A comprehensive guide to the revolutionary biotechnology transforming food production.

What Is Precision Fermentation?

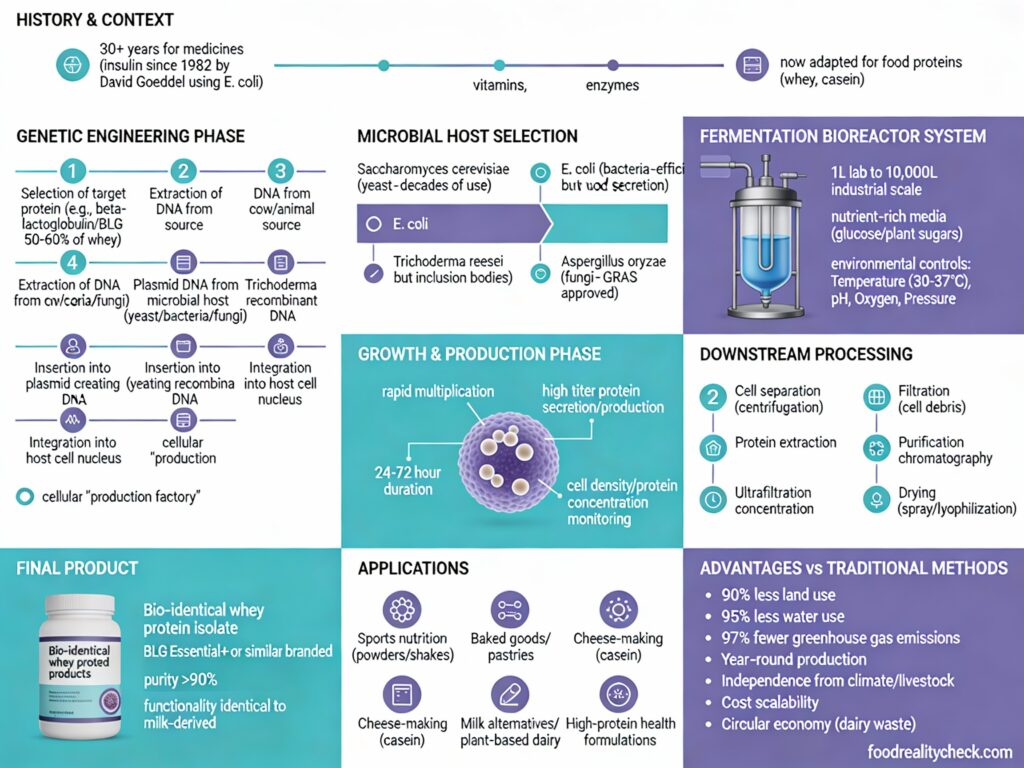

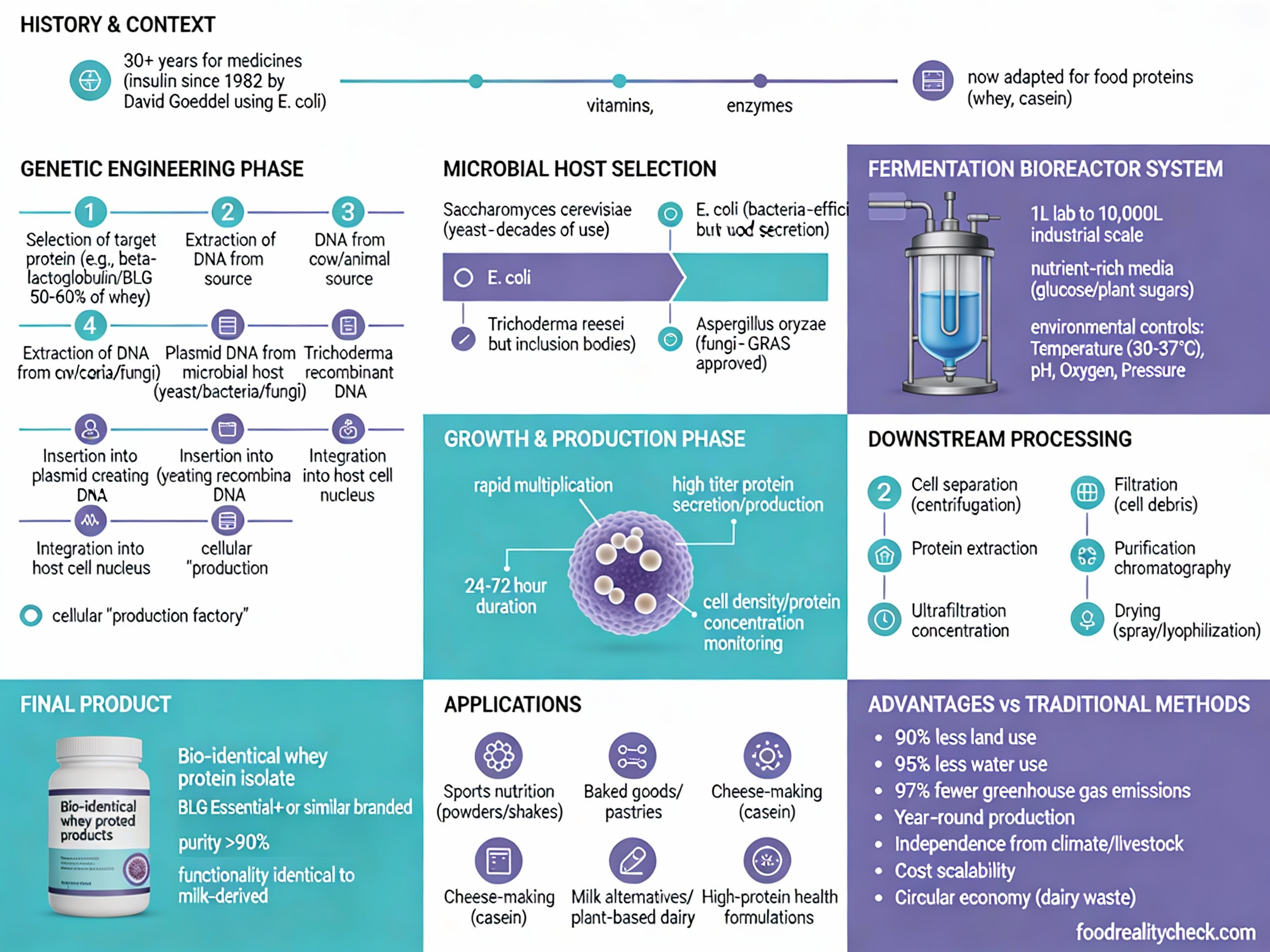

Precision fermentation is a biotechnology process that uses genetically programmed microorganisms—like yeast, bacteria, or fungi—to manufacture specific proteins and other food ingredients. Rather than relying on animals or plants, these microscopic “factories” are programmed with DNA instructions to produce exact molecular copies of proteins found in milk, eggs, or meat, or to create entirely novel compounds with desired nutritional properties.

The technology represents a fundamental shift in how we produce food ingredients. While traditional fermentation (used in beer, wine, and yogurt production) creates a mixture of different compounds, precision fermentation produces a single, pure target molecule with remarkable consistency.

Although the term “precision fermentation” is relatively new, the underlying science has been in use since the 1980s. Insulin for diabetes treatment and chymosin (rennet for cheese-making) have been produced through these techniques for decades and are now industry standards.

🔑 Quick Facts About Precision Fermentation

- Technology Origin: Developed in the 1980s; used commercially since then

- Organisms Used: Bacteria, yeast, fungi, and engineered microbes

- Products Made: Dairy proteins (whey, casein), meat proteins, fats, enzymes, vitamins, and flavor compounds

- First FDA Approval: October 2025 – Verley’s precision-fermented dairy proteins received FDA “No Questions” letter

- Key Companies: Perfect Day, Change Foods, Geltor, ImaginDairy, Remilk, Verley, and others

- Market Status: Early commercial phase; expanding rapidly across dairy, meat alternatives, and specialty ingredients

How Does Precision Fermentation Work?

