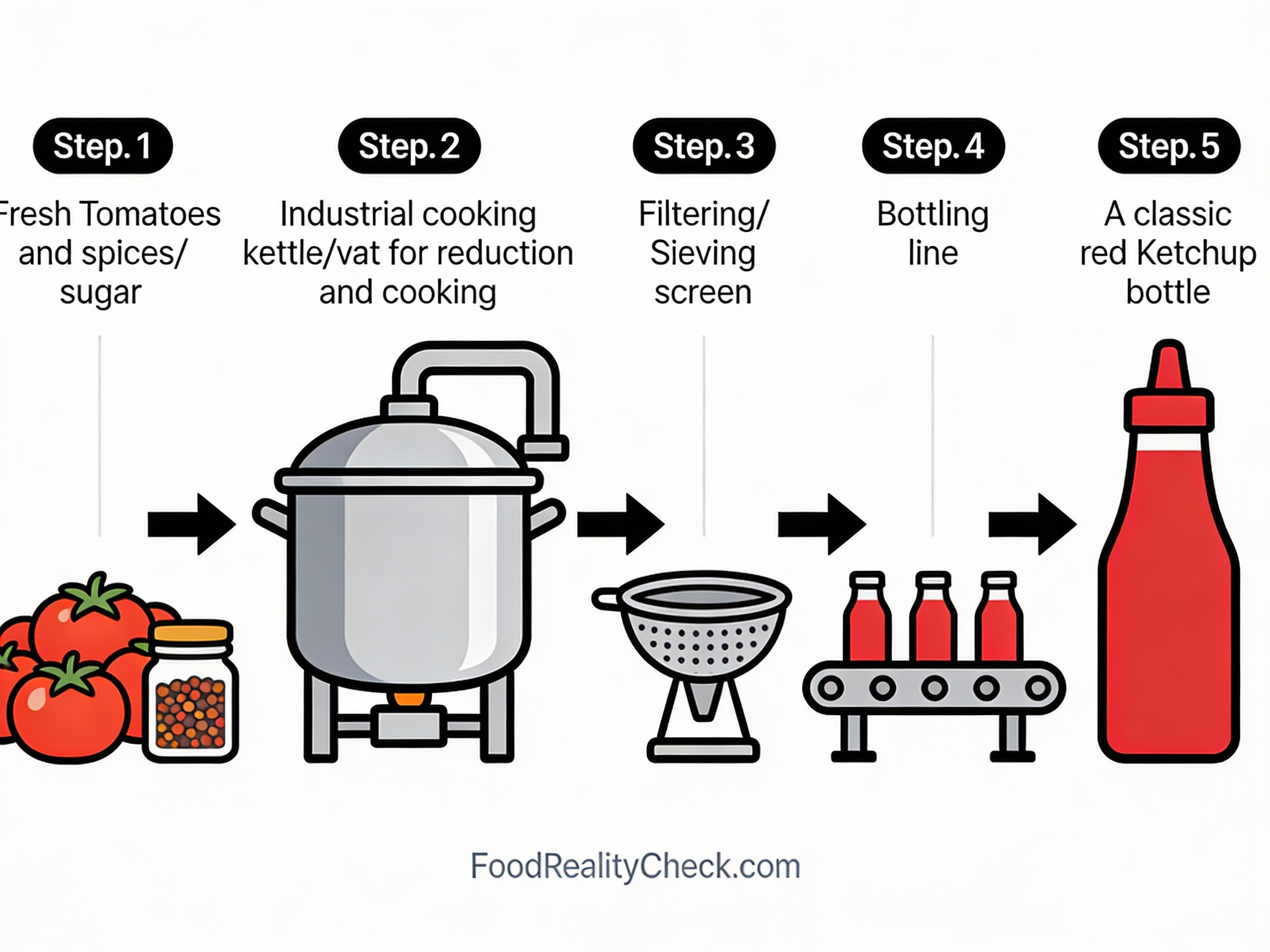

How Is Ketchup Made?

From fresh tomatoes to bottled condiment perfection.

The Overview

Ketchup is a tomato-based condiment created by blending tomato paste with vinegar, sugar, spices, and salt through a carefully controlled cooking and mixing process.

The manufacturing process combines ingredient preparation, high-heat cooking, homogenization, and pasteurization to create a shelf-stable product with consistent texture and flavor.

