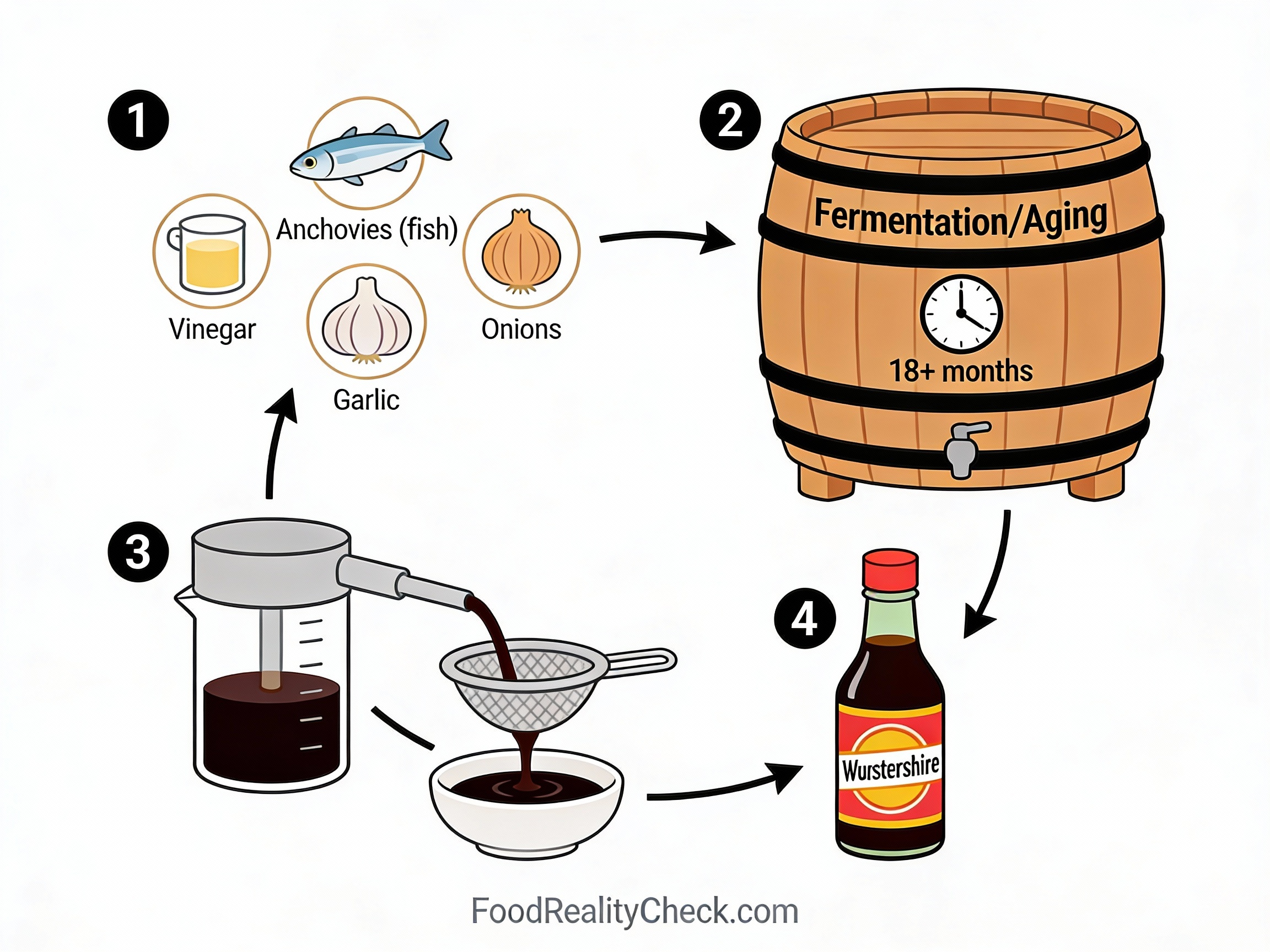

How Is Worcestershire Sauce Made?

From anchovies to umami through months of fermentation and careful blending.

The Overview

Worcestershire sauce is a complex condiment produced through the fermentation and extended aging of anchovies, vinegar, molasses, tamarind, and spices in wooden barrels or large tanks for 6 months to 2 years.

