step)

Ground coffee is mixed with hot water (typically 160-175°C / 320-350°F) in large extraction vessels (up to 10,000 liters) at precise water-to-coffee ratios (typically 3-5:1 water to ground coffee by weight).

The extraction takes 30 minutes to several hours—during this time, hot water dissolves soluble compounds from the coffee solids: caffeine, flavor compounds, oils, proteins, and sugars.

The result is a dark brown liquid (coffee extract) containing all the flavor but still with insoluble solids (grounds) suspended in it.

Step 4: Filtration & Separation

The coffee extract (containing both soluble compounds and insoluble grounds) is filtered through fine screens or cloth to separate the liquid extract from solid waste.

Alternatively, centrifuges spin the extract at high speed (up to 5,000 RPM), using centrifugal force to separate heavy solids from lighter liquid.

The resulting liquid extract is clean, clear, and dark brown—containing all soluble coffee compounds and ready for the next step.

Step 5: Vacuum Concentration (Water Removal)

The filtered extract is transferred to vacuum evaporators where it’s heated under reduced pressure (0.1 atmospheres or lower) at lower temperatures (45-70°C) than atmospheric evaporation would require.

Lower temperature vacuum evaporation prevents heat damage to delicate flavor compounds that would degrade if exposed to high heat.

Water is boiled away under vacuum, concentrating the coffee extract from roughly 15-20% solids to 30-40% solids (similar to strong syrup consistency).

Step 6: Final Concentration Control

The concentrate is carefully monitored during vacuum evaporation—operators sample it regularly to verify exact solids concentration and flavor development.

Once the desired concentration is reached (typically 35-40% solids), the concentrate is cooled to 20-30°C in preparation for drying.

At this stage, the concentrate is extremely bitter and concentrated—completely unpalatable as-is, requiring only water to dissolve and become drinkable coffee.

Drying: Converting Liquid to Powder

Step 7: Spray-Drying (Most Common Method)

The concentrated coffee extract is transferred to a spray dryer—a large chamber where the liquid is atomized into fine droplets at the top and falls through hot air (160-200°C) as it descends.

As the droplets fall through the hot air chamber, water instantly evaporates, leaving behind tiny solid coffee particles that fall to the bottom of the chamber.

Spray-drying is incredibly fast—the entire drying process takes seconds, preserving volatile flavor compounds better than slow drying methods.

Step 8: Freeze-Drying (Premium Method)

For premium instant coffee, the concentrated extract is frozen solid at -30 to -40°C, then placed in a vacuum chamber where ice sublimes directly into water vapor without melting.

Freeze-drying takes 12-24 hours (much longer than spray-drying) but produces superior results: better flavor preservation, better aroma retention, and lighter color.

Freeze-dried instant coffee typically costs 20-40% more than spray-dried, but provides noticeably better coffee taste and aroma.

Step 9: Particle Size Sorting & Collection

Dried coffee particles exit the spray dryer or freeze dryer and are collected in settling chambers or cyclones.

Particles are sieved through screens to separate them by size—finer particles (which dissolve faster) are collected separately from coarser particles.

The finest particles are typically instant coffee powder; coarser particles are often recycled back through the process or sold separately as “instant coffee crystals.”

💡 Did You Know? Instant coffee “crystals” (the visible chunks in instant coffee jars) are created by agglomerating (combining) spray-dried particles into larger, more visible crystals. This is purely cosmetic—consumers perceive larger crystals as “better quality.” The crystals dissolve no faster than fine powder, but look more impressive in the jar and feel more premium to handle.

Step 10: Agglomeration (Creating Visible Crystals, Optional)

For products marketed as “instant coffee crystals,” the fine spray-dried powder is deliberately moistened slightly (5-8% water added back) and re-dried to cause particles to clump together into visible crystals.

These crystals are purely cosmetic—they dissolve no faster than fine powder, but look more impressive and feel premium to consumers.

Not all instant coffee is agglomerated; many budget products remain fine powder, which is functionally identical.

Step 11: Quality Control & Moisture Testing

Dried instant coffee is tested for moisture content (should be 2-4% residual water), color consistency, particle size distribution, and flavor profile.

Samples are reconstituted with hot water and evaluated by trained tasters for taste, aroma, and mouthfeel.

Batches that fail quality specifications are diverted for re-processing or disposal.

Step 12: Packaging into Jars or Packets

Quality-approved instant coffee is filled into glass jars or plastic containers (typical sizes: 100g, 200g, 500g) at rates of 100+ jars per minute using automated filling equipment.

Fill weights are precisely controlled—modern equipment maintains accuracy to within ±0.5 grams.

Jars are capped and sealed immediately after filling to prevent moisture absorption from air.

Step 13: Labeling & Vacuum Sealing

Filled jars are labeled with brand name, roast level (light, medium, dark), “100% pure instant coffee,” nutrition information, and brewing instructions.

Some premium products include vacuum-seal lids that pump air out of the jar when first opened, maintaining freshness for months after opening.

Batch codes and “best by” dates are printed for traceability (typically 2-3 years from manufacturing).

Step 14: Case Packing & Storage

Labeled jars are packed into cardboard cases (typically 12-24 jars per case) and stacked on pallets for storage.

Instant coffee is stored in cool, dry conditions (15-22°C, 30-40% humidity) to prevent moisture absorption and preserve aroma.

Proper storage maintains freshness and flavor for 2-3 years unopened.

Step 15: Distribution & Retail Display

Packaged instant coffee is distributed via ambient temperature trucks to retail stores, coffee shops, and food service establishments.

In stores, instant coffee is displayed in shelf-stable sections (coffee aisle) at room temperature—refrigeration is unnecessary and actually undesirable (temperature fluctuations cause moisture absorption).

Consumers purchase and consume within 2-3 years of manufacturing, or within 1-2 months of opening for optimal flavor.

Why This Process?

Extraction at high temperature quickly dissolves soluble coffee compounds, creating strong concentrate in 30+ minutes versus 4-5 minutes home brewing.

Vacuum evaporation removes water at lower temperatures than atmospheric evaporation—preventing heat damage to delicate flavor compounds.

Spray-drying or freeze-drying removes 98-99% of water, creating shelf-stable powder with 2+ year shelf-life versus fresh brewed coffee that spoils in hours.

The entire process is the inverse of home brewing: extract → concentrate → dehydrate, then consumers reverse it at home: rehydrate → dissolve → drink.

Instant Coffee Quality Variations

Instant coffee quality varies dramatically by roasting quality, extraction method, and drying method:

• Budget instant coffee: Spray-dried, medium roast, lower grade beans = acceptable taste, thin body, less aroma

• Mid-range instant coffee: Spray-dried or freeze-dried, good roast level, decent beans = good taste, acceptable body

• Premium instant coffee: Freeze-dried, specialty roast, single-origin or premium blend beans = excellent taste, rich body, excellent aroma

All instant coffee is 100% pure coffee—no additives in true instant coffee (though some brands add chicory root or caramel coloring for darker appearance).

The Bottom Line

Instant coffee production is a sophisticated beverage processing operation that transforms roasted coffee beans into soluble powder through industrial extraction, vacuum concentration, and spray- or freeze-drying.

The process removes 98-99% of water from liquid coffee extract, creating shelf-stable powder that consumers reconstitute with hot water—the inverse of home brewing.

Now you understand exactly how roasted coffee beans become instant powder through extraction, concentration, and dehydration technology.