How Is Barbecue Sauce Made?

From tomatoes and spices to smoky, tangy condiment through cooking and careful blending.

The Overview

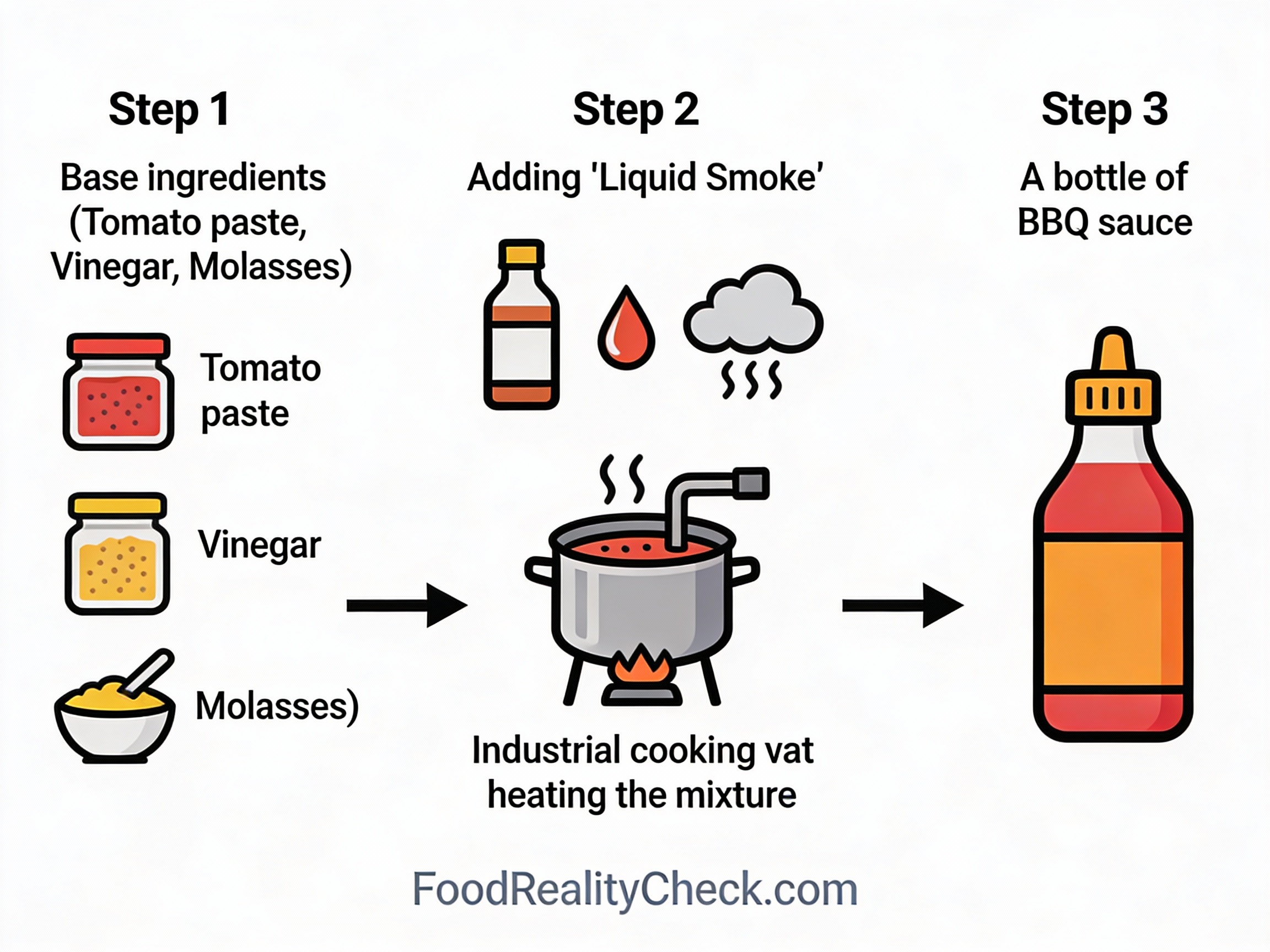

Barbecue sauce is a complex condiment combining tomato-based components (ketchup or tomato puree), vinegar, sugar (brown sugar or molasses), spices, and optional smoke flavoring through multi-stage cooking, blending, and pasteurization.