The process involves three primary stages, each critical to producing pure, food-grade ingredients:

The Three-Step Process

- Strain Engineering: Scientists create a blueprint by identifying the genetic instructions that code for the desired protein or ingredient. This DNA is inserted into a microorganism (usually yeast or bacteria), transforming it into a specialized “production host.” Sometimes the organism’s own genes are edited or removed to optimize efficiency.

- Fermentation (Upstream Processing): The engineered microorganism is grown in a controlled environment called a bioreactor—essentially a large, temperature-controlled vessel. It’s fed simple sugars (like sucrose) and other nutrients that the microbe metabolizes. As the organisms multiply and feed, they produce the desired protein or compound, which accumulates in the fermentation broth.

- Purification (Downstream Processing): Once the microbes have produced sufficient quantities, the protein is separated from the microorganisms, filtered, purified, and dried into the final food ingredient. The microorganisms themselves are not present in the final product—they’re removed during processing.

This is fundamentally different from traditional animal agriculture. A dairy cow produces milk through a complex biological process involving grazing, digestion, and lactation. Precision fermentation replicates the protein itself, without the animal. The microbes essentially become “biological reactors” that convert simple inputs (sugar and nutrients) into complex, nutritionally valuable outputs.

The Role of Genetics

The key innovation is genetic precision. Scientists use DNA sequencing and synthetic biology tools to identify the exact genetic code responsible for producing a target protein. This code can be copied from nature (extracted from a milk protein gene, for example) or designed from scratch. Modern tools like CRISPR allow scientists to edit genes with surgical precision, removing unnecessary genes and optimizing the strain’s productivity.

The engineered strains are designed for specific advantages: faster growth, higher protein yields, lower production costs, and cleaner final products. As production scales, these microbes have been refined through thousands of iterations to maximize efficiency.

Real-World Applications

Precision fermentation is revolutionizing multiple food categories. Here’s where the technology is being applied today:

Dairy Proteins (Whey & Casein)

Several companies are producing milk proteins identical to those found in dairy milk, enabling animal-free versions of cheese, ice cream, yogurt, and milk beverages. ImaginDairy has created dairy products with only four ingredients using fermented whey. Perfect Day has launched precision-fermented ice cream. Change Foods focuses on casein for animal-free cheese. These proteins deliver the exact nutritional profile and functional properties of conventional dairy without requiring cows.

Meat Proteins & Muscle-Building Compounds

Companies like Fybraworks Foods and others are engineering fermented proteins that mimic the amino acid profiles and textures of meat. Some are adding heme (an iron-containing molecule that gives meat its distinctive flavor and color) produced through fermentation by companies like Impossible Foods, which was an early adopter of precision fermentation for flavor molecules.

Eggs & Egg Proteins

Onego Bio specializes in egg proteins produced without any poultry involvement. These proteins replicate the binding, emulsifying, and nutritional properties of real eggs, opening possibilities for egg-free baking, mayonnaise, and protein supplements.

Fats & Lipids

Companies like Nourish Ingredients are using precision fermentation to create specialty fats and oils that deliver the right taste, texture, and nutritional profile for plant-based foods. These replace coconut oil, palm oil, or other traditional sources with fermented alternatives.

Enzymes, Vitamins & Functional Compounds

Beyond proteins, precision fermentation produces vitamins (like B vitamins), enzymes (like proteases for meat tenderizing), flavor compounds (vanillin, citric acid), and pigments (like beta-carotene). Many of these have been produced industrially through fermentation for decades.

Environmental & Sustainability Benefits

One of the most compelling reasons for adopting precision fermentation is its dramatic environmental advantage over conventional agriculture.

Precision-fermented dairy and egg proteins can reduce emissions by up to 70% compared to animal agriculture

Requires 80% less water than conventional dairy and egg production

Uses 95% less land, preserving ecosystems and preventing deforestation

Reduces energy consumption by using controlled bioreactors instead of large-scale animal operations

Traditional livestock farming is a major driver of climate change, accounting for significant greenhouse gas emissions, water depletion, and land use. Precision fermentation sidesteps these challenges entirely. The microbes grow in contained vessels under optimized conditions, requiring minimal resources. A facility producing fermented proteins occupies a fraction of the space needed for cattle ranches or poultry farms.

