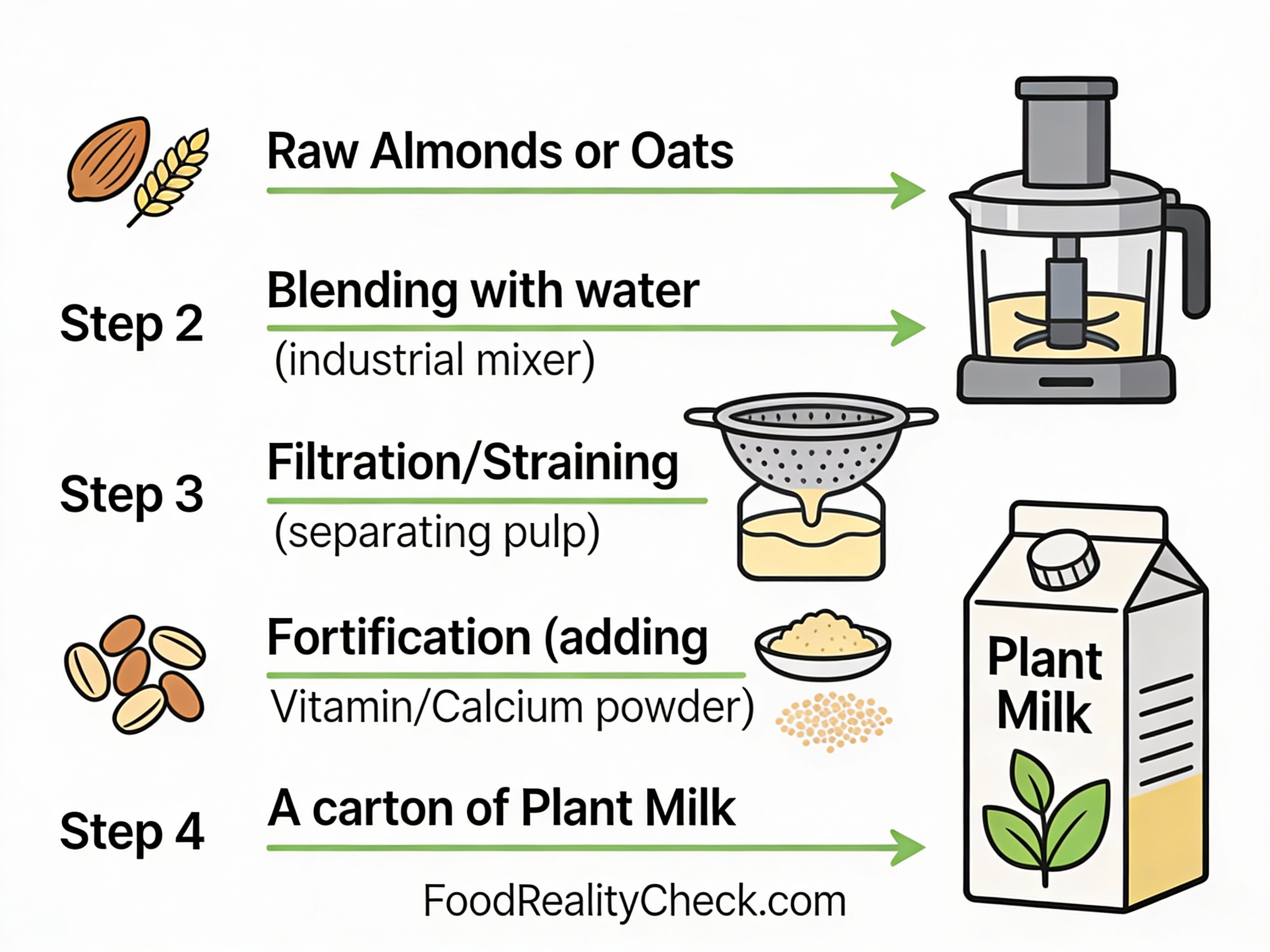

From almonds, oats, and soybeans to your carton.

The Overview

Plant-based milk is a rapidly growing alternative to dairy milk, made by extracting and processing nuts, grains, legumes, or seeds.

The process involves soaking, grinding, extraction, and industrial refinement to create a creamy beverage with extended shelf-life.

Here’s exactly what happens at each stage, from raw ingredients to finished product.

🥘 Base Ingredients (Varies by Type)

• Almonds (for almond milk)

• Oats (for oat milk)

• Soybeans (for soy milk)

• Coconut (for coconut milk)

• Rice, peas, and other grains/legumes

Step 1: Ingredient Selection & Cleaning

Raw materials arrive at the factory in bulk and are sorted using optical scanning technology that inspects each nut or grain in milliseconds.

