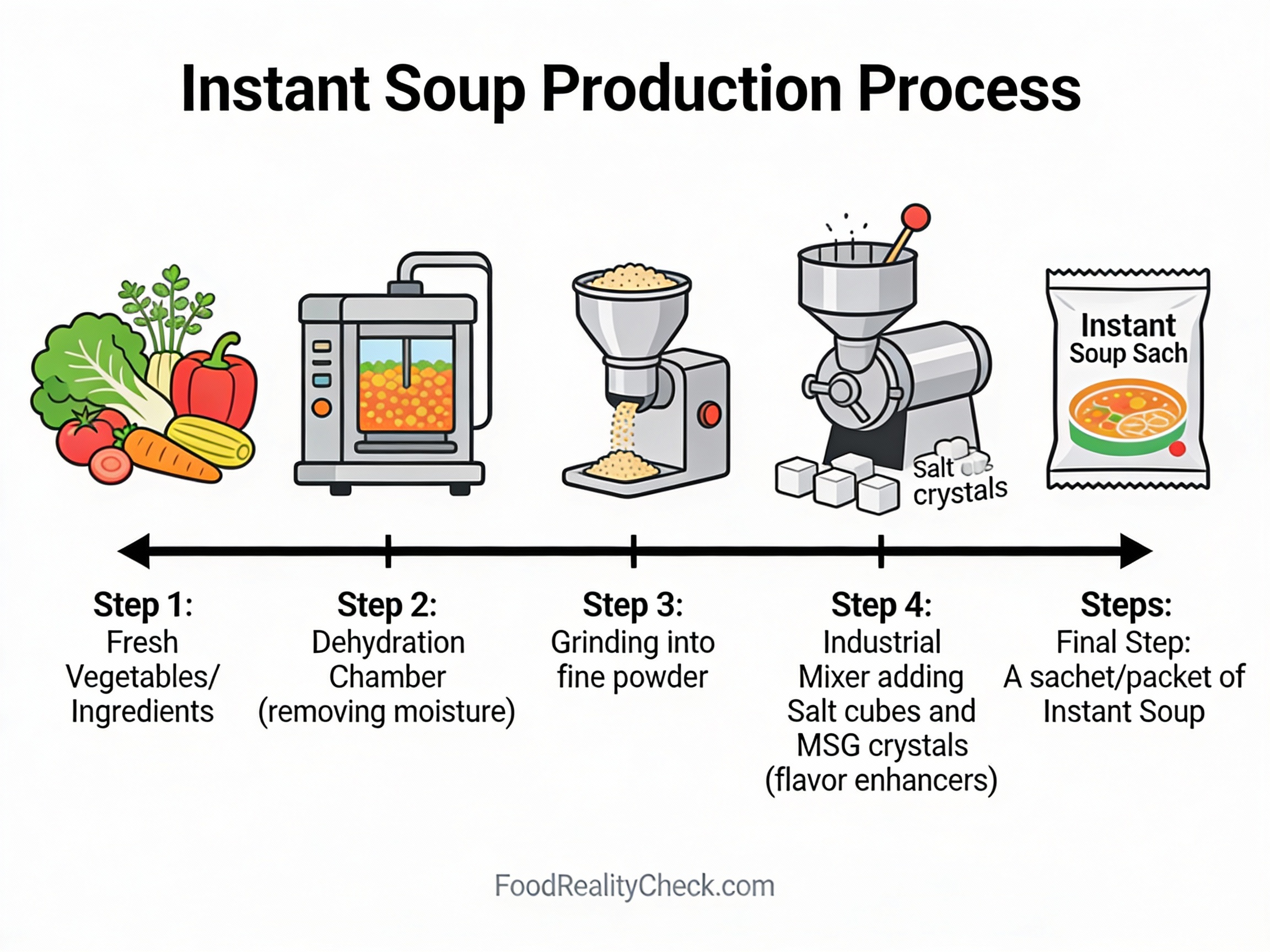

How Are Instant Soups Made?

From fresh ingredients to dehydrated powder through cooking, drying, and precise ingredient blending.

The Overview

Instant soups are made by cooking soup components (vegetables, meat, noodles, pasta), dehydrating them through spray-drying or freeze-drying to remove water, and blending the dried ingredients with seasonings, thickeners, and flavorings into a convenient powder that reconstitutes with hot water.

The manufacturing process transforms fresh soup into shelf-stable, convenient portions through industrial cooking, moisture removal, and precise ingredient portioning—enabling consumers to prepare soup in minutes by simply adding hot water, instead of simmering fresh ingredients for 30+ minutes.

