From grain to glass through ancient chemistry.

The Overview

Beer production relies on just four ingredients: water, malted grains, hops, and yeast.

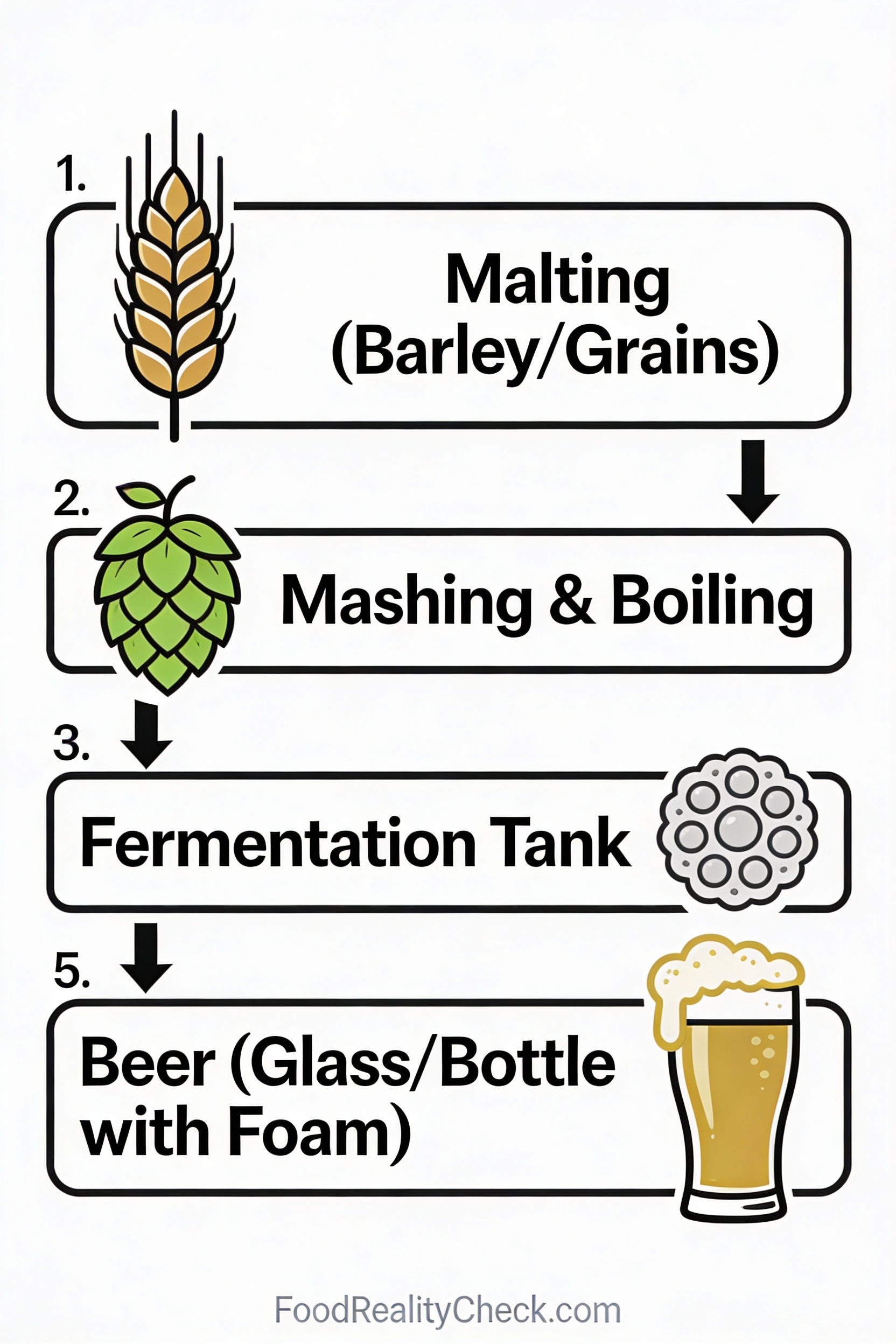

The brewing process transforms these simple materials into a complex beverage through malting, mashing, fermentation, and carbonation.

Here’s exactly what happens at each stage.

🥘 Main Ingredients

• Water

• Malted barley (or wheat, rye)

• Hops

• Yeast

Step 1: Malting the Grain

Barley grains are soaked in cold water (12-15°C) for 2-3 days to activate them.

Grains are then allowed to germinate for 4-6 days, developing enzymes that will later convert starches into fermentable sugars.