Here’s exactly what happens from harvest to the finished bottle on store shelves.

🥘 Main Ingredients

• Tomato paste or concentrated tomato pulp

• Vinegar (distilled white or apple cider)

• Sugar

• Salt

• Spices (onion powder, garlic powder, mustard powder, cinnamon, cloves)

• Water

Step 1: Tomato Harvesting & Transport

Fresh tomatoes arrive at the factory in large trucks immediately after harvest during peak season (July-September in North America).

Tomatoes are unloaded into receiving pits where they’re conveyed directly to processing equipment, often on the same day they were picked.

This rapid transfer preserves quality and prevents deterioration, ensuring fresh flavor in the finished ketchup.

Step 2: Washing & Sorting

Tomatoes pass through industrial washing machines that spray them with water while rotating drums or conveyor belts remove dirt, leaves, stems, and other debris.

Optical sorters inspect each tomato for color, size, and quality, automatically rejecting underripe, overripe, or damaged fruit.

Only premium quality tomatoes proceed to the next stage—rejected fruit is composted or used for animal feed.

Step 3: Crushing & Pre-Cooking

Sorted tomatoes are fed into large industrial crushers or pulpers that break them into a coarse pulp, separating liquid from fibrous material.

The crushed tomatoes are immediately transferred to steam-jacketed kettles where they’re heated to 80-90°C (176-194°F) for 30-45 minutes.

This “Hot Break” method preserves natural pectin (a thickening agent found in tomatoes) while softening the pulp and inactivating spoilage enzymes.

Step 4: Pulping & Seed Removal

The cooked tomato mixture passes through cyclone separators or rotary drum filters that remove seeds, skins, and fibrous material.

This creates a smooth tomato juice or pulp with the solids content desired for the final product—typically 12-15% solids by weight.

By-products (seeds, skins) are separated and often used for animal feed or composting.

Step 5: Concentration (Evaporation)

The filtered tomato juice moves to vacuum evaporators that remove excess water, concentrating the tomato solids into a thick paste.

Vacuum evaporation operates at reduced pressure (below atmospheric), allowing evaporation at lower temperatures (typically 60-70°C), which preserves color and flavor better than atmospheric evaporation.

The tomato concentrate is reduced from roughly 5% solids to 25-30% solids—a five-fold concentration of flavor and nutrients.

Mixing & Cooking: The Heart of Ketchup

Step 6: Ingredient Preparation & Precise Dosing

In the next phase, the concentrated tomato paste is transferred to large mixing tanks equipped with automated ingredient dispensers.

Sugar, vinegar, salt, and powdered spices are measured and added in exact quantities using precision dosing systems—maintaining consistency across millions of bottles.

Water is added to dilute the concentrate to the final desired solids content and viscosity.

Step 7: High-Shear Mixing

A high-shear mixer with a rotating rotor and stationary stator blends the ingredients at intense speeds, creating powerful suction that draws all materials into the mixing workhead.

This violent mixing ensures complete hydration of powdered ingredients, even dispersion of spices, and uniform flavor throughout the batch.

The circulatory pattern forces materials through the shear zone multiple times, breaking up agglomerates and creating a perfectly homogeneous blend.

Step 8: Cooking in Large Kettles

The mixed ketchup is transferred to large steam-jacketed cooking kettles where the entire batch is heated to 85-95°C (185-203°F) for 15-30 minutes.

This second cooking step ensures thorough blending of flavors, inactivates any remaining enzymes or microorganisms, and allows flavors to meld and develop.

Temperature is carefully controlled—too high and bitterness develops; too low and flavor doesn’t fully develop.

Step 9: Finishing & Fiber Removal

The cooked ketchup passes through fine-mesh finishing machines (strainers with holes 0.5-1.0mm) that remove remaining fibers and particles.

This ensures the ultra-smooth texture consumers expect—no graininess or visible particles even under magnification.

Some commercial producers adjust viscosity by adding small amounts of modified starches or gums if needed to achieve the target thickness.

Step 10: Homogenization (Under Extreme Pressure)

The finished ketchup is forced through a high-pressure homogenizer operating at 15,000+ PSI (pounds per square inch)—pressure equivalent to the deepest point of the ocean.

This extreme pressure breaks down any remaining particle agglomerates and emulsifies the mixture, creating a perfectly smooth mouthfeel with no separation.

