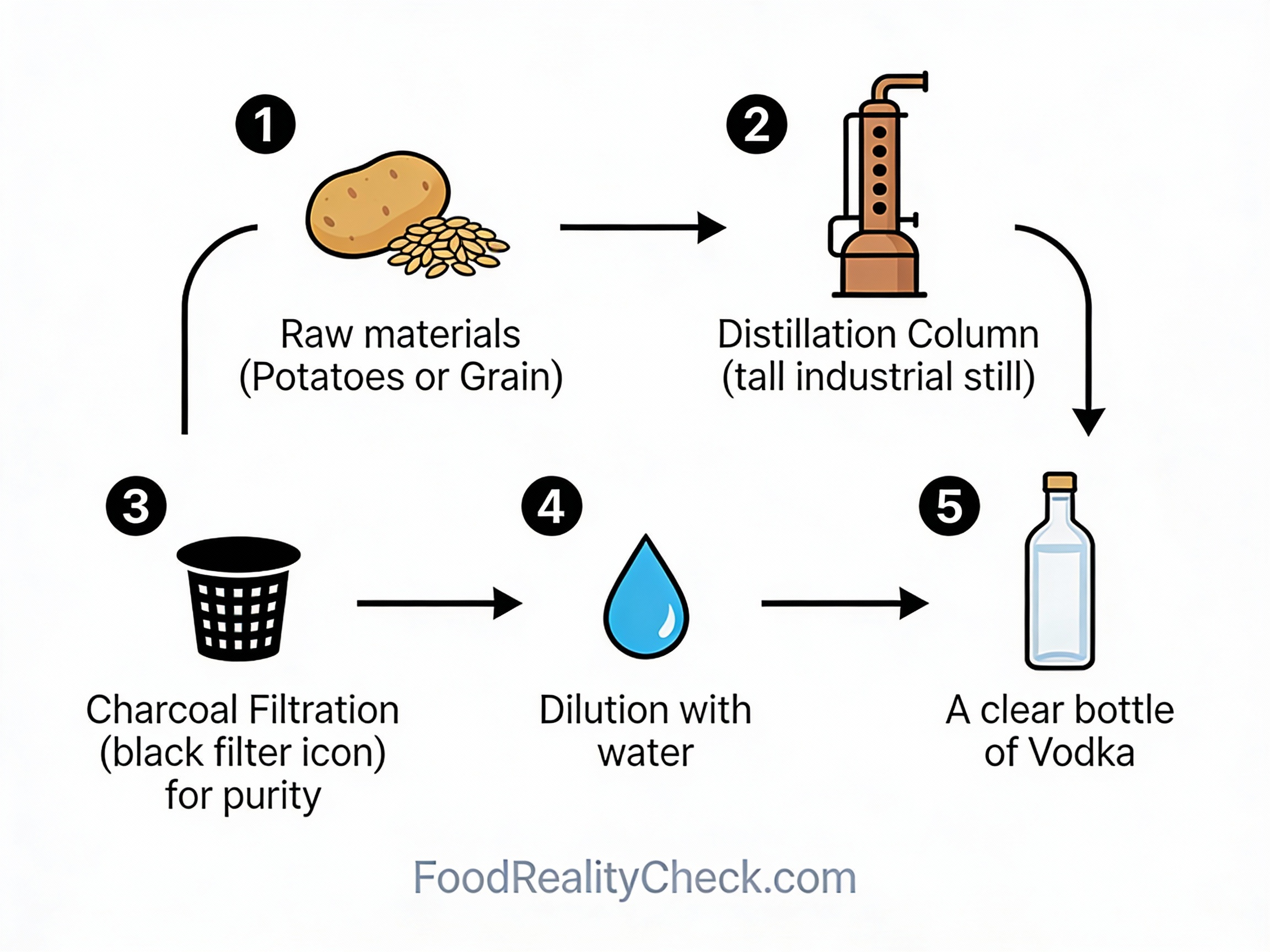

How Is Vodka Made?

From grain or potatoes to neutral spirit through fermentation, distillation, and purification.

The Overview

Vodka is made by fermenting carbohydrate-rich raw materials (grains, potatoes, fruits) with yeast to produce alcohol, distilling the fermented liquid multiple times in column stills to concentrate and purify the alcohol, filtering through activated charcoal and other media to remove impurities, and diluting with water to achieve the standardized 40% ABV (80 proof) bottled product.

The manufacturing process prioritizes purity and neutrality—vodka is intentionally stripped of flavor compounds through aggressive distillation and filtration, resulting in a colorless, nearly flavorless spirit that serves as a neutral base for mixed drinks rather than a distinctly flavored spirit like whiskey or gin.

Here’s exactly how grains or potatoes transform into the world’s most consumed spirit through fermentation, distillation, and industrial purification.