The manufacturing process is defined by patience—the longer the fermentation, the more complex and balanced the final flavor. Traditional producers like Lea & Perrins have used nearly identical methods since the 1830s, combining ancient fermentation techniques with modern pasteurization and bottling to create the iconic condiment.

Here’s exactly how simple ingredients transform into the distinctive tangy-savory-sweet sauce through extended fermentation and careful blending.

🥘 Main Ingredients

• Anchovies (salt-cured, aged in barrels)

• Vinegar (malt, spirit, or white vinegar)

• Molasses (dark brown sugar syrup)

• Tamarind paste (tropical fruit concentrate)

• Onions & garlic (aged separately)

• Spices (clove, chili, mustard, cinnamon)

• Salt

• Sugar

Step 1: Ingredient Sourcing & Pre-Fermentation

Anchovies are sourced from Spain and other fishing regions, salt-cured to remove moisture, and shipped to the sauce factory where they’re stored in barrels or tanks with salt.

For premium producers like Lea & Perrins, anchovies age in large wooden casks (200+ kg batches) for approximately 2 years before being mixed with other ingredients.

Meanwhile, whole red onions and garlic cloves are pickled separately in malt vinegar and salt brine for 9-18 months in the factory basement—this pre-fermentation develops complex flavors before the final sauce is assembled.

Step 2: Individual Ingredient Preparation

Tamarind paste is prepared from the tropical fruit, extracting its concentrated tart flavor.

Molasses (thick, dark brown syrup from sugar refining) is measured and prepared.

Spices—clove, chili, mustard seed, cinnamon, mace—are weighed into precise quantities according to the closely-guarded secret recipe.

Vinegar is selected (malt vinegar in UK versions, spirit or white vinegar in American versions) and measured.

Step 3: Initial Mixing in Large Tanks

Pre-aged anchovies, fermented onions, and fermented garlic are combined in massive mixing tanks (5,000+ liters capacity) with vinegar, molasses, tamarind paste, spices, and salt.

The mixture is blended thoroughly at controlled temperature (20-25°C) to ensure complete hydration and even distribution of all ingredients.

At this stage, the sauce is extremely pungent and intense—overpowering to taste directly.

Step 4: Primary Fermentation & Aging (Months to Years)

The blended mixture is transferred to huge fermentation tanks (30,000+ liter capacity) or traditional wooden casks where it rests for a minimum of 6 weeks to 18+ months depending on the desired final product.

During fermentation, complex enzymatic reactions occur: proteins break down into amino acids (creating umami), starches convert into sugars, and harsh compounds mellow through oxidation and bacterial metabolism.

Premium traditional producers age their sauce in wooden casks for the full 18 months to 2 years, while some commercial producers use shorter fermentation (6 weeks to 6 months) with added flavorings to accelerate flavor development.

Step 5: Regular Stirring & Monitoring

During fermentation, the sauce is stirred regularly (traditionally by hand, now often by automated mechanical stirrers) to ensure even flavor development and prevent stratification.

Batches are sampled regularly and tested for acidity (pH), color, and flavor balance—any batch deviating from specifications is adjusted by blending with other batches or adding additional ingredients.

The fermentation vessel must be sealed but vented periodically to allow gases from fermentation to escape without allowing oxygen infiltration that would cause oxidation.

Final Processing: Blending, Pasteurization & Bottling

Step 6: Blending & Flavor Adjustment

Once primary fermentation is complete, batches from different fermentation vessels are combined in large blending tanks.

Master blenders (trained flavor experts) taste the sauce and make adjustments: adding vinegar if too sweet, molasses if too acidic, or additional spices if flavor lacks depth.

This blending and adjustment phase ensures consistency across millions of bottles—every bottle tastes identical to the original formula.

Step 7: Water Dilution (Final Viscosity)

The concentrated fermented sauce is too intense and thick for table use. Filtered water (or the specific vinegar used) is added to dilute the sauce to the target viscosity and intensity.

Modern manufacturers use precise flow meters to add water at controlled rates, achieving the characteristic pourable consistency that consumers expect.

At this stage, the sauce is now balanced: tangy from vinegar, savory from anchovies, sweet from molasses, and complex from months of fermentation.

Step 8: Clarification & Filtration

The blended sauce is filtered through fine mesh screens or membrane filters to remove suspended solids and clarify the liquid.