Here’s exactly how fresh soup becomes instant powder through dehydration and industrial food processing.

🥘 Main Ingredients & Components

• Dried vegetables (carrots, peas, celery, onions)

• Dried pasta or noodles (ramen, egg noodles)

• Dehydrated meat or seafood (optional)

• Starch-based thickeners (corn starch, potato starch)

• Seasonings (salt, garlic, pepper, herbs)

• Flavor enhancers (MSG, yeast extract)

• Oil (for palatability and mouthfeel)

• Preservatives (optional)

Step 1: Ingredient Sourcing & Pre-Processing

Individual ingredients arrive at the instant soup factory from suppliers: fresh vegetables (carrots, celery, peas), dried pasta or noodles, meat/seafood (if included), and pre-measured spice blends and seasonings.

Fresh vegetables are washed, trimmed, and pre-cut into small pieces (1-10mm depending on desired final texture).

Pasta and noodles are typically sourced pre-made from specialist manufacturers, requiring no additional cooking before incorporation into the soup mix.

Step 2: Vegetable Cooking & Flavor Development

Fresh vegetables are cooked in large industrial kettles or steam-jacketed vats at 90-100°C for 10-30 minutes to soften them and develop flavor through heat-driven chemical reactions (Maillard reaction creating browning).

Cooking also inactivates enzymes that would cause discoloration and flavor degradation during storage.

The vegetable cooking liquid (broth) is often reserved and later used to rehydrate dried vegetables for better flavor, or discarded if it’s too dilute.

Step 3: Cooling & Preparation for Drying

Cooked vegetables are cooled to 20-30°C on conveyor belts or in cooling tanks before being transferred to dehydration equipment.

While vegetables cool, meat components (if included) are separately cooked, cooled, and optionally shredded or diced to appropriate size.

All components must be cooled before drying—hot vegetables would burn or overcook during the dehydration process.

💡 Did You Know? Instant ramen noodles are technically pre-cooked (par-fried or steamed) before being dried, which is why they rehydrate so quickly with hot water. Fresh pasta would require 5-10 minutes of boiling; instant noodles only need 3-4 minutes because they’re partially cooked during manufacturing. This pre-cooking step is what makes “instant” soups actually instant.

Dehydration: The Critical Drying Phase

Step 4: Spray-Drying (Most Common Method)

For liquid components (soup broth, oils, seasonings dissolved in water), spray-drying is the primary dehydration method. Liquid is sprayed into a hot chamber (150-200°C) where water instantly evaporates, leaving behind solid particles.

The spray-dried particles are extremely fine (10-100 microns), powder-like, and rehydrate instantly when mixed with hot water.

Spray-drying is incredibly fast—the entire drying process takes seconds, preserving flavor and nutrition better than slow drying methods.

Step 5: Freeze-Drying (Premium Option for Vegetables)

For premium instant soups, vegetables are freeze-dried instead of spray-dried—a more expensive but superior method.

Freeze-drying works by freezing vegetables to -30°C, then placing them in a vacuum chamber where ice sublimes directly into water vapor without melting, leaving behind a porous, lightweight structure.

Freeze-dried vegetables rehydrate better than spray-dried (softer, more vegetable-like texture) and retain more nutrients, but the process is 5-10x more expensive and slower.

Step 6: Hot Air Drying (Budget Method)

For budget instant soups, hot air drying in large chambers is used—vegetables are spread on conveyor belts and exposed to 70-100°C hot air for 30 minutes to several hours.

This slower drying method is cheaper but produces lower quality results: longer drying time damages delicate vegetables, creating tough, chewy texture and nutrient loss.

Hot air-dried vegetables don’t rehydrate as well as spray-dried or freeze-dried, resulting in grainier, less appealing final texture.

Step 7: Collection of Dried Solids

Dried vegetables, meat, and other solids fall through collection chutes where they’re gathered and temporarily stored in bins or containers.

All dried components are cooled to room temperature before being weighed and portioned for final mixing.

Moisture content is verified using moisture analyzers—proper drying ensures 3-8% residual water, preventing microbial growth while maintaining rehydration ability.

Seasoning, Blending & Portioning

Step 8: Seasoning & Flavor Enhancement Preparation

Pre-measured salt, spices (garlic powder, pepper, herbs), and flavor enhancers (MSG, yeast extract, bonito extract) are combined in blending tanks.

Some liquid components (oils, flavor concentrates) may be mixed with powdered ingredients (starch, salt) to create a uniform dry blend before adding to the dried vegetables.