The manufacturing process transforms raw ingredients into a thick, flavorful sauce through controlled heating, precise ingredient proportion, homogenization for texture consistency, and thermal processing to extend shelf-life while preserving the distinctive smoky-sweet-tangy flavor profile.

Here’s exactly what happens from raw ingredients to the finished sauce in your bottle.

🥘 Main Ingredients

• Ketchup or tomato puree (tomato base)

• Vinegar (apple cider or white vinegar)

• Brown sugar or molasses (sweetness and depth)

• Spices (paprika, chili powder, mustard powder, garlic powder, onion powder)

• Worcestershire sauce (savory depth)

• Liquid smoke (optional, for smoky flavor)

• Salt and pepper

Step 1: Ingredient Sourcing & Preparation

Individual ingredients arrive at the manufacturing facility from suppliers: ketchup (or fresh tomatoes if making puree from scratch), vinegar, brown sugar, molasses, and pre-measured spice blends.

Each ingredient is tested for quality, batch consistency, and absence of contaminants before being released to production.

Ingredients are stored in controlled conditions—ketchup and vinegar in stainless steel tanks, sugar in climate-controlled bins, and spices in sealed containers away from light and heat.

Step 2: Ingredient Measurement & Dosing

The base ketchup or tomato puree is pumped into large stainless steel mixing tanks (1,000-5,000+ gallons capacity) using automated measurement systems.

Precise volumes are dispensed—modern facilities use flow meters and weight sensors to measure each ingredient to within ±1% accuracy.

Brown sugar, molasses, vinegar, and spices are added in the exact ratios calculated by the food scientist who formulated the sauce recipe.

Step 3: Gentle Blending at Controlled Temperature

The measured ingredients are mixed using low-speed paddle mixers or gentle circulation systems at 21-24°C (70-75°F) for 20-30 minutes.

Temperature control is critical—if the sauce heats above 30°C during initial blending, spice volatile compounds evaporate, reducing final flavor intensity.

The blending process ensures complete hydration of powdered spices and even distribution of all ingredients before heating begins.

Step 4: Cooking & Flavor Development

Once fully blended, the sauce is heated in large steam-jacketed kettles to 82°C (180°F) for 30-45 minutes while continuous stirring prevents scorching and ensures uniform heating.

This controlled cooking allows sugar and molasses to fully dissolve and meld with tomato and spices, developing the complex flavors that characterize barbecue sauce.

The Maillard reaction during cooking creates additional browning compounds and savory depth—this chemistry is essential for authentic barbecue sauce flavor.

Step 5: Liquid Smoke Addition (Optional)

For smoked varieties, liquid smoke is added near the end of cooking (during the last 5-10 minutes of the heating phase) in carefully measured amounts.

Liquid smoke is pure smoke flavor distilled from actual wood smoke—just a few percent by volume dramatically increases the smoky character.

Timing is critical—adding liquid smoke too early allows the volatile smoke compounds to evaporate; too late and it doesn’t integrate with other flavors.

Processing: Cooling, Homogenization & Quality Control

Step 6: Rapid Cooling Phase

After cooking is complete, the hot sauce is transferred to cooling systems where it’s gradually cooled from 82°C back to 20-25°C over 30-60 minutes.

Rapid cooling is avoided—quick temperature drops can cause separation of ingredients or create undesirable texture changes.

During cooling, the sauce viscosity increases as sugars and fats solidify, reaching the final thickness consumers expect.

Step 7: Homogenization (Texture Fine-Tuning)

Cooled sauce passes through industrial homogenizers or colloid mills operating at high shear forces to reduce particle size and create uniform texture.

Homogenization breaks down any remaining chunks of spice or sugar crystals, creating a smooth, velvety mouthfeel with no graininess.

Multiple passes through the homogenizer may be required to achieve the target viscosity and texture consistency.

Step 8: Quality Control Laboratory Testing

Before any sauce proceeds to packaging, samples are tested for color (spectrophotometer), viscosity (using standardized flow measurements), pH (acidity), taste (trained sensory panels), and texture consistency.

Advanced equipment like gas chromatographs analyze volatile flavor compounds to ensure every batch matches the standard formula.

Batches failing any specification are diverted—they’re either reformulated to meet standards or discarded if beyond salvage.

Step 9: Pasteurization (Heat Treatment for Shelf-Life)

Tested sauce is pumped through a heat exchanger where it’s rapidly heated to 85°C (185°F) for 15-30 seconds to eliminate bacteria and extend shelf-life.

