The Overview

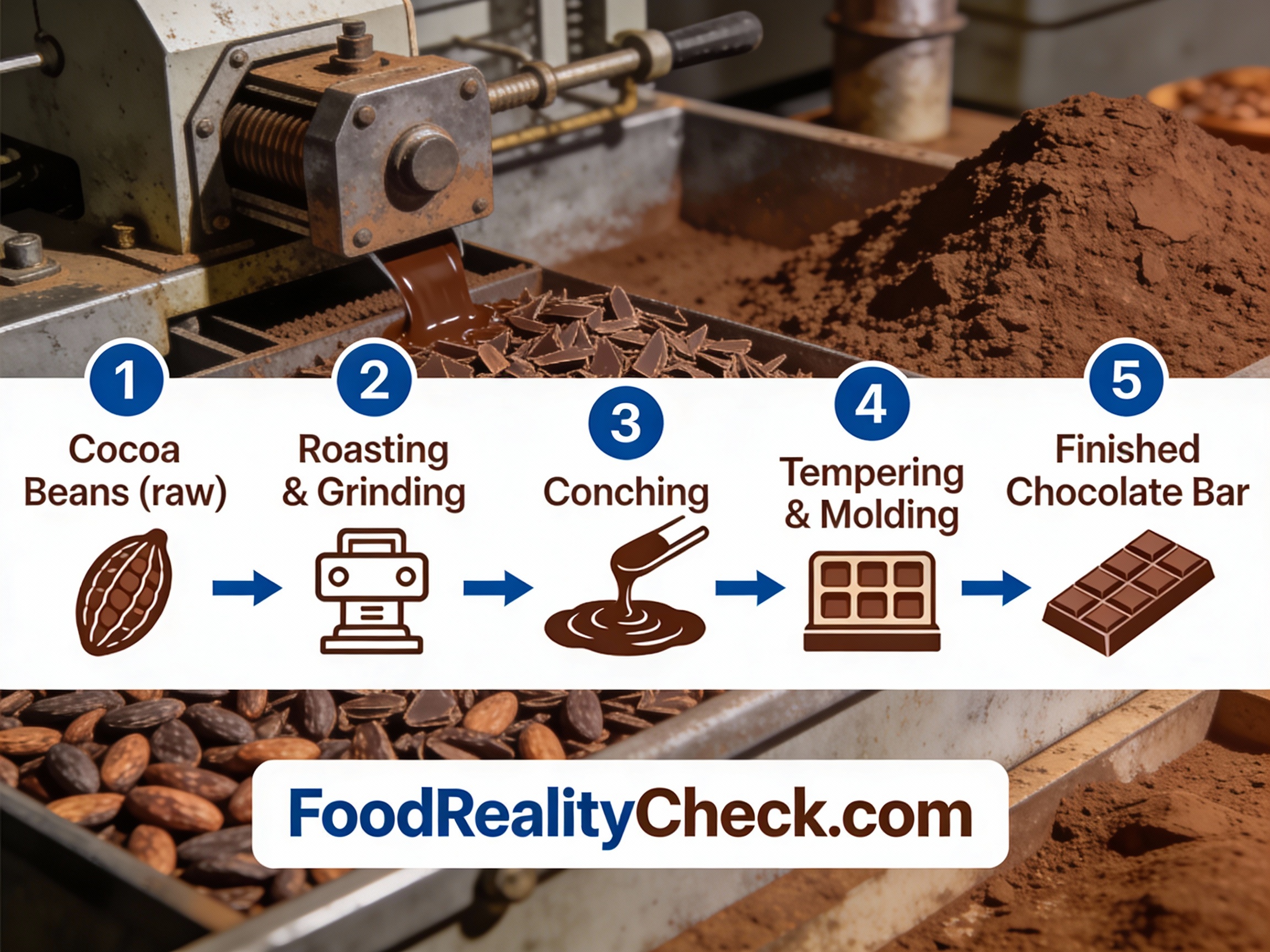

Most chocolate comes from factories processing cacao beans.

The process involves fermentation, roasting, grinding, and tempering.

Here’s exactly what happens step by step.

🥘 Main Ingredients

• Cacao beans

• Cocoa butter

• Sugar

• Milk powder (for milk chocolate)

Step 1: Harvesting Cacao Pods

Cacao pods are hand-harvested from Theobroma cacao trees when ripe.

Beans and white pulp are removed from the pods.

This takes place twice yearly.

Step 2: Fermentation

Beans ferment in boxes or heaps for 5-8 days developing flavor.

Microbes break down pulp sugars, killing germs.

Temperature reaches up to 55°C inside.

Step 3: Drying the Beans

Fermented beans dry in sun for 7-14 days on mats.

Beans are turned regularly to remove moisture evenly.

This is where flavor precursors stabilize.

Step 4: Roasting & Winnowing

Beans roast at 120-140°C to develop chocolate aroma.

Shells removed by winnowing, leaving cocoa nibs.

Roasting kills bacteria like Salmonella.

Step 5: Grinding & Conching

Nibs ground into cocoa liquor releasing cocoa butter.

Mixture conched for hours/days with sugar and milk for smoothness.

This ensures velvety texture and flavor development.

Why This Process?

Modern chocolate production uses these steps for consistent flavor.

It develops complex aromas through Maillard reactions.

And it keeps costs controlled through efficient scaling.

What About Additives?

Most commercial chocolate includes:

• Lecithin – for better flow and texture

• Vanilla – for aroma

• Emulsifiers – for smooth mixing

These aren’t secrets.

They’re listed on the label.

The Bottom Line

Chocolate production is methodical.

It’s designed for flavor optimization.

Now you know exactly what happens.