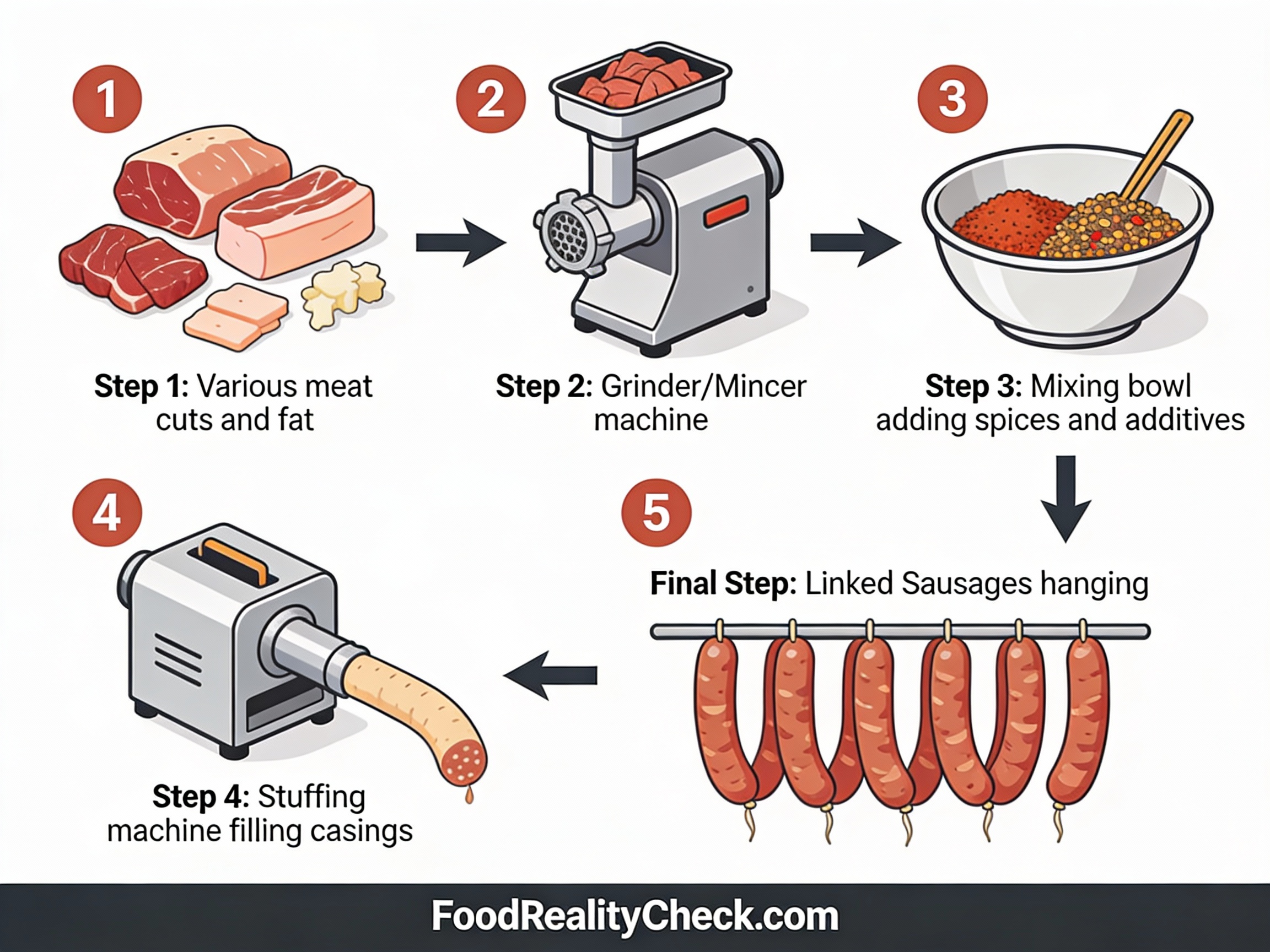

How Is Sausage Made?

From raw meat to seasoned links through grinding, mixing, stuffing, and cooking or curing.

The Overview

Sausage is made by grinding raw meat (pork, beef, poultry) into fine particles, mixing it with fat, seasonings (salt, spices, herbs), binders (rusk, soy protein), and optional curing agents, forcing the mixture into casings (natural or artificial), and either cooking fresh sausage immediately or curing and smoking for shelf-stable varieties.

The manufacturing process transforms tough meat cuts and fat into a uniform, flavorful product through grinding, precise seasoning, and either cooking or curing—enabling producers to use inexpensive meat trimmings and create premium products through skillful seasoning and processing.