🥘 Main Raw Materials & Additives

• Grain (wheat, rye, barley, corn) OR potatoes OR fruits

• Yeast (Saccharomyces cerevisiae)

• Water (for fermentation and dilution)

• Enzymes (amylase, protease—to break down starches and proteins)

• Activated charcoal (for filtration)

• Optional: flavoring agents (in flavored vodkas)

Step 1: Raw Material Selection & Preparation

Vodka can be made from virtually any carbohydrate source—grain (wheat, rye, barley, corn) is most common, but potatoes, grapes, beets, and other crops are also used.

Grain is preferred because it’s cheaper, produces higher alcohol yields (15-18% ABV fermented), and is widely available.

Raw materials are inspected for quality—no moldy grain, no spoiled potatoes—and sorted to remove debris.

Step 2: Grain Milling & Enzyme Treatment (If Using Grain)

Grain is ground into flour to increase surface area for enzyme treatment.

Enzymes (amylase) are added to break down starch (long-chain carbohydrates) into simpler sugars (glucose) that yeast can ferment.

This enzymatic conversion is critical—raw starch cannot be fermented; it must be broken down into fermentable sugars first.

Step 3: Mashing & Sugar Extraction

Enzyme-treated grain (or mashed potatoes) is mixed with hot water (65-70°C) in large tanks to create a thick slurry called “mash.”

The heat activates the enzymes, accelerating starch-to-sugar conversion, and extracts sugars into the liquid.

Mashing typically lasts 1-2 hours, with the result being a sweet liquid called “wort” containing dissolved sugars and dissolved solids from the grain.

💡 Did You Know? Vodka production differs fundamentally from whiskey or gin in the goal: vodka is intentionally stripped of flavor and character to create a neutral spirit, while whiskey and gin preserve and develop flavors. A whiskey distiller tries to capture the subtle flavors of grain and wood aging; a vodka distiller tries to eliminate all flavors to create a blank canvas for mixed drinks.

Step 4: Cooling & Yeast Inoculation

The hot wort (containing dissolved sugars) is cooled to 15-25°C and transferred to fermentation vessels.

Commercial baker’s yeast (Saccharomyces cerevisiae) is added to consume sugars and produce alcohol.

Temperature control is critical—too cold and fermentation is slow; too warm and undesired flavor compounds are produced.

Step 5: Fermentation (Days to Weeks)

Yeast rapidly consumes sugars, producing ethanol (alcohol) and CO₂ gas through fermentation.

Fermentation typically lasts 3-10 days depending on yeast strain, temperature, and sugar content.

The result is “crude spirit” or “wash”—a liquid containing roughly 15-18% ABV, along with many undesired byproducts called “congeners” (acetaldehyde, methanol, esters, aldehydes) that give spirits their characteristic flavors and roughness.

Step 6: Distillation (Single or Multiple)

Fermented liquid is transferred to a distillation apparatus—typically a column still (a tall, cylindrical vessel with internal trays).

The liquid is heated to boiling (100°C), and alcohol vapors (which have a lower boiling point than water) rise up through the column while heavier water stays behind.

The alcohol vapor is collected at the top and condensed back into liquid called “distillate” or “spirit.”

Step 7: Separation of Heads, Hearts, & Tails

During distillation, the first vapors to condense (“heads”) and the last vapors (“tails”) contain undesired congeners and methanol.

Skilled distillers collect only the middle portion (“hearts”)—the purest, cleanest alcohol with minimum congeners.

Heads and tails are typically redistilled or discarded—they’re the source of hangovers and unpleasant flavors.

💡 Did You Know? Column stills (used for vodka, rum, and grain whiskey) are far more efficient at removing congeners than pot stills (used for single-malt whisky). A column still can achieve 95%+ alcohol purity in a single distillation; a pot still achieves only 60-70% in a single distillation. This is why vodka is so pure and neutral—it’s intentionally designed to distill away all flavors, whereas whisky keeps some congeners for character.

Step 8: Multiple Distillations (Optional, for Premium Quality)

Premium vodka producers distill multiple times (typically 2-5 distillations) to progressively remove more congeners and achieve higher purity.

Each additional distillation removes more flavor compounds, resulting in smoother, purer spirit.

Premium vodkas often claim “distilled 5 times” or similar—more distillations mean higher cost but smoother final product.

Purification & Finishing

Step 9: Filtration Through Activated Charcoal

The distilled spirit (typically 80-95% ABV at this point) is passed through activated charcoal filters that absorb remaining congeners, off-odors, and color.

Activated charcoal is extremely porous (like a sponge) and traps microscopic particles and odorous compounds, polishing the spirit to crystal clarity.

This charcoal filtration is distinctive of vodka production—it’s what creates the neutral, clean taste that vodka is known for.

Step 10: Additional Filtration (Premium Methods)

Premium vodkas often use multiple filtration stages: charcoal (as above), then sand filters, then micron filters (0.5-5 microns) that remove microscopic particles.