This brief pasteurization kills spoilage organisms and pathogens while the short heating time preserves flavor and color.

For ultra-shelf-stable products, more aggressive heat treatment (90-95°C for 30+ seconds) may be used, at the cost of slightly muted flavor.

Step 10: Rapid Re-cooling Post-Pasteurization

Immediately after pasteurization, the sauce is cooled back to 65-75°C in a second heat exchanger section to prevent flavor loss from prolonged heating.

This entire heating-cooling cycle takes only 1-2 minutes, preserving maximum flavor while ensuring food safety.

The sauce now has extended shelf-life (typically 12-24 months unopened at room temperature) while maintaining authentic taste.

Bottling, Packaging & Distribution

Step 11: Filling into Bottles

Pasteurized sauce at 65-75°C is pumped to automated high-speed filling machines operating at 80-120 bottles per minute with precision fill control.

Fill volumes are measured to precise weights—typically 18oz (510g), 28oz (793g), or 40oz (1,134g) jars—with accuracy better than ±1%.

Bottles are filled from the bottom via nozzles that prevent excessive foaming or air incorporation during filling.

Step 12: Capping & Hot-Water Bath Sterilization

Immediately after filling, hot bottles (65-75°C) are conveyed to automated capping machines that apply lids at precise torque.

Some premium producers submerge hot-filled bottles in boiling water baths for 2-5 minutes—the residual heat inside the bottle creates steam that sterilizes the headspace and improves seal integrity.

This water-bath pasteurization ensures the bottle headspace (air above the sauce) is also sterilized, extending shelf-life even further.

Step 13: Cooling & Label Application

Hot bottles are cooled in air tunnels or water spray systems to room temperature (20-25°C) over 15-30 minutes.

Cooled bottles move to labeling machines that apply front and back labels, nutrition facts panels, ingredients lists, barcode, and manufacturing information.

Batch codes and expiration dates are printed using thermal transfer or laser marking systems for traceability and recall capability.

Step 14: Case Packing & Storage

Labeled bottles are robotically packed into cardboard cases (typically 6-12 bottles per case depending on bottle size) and placed on plastic pallets.

Cases are wrapped with plastic film for shipping stability and loaded into climate-controlled warehouses or onto trucks for distribution.

Properly sealed and pasteurized barbecue sauce remains shelf-stable at room temperature for 12-24 months, or indefinitely if frozen.

Step 15: Retail Distribution & Consumer Use

Packaged barbecue sauce is distributed via refrigerated or ambient trucks to retail stores, restaurants, and food service establishments.

In stores, sauce is displayed in shelf-stable sections (not necessarily refrigerated, though some consumers prefer refrigeration after opening).

Consumers purchase and use within the printed “best by” date, with typical shelf-life of 1-2 years from manufacturing.

Why This Process?

Controlled heating develops complex flavors through the Maillard reaction—browning reactions between amino acids and sugars that create savory depth.

Gentle initial blending at room temperature preserves delicate spice aromas that would evaporate if heated too early.

Homogenization creates smooth texture while breaking down ingredient particles to uniform microscopic size.

Brief pasteurization (85°C for 15-30 seconds) extends shelf-life while the short heating time preserves maximum flavor compared to extended heating.

What About Variations & Additives?

Barbecue sauce varieties vary dramatically by region:

• Kansas City style: Thick, sweet, tomato-based with molasses

• Carolina style: Thin, vinegar-forward, minimal tomato

• Texas style: Spicy, smoky, meat-forward

• Memphis style: Thin, sweet, with mustard balance

Commercial barbecue sauces typically contain:

• High fructose corn syrup (cheaper sweetener than sugar)

• Modified starches or gums – for texture stability

• Preservatives (potassium sorbate) – extend shelf-life further

• Natural or artificial smoke flavoring

• Caramel color – for consistent brown color

Premium artisanal barbecue sauces may contain only tomatoes, vinegar, brown sugar, molasses, spices, and salt—nothing more.

The Bottom Line

Barbecue sauce production is a carefully controlled cooking and blending process that transforms simple ingredients—ketchup, vinegar, sugar, spices—into a complex, multi-layered condiment.

The key innovations—controlled temperature cooking, homogenization for texture, and brief pasteurization—maximize flavor development while ensuring food safety and extended shelf-life.

Now you understand exactly how tomatoes, vinegar, and spices combine into barbecue sauce through careful cooking, precise blending, and modern food processing technology.