Here’s exactly how raw meat becomes the sausages you find in grocery stores through grinding, mixing, stuffing, and cooking or curing.

🥘 Main Ingredients

• Raw meat (pork, beef, lamb, poultry, or combinations)

• Fat (pork fat, beef fat, or vegetable shortening)

• Salt (curing agent and preservative)

• Spices (garlic, pepper, paprika, fennel, oregano, etc.)

• Binders (breadcrumbs/rusk, soy protein, or gelatin)

• Curing agents (sodium nitrite, for cured varieties)

• Natural or artificial casings

• Water or ice (to prevent overheating during grinding)

Step 1: Meat Selection & Grinding Preparation

Raw meat (typically pork shoulder, pork butt, beef chuck, or poultry) arrives at the sausage factory from meat suppliers.

Meat is inspected for quality, trimmed of excessive bone and gristle, and cut into chunks suitable for grinding (typically 2-4 inch cubes).

Both meat and grinding equipment are kept very cold (0-4°C) to prevent the meat from warming up during grinding—heat causes fat to melt and creates poor texture.

Step 2: Grinding (Breaking Down Meat Structure)

Chilled meat chunks are fed into large industrial meat grinders where sharp rotating blades and a die with specific hole sizes break the meat into uniform fine particles.

Grind size varies by sausage type: finer grinds (3-5mm) create smoother texture; coarser grinds (8-12mm) create chunkier, more rustic sausage.

Temperature control is critical—the grinder can generate friction heat that warms the meat to 15-20°C, ruining texture. Ice is sometimes added to the meat before grinding to keep it cold.

Step 3: Fat Selection & Addition

Ground meat alone would be dry and unpalatable—fat is essential for flavor, moisture, and texture.

Typical sausage contains 20-30% fat by weight. Fat is typically pork back fat (from the pig’s back), beef fat, or vegetable shortening.

Fat is ground separately (in cold conditions) and measured precisely—ratios determine final texture and mouthfeel.

💡 Did You Know? Sausage casing (outer skin) is traditionally made from animal intestines—pig intestines for fresh sausage (casings stretch to about 3.5cm diameter), beef intestines for larger sausages. The intestinal membrane is cleaned and salted, then used to stuff meat mixture. Modern artificial casings (cellulose or collagen) are also widely used—they’re consistent, don’t require special handling, and make production more efficient.

Step 4: Seasoning & Binding Mixture Preparation

Spices (salt, pepper, garlic, paprika, fennel, oregano, or proprietary spice blends) are measured precisely according to recipe specifications.

Binders (rusk—dried ground bread, soy protein, or gelatin) are added at 2-5% by weight to absorb and retain water during cooking, improving texture.

For cured sausages, curing agents (sodium nitrite at 150-200 ppm) are added to prevent botulism and create characteristic pink color.

Water or ice is sometimes added (at 5-15% by weight) to help bind ingredients and improve texture.

Step 5: Mixing (Emulsification & Protein Extraction)

Ground meat, ground fat, seasonings, binders, and water are combined in large industrial mixers operating at medium-low speed for 3-10 minutes.

Mixing serves two critical purposes: (1) even distribution of seasonings and fat throughout the meat, and (2) extraction of myosin proteins that act as natural binders, helping hold the sausage together during cooking.

Mixing is carefully controlled—overmixing develops gluten-like proteins that make sausage tough and paste-like; undermixing leaves unmixed pockets of fat and seasoning.

Step 6: Stuffing into Casings

The seasoned meat mixture is forced into casings using a stuffer machine—a piston press that pushes the mixture into casing strands at high pressure.

Modern stuffers can fill 50-200+ sausages per minute, maintaining consistent pressure and casing diameter throughout the process.

Casings are typically 20-30cm long (allowing for tying or linking later), and filled to consistent diameter and firmness.

Step 7: Linking (Dividing into Individual Sausages)

Stuffed casings are divided into individual sausages by tying or twisting at regular intervals (typically every 10-15cm).

Traditional methods use string for tying; modern operations use twisting machines that pinch the casing at predetermined points, creating natural separations.

Each linked sausage is typically 80-150 grams depending on desired size.

Cooking or Curing: Creating Final Product

Step 8a: Fresh Sausage (For Immediate Cooking)

Fresh sausages (breakfast sausage, bratwurst, Italian sausage) are cooled after stuffing and either packaged immediately for refrigerated sale or cooked before packaging.

These sausages contain no curing agents, so they must be refrigerated and consumed within 3-7 days.

Consumers cook fresh sausages at home using pan-frying, grilling, or baking.