Finally, the sprouted grain is dried in a kiln at controlled temperatures (50-80°C), stopping germination and developing flavor and color.

Step 2: Mashing (Extracting the Sugars)

Malted grain is mixed with hot water (65-70°C) in a process called mashing.

Natural enzymes in the malt break down starches into fermentable sugars over 1-2 hours at controlled temperatures.

The resulting sweet liquid is called wort and contains the sugars that yeast will consume.

Step 3: Lautering & Sparging

The liquid wort is slowly drawn from the bottom of the mash vessel through the grain bed, which acts as a natural filter.

Hot water is sprayed over the grain (sparging) to extract all remaining sugars from the spent grains.

This results in a clear, sugar-rich wort ready for boiling.

Step 4: Boiling & Hop Additions

Wort is boiled for 60-90 minutes, sterilizing it and concentrating flavors.

Different hop varieties are added at different times: early additions provide bitterness, mid-boil additions add flavor, and late additions provide aroma.

Bittering compounds (alpha acids) from hops balance the sweetness of malt and preserve the beer.

Step 5: Cooling & Aeration

After boiling, wort is rapidly cooled to 15-25°C using a heat exchanger or ice bath.

The cooled wort is aerated to introduce oxygen, which yeast needs to reproduce and ferment effectively.

The wort is transferred to fermentation vessels, and any remaining solid particles (trub) settle out.

The Fermentation Heart: Where Beer Becomes Beer

Step 6: Pitching the Yeast & Fermentation

Yeast is added (pitched) into the cooled wort, beginning the primary fermentation.

Yeast consumes the sugars and produces three byproducts: ethanol (alcohol), carbon dioxide (carbonation), and flavor compounds (esters).

Ale yeast ferments at 16-22°C and rises to the top; lager yeast ferments at 9-16°C and sinks to the bottom.

Step 7: Active Fermentation Phase

During the first 24-72 hours, yeast rapidly multiplies and produces a visible foam layer called krausen.

The beer smells strongly of fermentation—this is where complex flavor compounds develop.

The sealed fermenter builds pressure from CO2 production, naturally carbonating the beer as fermentation proceeds.

Step 8: Conditioning & Settling

After 5-14 days (depending on yeast type and temperature), fermentation slows and enters the stationary phase.

Yeast begins to settle to the bottom, clarifying the beer and reducing harsh flavors.

Undesirable compounds like hydrogen sulfide escape as gas, and the beer develops a smoother, more balanced taste.

Step 9: Filtering & Bright Tanking

The beer is slowly transferred to another tank (a bright beer tank), leaving yeast sediment behind.

Fine filtration removes remaining solids, proteins, and haze, creating the clear appearance expected in most commercial beers.

This tank is the final holding station before bottling or kegging.

Carbonation: The Final Bubble

Step 10: Carbonation Methods

Most commercial breweries use two carbonation methods: natural fermentation produces some CO2, but most is stripped out during filtration and then re-injected.

The beer is chilled to 0-4°C (yeast becomes inactive; cold liquid absorbs CO2 more readily).

CO2 is injected at 15-20 PSI (pounds per square inch) pressure, forcing gas into solution until the desired carbonation level is reached.

Step 11: Bottling & Kegging

Carbonated beer is filled into bottles, cans, or kegs under pressure to prevent CO2 loss.

For bottle conditioning, a small amount of yeast and sugar may be added to create secondary fermentation in the bottle—producing natural carbonation.

Beer is typically held in cold storage (0-4°C) until distribution to consumers.

Why This Process?

The multi-step brewing process develops complex flavors through controlled fermentation and chemical reactions.

Temperature control during mashing activates different enzymes, producing desired sugar profiles and proteins that create foam.

Fermentation temperature and yeast selection determine the final flavor profile—ales are fruity and accessible, lagers are crisp and clean.

What About Additives?

Most commercial beers are made with just the four base ingredients: water, malt, hops, and yeast.

Some breweries add:

• Finings (gelatin or isinglass) – to clarify the beer

• Preservatives – to extend shelf-life

• Adjunct grains (corn, rice) – to lighten body and reduce costs

Premium craft beers and most imports contain only water, malt, hops, and yeast.

Check the label for a complete ingredient list.

The Bottom Line

Beer brewing is an ancient yet scientifically precise process that transforms grain, water, hops, and yeast into a complex beverage.

It relies on temperature control, fermentation chemistry, and careful timing to develop flavor and preserve the product.

Now you understand exactly how beer goes from brewing vessel to your glass.