Debris, broken pieces, stones, and contaminants are removed automatically.

For almonds and most nuts, pasteurization using steam is applied to kill bacteria before processing begins.

Step 2: Pre-Treatment (Dehulling, Cracking, Rolling)

Different ingredients require different prep: almonds may be blanched to remove skins; oats are dehulled to remove tough outer husks and lightly heat-treated to stabilize enzymes.

Soybeans are cleaned, cracked, dehulled, and rolled into flakes to maximize extraction efficiency.

This step is critical for flavor and texture development in the final milk.

Step 3: Soaking

The prepared ingredients are soaked in water for 8-12 hours (for nuts and legumes) to hydrate them fully.

This softens the plant material, removes antinutrients like phytic acid and trypsin inhibitors, and improves digestibility.

Soaking also begins to release flavors and nutrients from the raw material.

Step 4: Grinding & Wet Milling

Soaked almonds, oats, or soybeans are transferred to heavy-duty industrial grinders that create a thick, gritty slurry.

Think of this as a massive industrial smoothie—plant solids are completely pulverized into fine particles suspended in liquid.

This creates maximum surface area for the next extraction step.

Step 5: Extraction & Filtration (The Heart of the Process)

The slurry is pumped into industrial-scale extraction systems where the liquid plant milk is separated from solid residue.

For almond milk, this works like a giant French press—the mixture is pressed through fine mesh screens under pressure.

For soy milk, decanter centrifuges spinning at up to 5,000 RPM separate the liquid from solids. The result is a base milk liquid rich in proteins, fats, and nutrients.

Refinement: Creating Commercial Consistency

Step 6: Emulsification & Homogenization

Raw plant milk naturally separates—fats float to the top, water sinks to the bottom, just like oil and vinegar.

To prevent this, emulsifiers like lecithin (from soy or sunflower) or mono- and diglycerides are added at controlled temperatures above 140°F (60°C).

A high-shear homogenizer forces the mixture through tiny valves at extreme pressure, breaking down fat molecules into microscopic droplets that stay evenly suspended.

Step 7: Stabilization & Thickening

Hydrocolloids (thickening agents) like xanthan gum, guar gum, or locust bean gum are added to create a creamy mouthfeel and prevent separation during storage.

These natural gums also improve texture and shelf stability without adding calories.

Calcium and vitamin D are often fortified at this stage to match dairy milk’s nutritional profile.

Step 8: Pasteurization & Heat Treatment

The plant milk is flash-heated to approximately 185°F (85°C) for 15-30 seconds to kill bacteria and ensure food safety.

This heat treatment extends shelf-life significantly, allowing the product to sit on store shelves for weeks without refrigeration.

Some products undergo ultra-high temperature (UHT) processing for even longer shelf stability.

Step 9: Final Formulation & Flavoring

Additional ingredients are mixed in: sweeteners (sugar or stevia), vanilla extract, cocoa (for chocolate varieties), or salt for flavor balance.

The pH is adjusted to prevent spoilage and improve taste.

The finished product is stirred to ensure uniform consistency and ingredient distribution.

Step 10: Aseptic Packaging

The pasteurized plant milk is cooled and filled into sterile cartons or containers in a completely sealed, oxygen-free environment.

Aseptic technology ensures zero contamination and allows shelf-stable products to be stored at room temperature for 6+ months.

The product is then distributed to retailers worldwide.

Why This Process?

The multi-step extraction and refinement process creates a product that mimics dairy milk’s creamy texture and shelf stability.

Emulsification and stabilizers prevent the natural separation that would occur if you simply blended nuts with water at home.

Heat treatment ensures food safety and extends shelf-life by years compared to fresh alternatives.

What About Additives?

Most commercial plant-based milks include:

• Emulsifiers (lecithin, mono- and diglycerides) – to prevent separation

• Stabilizers (xanthan gum, guar gum) – for creamy texture

• Vitamins & minerals (calcium, vitamin D, B12) – for nutritional fortification

• Sweeteners (sugar, stevia) – for taste

• Preservatives – to extend shelf-life

Clean-label brands may use fewer additives but risk separation and shorter shelf-life.

The ingredient list typically reveals the quality and simplicity of the product.

The Bottom Line

Plant-based milk production is a sophisticated industrial process that transforms simple plant materials into shelf-stable beverages.

It relies on extraction, emulsification, stabilization, and heat treatment to replicate the sensory and practical qualities of dairy milk.

Now you understand exactly why your plant-based milk looks and tastes consistent across every bottle.