Lab-grown (cultivated) meat is produced by culturing animal cells in bioreactors—creating actual meat without raising/slaughtering animals. Understanding safety testing, regulatory approval, and fundamental differences from beef reveals that cultivated meat is literally animal cells, not synthetic or plant-based.

What Is Cultivated Meat

Cultivated meat is actual animal muscle tissue grown from animal cells in bioreactors (large tanks with controlled conditions). Key point: It’s literally meat—animal muscle cells—not synthetic, not plant-based, not processed. Process: Animal cells are extracted, cultured in growth medium, organized into muscle tissue structure, resulting in product chemically identical to slaughtered meat.

The fundamental question is not “is it safe” but “is it different from conventional meat”—the answer is: biochemically, not substantially.

Production Basics

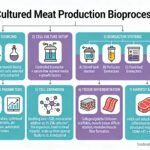

Overview: (1) Animal muscle biopsy provides starter cells. (2) Cells are cultured in growth medium (nutrients, growth factors). (3) Culture expands from thousands to billions of cells. (4) Cells are organized into tissue structure (often using scaffolds). (5) Final product is harvested, processed into meat form. (6) Result: raw meat product ready for cooking.

The process is essentially tissue engineering—same techniques used in medical regenerative medicine.

Cell Source Material

Cell source: Live muscle biopsy from living animal (approximately 5-10mm sample, painless). Important: One biopsy provides cells for essentially unlimited cultivation—no animal slaughter required. Cell type: Usually muscle satellite cells (muscle stem cells) that differentiate into mature muscle fibers. Genetic identity: Cultivated meat contains the exact same genetic material as conventional meat from that animal.

Cultivated meat is literally the animal’s own cells—genetically identical to slaughtered meat.

Safety & Regulatory Approval

Safety testing (precommer): (1) Cell viability testing (ensuring cells are healthy). (2) Contamination screening (bacteria, viruses, fungi). (3) Compositional analysis (protein, fat, nutrients match beef). (4) Toxicology testing (no harmful compounds). (5) Allergenicity assessment. Regulatory approval: Singapore (2020) approved first cultivated meat product. United States reviewing applications (FDA process ongoing, 2024+).

Cultivated meat has undergone regulatory review—initial data shows safety equivalent to conventional meat.

Biochemical Identity to Beef

Composition analysis: Cultivated beef contains proteins, fats, micronutrients essentially identical to conventional beef. Amino acid profile: Identical (same cells produce same proteins). Fat composition: Similar (though may be slightly different depending on growth medium composition). Micronutrients: Iron, zinc, B vitamins present at similar levels.

From a biochemical perspective, cultivated meat is indistinguishable from conventional meat—same cells, same composition.

Commercial Status

Current (2026): Limited commercial availability (Singapore approved, other countries pending). Price: Significantly higher than conventional meat (technology still expensive). Market trajectory: Expected cost reductions as scale increases. Consumer acceptance: Mixed—some enthusiastic (environmental benefits), some hesitant (“lab meat” perception).

Cultivated meat is early-stage technology—not yet mainstream, but regulatory approval is progressing.

Realistic Safety Assessment

Safety equivalent to beef: Cultivated meat contains beef cells—biologically, it is beef. No synthetic compounds, no unnatural processes. Regulatory scrutiny: Actually undergoes more testing than conventional meat (regulatory requirement). Potential advantages: No antibiotics, no hormones (controlled environment), potentially lower pathogenic contamination risk.

Honest assessment: Cultivated meat is safe—it’s literally animal muscle cells. Safety concerns are overstated; concerns should focus on environmental/economic viability rather than food safety.