Homogenization also prevents layers of ingredients from separating during storage, ensuring consistency throughout shelf life.

Pasteurization, De-Aeration & Packaging

Step 11: De-Aeration

Before pasteurization, the ketchup passes through a de-aeration chamber that removes dissolved air and oxygen using vacuum or steam injection.

Removing oxygen prevents oxidation (which causes darkening and flavor changes), inhibits bacterial growth, and helps preserve color and freshness throughout the 12+ month shelf life.

De-aerated ketchup stays bright red and tastes fresh far longer than aerated product.

Step 12: Pasteurization & Heat Exchange

De-aerated ketchup is rapidly heated to 85-88°C (185-190°F) using a plate heat exchanger—a device with alternating hot and cold plates that efficiently transfers heat.

This temperature and 5-15 minute holding time kill pathogenic bacteria (E. coli, Salmonella) and most spoilage microorganisms, making the product safe for consumption.

Pasteurization is critical to shelf stability—without it, ketchup would spoil in weeks; with it, the product remains shelf-stable for 12+ months at room temperature.

Step 13: Rapid Cooling

Immediately after pasteurization, the hot ketchup is cooled to 65-70°C using a second heat exchanger where cool water circulates on the opposite side of the plates.

Rapid cooling prevents overcooking that would darken color and develop off-flavors, while preparing the product for filling into cool containers.

The entire heating and cooling process takes only minutes—from 20°C to 85°C and back to 70°C in rapid succession.

Step 14: Quality Control Checks

Before packaging, every batch is tested for color, viscosity, acidity (pH), and taste by quality control experts.

Viscosity is measured using standardized equipment—flow through a narrow opening is timed, ensuring consistency across batches.

Off-spec batches (wrong color, viscosity, or taste) are reformulated or rejected entirely, ensuring only perfect ketchup is packaged.

Step 15: Hot Filling & Sealing

The cooled ketchup (now approximately 70°C) is filled into pre-sterilized glass bottles or plastic containers using automated high-speed filling machines.

Machines dispense precise volumes—typically 567g (20oz) or 946ml (32oz)—at 300-500 bottles per minute.

Immediately after filling, caps are applied and tightened by automated capping machines, creating an airtight seal that prevents contamination and leakage.

Step 16: Cooling & Labeling

Hot-filled bottles are conveyed through cool air tunnels or cold water sprays, rapidly cooling to room temperature in 30-60 minutes.

Cooled bottles move to labeling machines that apply nutrition labels, ingredient lists, expiration dates, and barcodes at high speed.

Final inspection removes any bottles with damaged labels, caps, or defects before they reach packaging lines.

Step 17: Carton Packing & Distribution

Labeled bottles are robotically packed into cardboard cases (typically 12-24 bottles per case) and stacked on pallets for shipment.

Cases are labeled with batch codes, manufacturing dates, and distribution information, then stored in climate-controlled warehouses.

Finished ketchup is distributed to retailers worldwide through refrigerated or ambient distribution networks depending on local requirements.

Why This Process?

Multiple heating steps (pre-cooking at harvest, cooking during mixing, and pasteurization) ensure food safety and develop complex flavors through the Maillard reaction and caramelization of sugars.

Homogenization under extreme pressure creates a perfectly smooth, stable product with no separation or settling during 12+ months of storage.

De-aeration prevents oxidation and microbial growth, extending shelf life dramatically and preserving bright red color and fresh taste.

What About Additives?

Most commercial ketchups contain:

• Corn syrup or high fructose corn syrup – for sweetness and body

• Modified corn starch or xanthan gum – for consistency

• Spice extracts – for intense flavor

• Citric acid – for tanginess and preservation

• Natural flavors – for depth

Premium ketchups use only real tomatoes, vinegar, sugar, and spices with minimal additives.

Some artisanal brands skip thickeners entirely, relying on the natural pectin from carefully handled tomatoes.

The Bottom Line

Ketchup production is a sophisticated process that combines tomato processing, ingredient mixing, multi-stage cooking, homogenization, and pasteurization.

It’s designed to create a shelf-stable product with consistent flavor, color, and texture that remains fresh for over a year without refrigeration.

Now you understand exactly how fresh tomatoes transform into the iconic condiment through careful thermal management, precision mixing, and rigorous quality control.