Step 8b: Cooked Sausage (Pre-Cooked for Convenience)

Some sausages (hot dogs, kielbasa) are partially or fully cooked before packaging, allowing consumers to reheat rather than cook from raw.

Cooking is accomplished in hot water (80-85°C) for 15-30 minutes (for full cooking) or shorter duration for partial cooking.

Cooked sausages are cooled in ice water to stop cooking and set the texture, then packaged in vacuum-sealed casings.

Step 9: Curing & Smoking (For Shelf-Stable Varieties)

For cured sausages (pepperoni, salami, prosciutto-wrapped sausages), the freshly stuffed sausages are transferred to a drying chamber where they’re hung at controlled temperature (12-18°C) and humidity (75-85%).

During curing, salt penetrates the meat, water evaporates, and the curing agent (sodium nitrite) develops characteristic pink color and prevents botulism.

Curing duration varies: fresh-style sausages may cure only 24-48 hours; traditional cured varieties (pepperoni) cure 20-30+ days.

Step 10: Smoking (Optional, for Smoked Varieties)

For smoked sausages, cured sausages are transferred to smoke chambers where they’re exposed to smoke from hardwood (hickory, oak, apple) for 1-8 hours depending on desired smoke intensity.

Smoke develops flavor compounds and provides additional preservation through antimicrobial smoke components.

Temperature during smoking is carefully controlled (50-80°C depending on desired cooking level) to prevent fat rendering or overcooking.

Step 11: Cooling & Drying Completion

After curing and/or smoking, sausages are cooled in climate-controlled rooms at 15-20°C to room temperature.

For cured sausages, cooling is slow and controlled—rapid cooling can cause moisture imbalances that degrade texture.

Final drying may continue for days to weeks for traditional varieties, as more water evaporates and flavors concentrate.

Step 12: Packaging

Cooled sausages are packaged in vacuum-sealed casings (plastic shrink wrap or modified atmosphere packages) that remove oxygen and preserve freshness.

Some sausages are individually wrapped; others are packed multiple per package.

Vacuum sealing or nitrogen flushing extends shelf-life: fresh sausages 3-7 days refrigerated, cooked sausages 2-3 weeks refrigerated, cured sausages 2-6 months refrigerated or longer frozen.

Step 13: Labeling & Quality Control

Packaged sausages are labeled with product type (fresh, cooked, cured), ingredients, nutrition facts, cooking instructions, and allergen warnings.

Quality control includes visual inspection (color, size consistency), weight verification, and microbiological testing (for cooked and cured varieties, ensuring safety).

Batches failing specifications are diverted or discarded.

Step 14: Storage & Distribution

Fresh and cooked sausages are stored in refrigeration (0-4°C); cured sausages can be stored at room temperature (for long-term) or refrigerated.

Distribution is via refrigerated trucks for fresh and cooked varieties, ambient trucks for shelf-stable cured varieties.

Retail display is in refrigerated meat sections for fresh and cooked varieties, shelf-stable sections for cured varieties.

Why This Process?

Grinding breaks down tough muscle fibers, creating tender, uniform texture impossible with whole meat.

Fat addition creates moisture and flavor—pure lean meat sausage is tough and dry.

Mixing extracts myosin proteins that act as natural binders, holding the sausage together during cooking.

Salt extraction of myosin proteins creates the characteristic sausage texture—firm but succulent, not mushy like ground meat.

Curing with sodium nitrite prevents botulism while creating characteristic pink color and extending shelf-life.

Sausage Types & Variations

Sausage diversity is enormous, determined by meat type, spice blends, and processing:

• Fresh sausage: No curing, refrigerate and cook—bratwurst, Italian, breakfast

• Cooked sausage: Pre-cooked, reheat or eat cold—kielbasa, hot dogs, summer sausage

• Cured sausage: Dried and cured, ready-to-eat—pepperoni, salami, prosciutto

• Smoked sausage: Cured then smoked—andouille, chorizo (some styles)

• Specialty: Regional varieties with unique spice profiles—Chinese, Thai, Middle Eastern, Scandinavian styles

Meat composition varies dramatically—pork (most common), beef, poultry, game (venison, wild boar), and mixed varieties create distinct flavors and textures.

The Bottom Line

Sausage production is a straightforward grinding and mixing process that transforms inexpensive meat trimmings and fat into premium products through skillful seasoning, mixing, and either cooking or curing.

The key innovations—precise grinding, myosin extraction through salt, and curing—transform humble ingredients into flavorful, shelf-stable products.

Now you understand exactly how raw meat becomes sausage through grinding, mixing, stuffing, and cooking or curing—a process combining ancient preservation techniques with modern food technology.