Precise ingredient ratios are critical—every batch must taste identical to previous batches.

Step 9: Ingredient Blending & Mixing

Dried vegetables, dehydrated noodles, dried meat (if included), seasonings, and thickening agents are combined in large industrial mixers (ribbon blenders or paddle mixers) at low speed for 3-5 minutes.

Low-speed mixing ensures even distribution without crushing delicate dried vegetables.

The final dry mixture should be visually uniform—no clumps of salt, no visible seasoning powder streaks.

Step 10: Portioning Into Packets or Containers

Blended instant soup mixture is divided into individual portions using automated portioning equipment at 100-500 portions per minute depending on package size.

Typical portions are 25-50 grams (enough for 1 cup/250ml soup when reconstituted with hot water).

Weight control is precise—modern equipment maintains ±0.5 gram accuracy, ensuring every packet contains the exact target weight.

Step 11: Packaging (Sachets or Rigid Containers)

Portioned soup mixture is filled into heat-sealable sachets (small plastic pouches) or rigid plastic/foam cups depending on product format.

For sachet packaging, the mixture is sealed using heat sealers that bond the plastic layers together, creating an airtight barrier.

For cup-in-cup format (soup sold in a styrofoam cup with soup powder inside), the mixture is pre-loaded into the cup before the cup is sealed with a lid.

Step 12: Labeling & Printing

Sealed packets or cups are labeled with brand name, flavor, cooking instructions (typical: “Add hot water, stir, wait 3 minutes”), nutrition facts, ingredients list, and allergen warnings.

Batch codes and “best by” dates are printed for traceability (typically 18-24 months from manufacturing).

For cup-format soups, labels are pre-printed on the cup itself during cup manufacturing; sachets receive adhesive labels during packing.

Step 13: Case Packing & Cartooning

Labeled packets or cups are packed into larger boxes (typically 4-12 individual portions per box) which are then stacked and packed into shipping cases (40-60 boxes per case).

Boxes are sealed and labeled with batch codes, product description, and handling instructions.

Cases are stacked on pallets for storage and distribution.

Step 14: Quality Control & Shelf Stability Testing

Representative samples from each production batch are retained for quality testing: reconstitution test (add water, verify texture and flavor), moisture analysis, microbial testing, and shelf-life verification.

Shelf-life testing involves storing samples at elevated temperatures (40°C) and checking for flavor degradation, texture changes, or mold growth over time.

Only batches passing all tests are released for distribution.

Step 15: Storage & Distribution

Quality-approved instant soups are stored in climate-controlled warehouses at 15-25°C with 40-50% humidity—dry conditions that prevent moisture absorption and preserve crispness.

Packets are distributed via ambient temperature trucks to retailers, vending machines, and food service establishments.

In stores, instant soups are displayed in shelf-stable sections (no refrigeration required) with typical shelf-life of 18-24 months from manufacturing.

Why This Process?

Dehydration removes 90-95% of water from fresh soup, preventing bacterial and mold growth while reducing weight/volume by 95%—enabling convenient storage and transport.

Spray-drying or freeze-drying preserves flavor compounds that would degrade during slow drying—the quick moisture removal minimizes flavor loss.

Pre-cooked vegetables and noodles rehydrate quickly with hot water, enabling true “instant” preparation (3-5 minutes) instead of 20-30 minutes for fresh ingredients.

Precise portioning ensures consistency—every packet tastes identical, helping consumers trust the product quality.

What About Quality & Additives?

Instant soups typically contain:

• Corn starch or modified starches – for thickening and texture

• Salt (1-2% by weight) – for preservation and taste

• Flavor enhancers (MSG, yeast extract) – for umami/savory depth

• Vegetable oil powder – for mouthfeel and energy

• Preservatives (typically none needed due to low moisture)

• Colorants (rarely, for visual appeal)

• Spice extracts – for concentrated flavor

Premium instant soups use freeze-dried vegetables (expensive), minimal additives, and premium ingredients.

Budget instant soups use hot-air-dried vegetables (cheaper), more starch fillers, and more flavor enhancers to compensate for quality loss.

The Bottom Line

Instant soup production is an industrial food preservation process that transforms fresh soup into convenient, shelf-stable powder through cooking, dehydration, and precise ingredient blending.

The key innovation—dehydration (spray, freeze, or hot-air drying)—removes water that would cause spoilage, enabling 18+ month shelf stability without refrigeration.

Now you understand exactly how fresh vegetables and meat transform into instant powder through dehydration technology and modern food processing.