Some producers use centrifuges to accelerate solids removal, while others use settling tanks where heavy particles naturally fall out of suspension.

The result is a clear, uniform sauce ready for pasteurization and bottling.

Step 9: Pasteurization (Heat Treatment)

Clarified sauce is pumped through a heat exchanger where it’s rapidly heated to 85-90°C (185-194°F) for 15-30 seconds to kill residual bacteria and extend shelf-life.

This brief pasteurization is critical—extended heating would destroy the delicate flavors developed during fermentation.

Immediately after heating, the sauce is cooled back to 65-70°C to stop the pasteurization process and prevent flavor loss.

Step 10: Rapid Cooling Post-Pasteurization

The sauce is quickly cooled to room temperature (20-25°C) in a second heat exchanger section to stabilize flavors and prepare for bottling.

The entire heating-cooling cycle takes only 1-2 minutes, preserving the complex fermented flavors while ensuring food safety and extended shelf-life.

Pasteurized sauce can now be stored at room temperature unopened for several years.

Step 11: Filling into Bottles

Pasteurized sauce at room temperature is pumped to high-speed automated filling machines operating at 300+ bottles per minute with precision fill control.

Fill volumes are measured to exact amounts—typically 150ml, 300ml, or 600ml bottles—with accuracy better than ±1%.

Bottles are filled from the top using precision nozzles that prevent foaming or aeration of the sauce.

Step 12: Capping & Sealing

Immediately after filling, bottles are conveyed to automated capping machines that apply screw caps at precise torque (tightness).

Caps must be tight enough to maintain a seal during storage and transport, but not so tight that consumers cannot easily open them.

Each sealed bottle is checked for proper sealing—any defective bottles are automatically rejected and discarded.

Step 13: Labeling & Quality Verification

Sealed bottles move to labeling machines that apply the iconic label, ingredients list, nutrition facts, barcode, and manufacturer information at high speed.

Batch codes and “best by” dates are printed using thermal transfer or laser marking for traceability and recall capability if needed.

Vision inspection systems verify label placement, legibility, and proper sealing before bottles leave the production line.

Step 14: Case Packing & Storage

Labeled bottles are robotically packed into cardboard cases (typically 12-24 bottles per case) and stacked on pallets.

Cases are wrapped with plastic film and stored in climate-controlled warehouses at room temperature or cool conditions.

Properly sealed and pasteurized Worcestershire sauce remains shelf-stable at room temperature for 3-5 years, longer if refrigerated.

Step 15: Distribution & Retail Display

Packaged sauce is distributed via ambient or refrigerated trucks to retailers, restaurants, and food service establishments worldwide.

In stores, sauce is displayed in shelf-stable condiment sections at room temperature (not requiring refrigeration).

Consumers purchase and use within the printed date range, with the sauce remaining fresh for years if properly stored.

Why This Process?

Extended fermentation breaks down proteins into amino acids and creates inosinate—the umami compound that makes the sauce distinctively savory.

Wooden cask aging (traditional method) allows slow oxidation and flavor maturation impossible in stainless steel tanks, creating the complex, rounded flavor profile.

Pre-fermentation of anchovies, onions, and garlic separately develops their individual flavors before final blending, creating layers of taste rather than a flat, one-dimensional sauce.

Brief pasteurization (85-90°C for 15-30 seconds) extends shelf-life while the short heating time preserves delicate fermented flavors that would be destroyed by longer heat exposure.

What About Additives?

Traditional Worcestershire sauce (particularly Lea & Perrins UK version) contains only:

• Vinegar (malt)

• Molasses

• Anchovies

• Tamarind

• Onions

• Garlic

• Spices

• Salt

• Water

American versions may include high-fructose corn syrup instead of molasses for cost reduction.

Vegan versions substitute mushrooms or seaweed for anchovies, replacing the umami source.

All versions lack artificial preservatives—fermentation and pasteurization provide natural preservation.

The Bottom Line

Worcestershire sauce production is fundamentally a fermentation and aging process that transforms simple ingredients—anchovies, vinegar, molasses—into a complex, multi-layered condiment.

The patience required—months to years of fermentation—is what distinguishes authentic Worcestershire sauce from quick imitations.

Now you understand exactly how anchovies and fermentation create the iconic umami-rich sauce through extended aging, careful blending, and modern pasteurization.