Some ultra-premium producers filter through quartz sand, diamond dust, or other specialized media marketed as creating “ultra-pure” vodka—though the taste difference is minimal.

The marketing appeal of “filtered through X times” or “filtered through diamond dust” is mostly for luxury positioning—the charcoal filtration is what matters most.

Step 11: Water Dilution to Final ABV

The distilled and filtered spirit (80-95% ABV) is too strong to drink—it would burn the mouth and throat.

Pure, demineralized water is added to dilute the spirit to the standard 40% ABV (80 proof in USA, though some products are 50% ABV or higher).

Water quality is critical—impurities in water would undo all the purification work done previously.

Step 12: Optional Flavoring (For Flavored Vodkas)

Plain vodka requires no flavoring—it’s intentionally neutral.

For flavored varieties (vanilla, citrus, berry, spiced), natural or artificial flavorings are added post-distillation.

Some producers infuse whole fruits, spices, or herbs into the spirit, then filter out the solids before bottling.

Step 13: Quality Control & Testing

Finished vodka is tested for alcohol content (must be 40% ABV ±0.5%), clarity, color (should be colorless), odor (should be neutral), and taste (trained tasters assess smoothness and any off-flavors).

Batches failing quality specifications are either re-distilled or diluted further if over-proof.

Micro-biological testing ensures no spoilage microbes are present.

Step 14: Bottling

Quality-approved vodka is filled into bottles (typically 750ml standard bottles, but also 1L, 1.75L, and miniature sizes) at 200+ bottles per minute using automated filling equipment.

Fill volumes are precisely controlled to exactly 750ml ±5ml for standard bottles.

The spirit is filtered one final time as it enters the bottling line, ensuring any particles are removed immediately before packaging.

Step 15: Capping & Sealing

Filled bottles are immediately capped with screw caps (most common) or cork closures (rare, more traditional).

Caps are torqued to precise tightness—tight enough to prevent leakage, but not so tight that consumers have difficulty opening.

Proper sealing prevents evaporation and contamination during storage.

Step 16: Labeling & Packaging

Sealed bottles are labeled with brand name, vodka category (plain, flavored, premium), alcohol content (40% ABV / 80 proof), country of origin, batch/lot code, and nutritional information.

Labels are designed to convey brand positioning—budget vodkas have simple labels, premium vodkas have elaborate, elegant designs.

Bottles are packed into cases (typically 12 bottles per case) for distribution.

Step 17: Storage & Distribution

Bottled vodka is stored in climate-controlled warehouses at room temperature (15-20°C) away from direct light.

Vodka has unlimited shelf-life—the high alcohol content (40% ABV) prevents spoilage indefinitely.

Distribution is via ambient temperature trucks to retailers, bars, and restaurants.

Step 18: Retail Display & Consumer Use

Vodka is displayed in retail stores in shelf-stable spirits sections, not requiring refrigeration (though many consumers prefer chilled vodka for drinking).

Shelf-life is indefinite—vodka purchased today will be identical to vodka purchased 10 years ago if stored properly.

Most vodka is consumed in mixed drinks (martinis, cosmopolitans, vodka tonics) rather than neat.

Why This Process?

Fermentation converts carbohydrates into alcohol—the active ingredient that creates intoxication and shelf stability.

Distillation concentrates alcohol while removing water and heavy impurities—the result is 80-95% ABV spirit far stronger than fermented liquid (15-18%).

Charcoal filtration removes congeners (flavor and odor compounds) that create hangovers and unpleasant tastes—this is what makes vodka distinctly neutral.

Multiple distillations progressively remove more impurities, resulting in smoother spirit—though the differences are subtle above 3 distillations.

Vodka Quality & Variations

Vodka quality is determined by multiple factors:

• Raw material: Grain (wheat, rye, barley) vs. potatoes—grain produces higher yields but potatoes claim to produce smoother vodka (unproven)

• Distillation: More distillations = higher purity, smoother taste, higher cost

• Filtration: Charcoal only vs. multiple filtration stages

• Water quality: Mineral content of dilution water affects final mouthfeel

• Production scale: Industrial (large volume, consistent quality) vs. craft (small batch, variable quality)

Many vodka brands are functionally identical—all distilled to 95%+ purity, all charcoal-filtered, all diluted to 40% ABV. Price differences often reflect branding, packaging, and marketing rather than actual quality differences.

The Bottom Line

Vodka production is a straightforward fermentation and distillation process optimized for purity and neutrality—converting carbohydrate sources into alcohol through fermentation, then aggressively purifying that alcohol through distillation and filtration to remove all flavor compounds.

The result is a nearly flavorless spirit intentionally designed to be a blank canvas for mixed drinks.

Now you understand exactly how grains or potatoes become vodka through fermentation, distillation, and purification—a process optimizing for neutrality rather than character.