Circular Economy Potential

Precision fermentation can utilize waste streams as feedstock. Some facilities are exploring the use of agricultural byproducts, food waste, and even CO₂ as inputs, turning waste into valuable ingredients. This closed-loop approach amplifies the sustainability benefits.

Biodiversity Impact

By reducing reliance on large-scale monoculture farming and pastureland, precision fermentation helps preserve natural ecosystems and their biodiversity. Forests that would otherwise be cleared for agriculture can remain intact, supporting wildlife and carbon sequestration.

Is It Safe? What Does the Research Show?

Precision fermentation products are safe for consumption and have regulatory support from major food authorities worldwide.

FDA Position & Approvals (United States)

In October 2025, the U.S. Food and Drug Administration (FDA) issued a groundbreaking “No Questions” letter to Verley, a French biotech company, confirming the safety of two precision-fermented dairy proteins. This was the first FDA approval of its kind for functionalized dairy proteins made through precision fermentation.

The FDA’s review evaluated five independent production batches for over 10 parameters including purity, composition, allergenicity, and digestibility. The approval paves the way for these ingredients to be commercialized in the U.S. market beginning in 2026. In the U.S., precision-fermented ingredients can be labeled as “whey protein from fermentation” or similar transparent language.

GRAS Status (Generally Recognized As Safe)

Multiple precision fermentation companies have achieved GRAS status, a formal recognition by the FDA that their ingredients are safe under specified conditions of use. This designation is based on scientific evidence and expert consensus. Verley’s self-affirmation of GRAS status in early 2025 strengthened its FDA application.

Scientific Research & Consensus

The underlying technologies have been used for over 40 years. Insulin produced through microbial fermentation has been used to treat millions of diabetics since the 1980s with an excellent safety record. Chymosin (rennet) produced through fermentation has been used in cheese-making for decades.

The key safety consideration is that purification processes ensure genetically engineered microorganisms are completely removed from the final product. The end result is a pure, molecularly identical protein that is chemically indistinguishable from the same protein found in nature.

Scientific evidence supports the safety profile. Studies document the purity and composition consistency across production batches, and independent testing confirms the absence of contaminants or altered properties.

Allergenicity & Labeling

Like any dairy protein, precision-fermented whey contains the same allergens as conventional whey. However, the controlled production process ensures consistent purity and composition. Food labels clearly identify these as dairy proteins, allowing consumers with allergies to make informed choices. The transparency in labeling has been a priority for manufacturers, with support for consumer-friendly language like “whey protein from fermentation.”

Products Available Today

Precision fermentation has moved beyond the laboratory. Here are commercial products and brands currently available or launching soon:

| Company | Product Category | Status |

|---|---|---|

| Perfect Day | Dairy proteins (whey, casein); ice cream, protein powder, chocolate | Available in select U.S. markets |

| Remilk | Non-animal dairy proteins (whey, casein) | Partnerships with General Mills and others |

| Change Foods | Animal-free cheese proteins (casein) | In development; scaling up |

| Geltor | Collagen and designer proteins | Available for beauty, food, and nutraceutical brands |

| Verley (formerly Bon Vivant) | Functionalized whey proteins (FermWhey™) | FDA approved; launching U.S. market 2026 |

| Strive Nutrition | FREEMILK (lactose-free, animal-free dairy) | Available in Kansas, expanding |

| ImaginDairy | Dairy proteins for milk, ice cream, yogurt, cream cheese | Scaling production; partnerships underway |

| Onego Bio | Egg proteins (animal-free) | In commercial development |

Many of these products are available online or in specialty retailers. Perfect Day’s ice cream and protein powder are among the most widely available consumer products to date. As production scales and costs decline, precision fermentation ingredients will become increasingly common in mainstream foods.

The Bottom Line

Precision fermentation represents a paradigm shift in food production. It offers a way to create nutritionally identical proteins to those from animals, without the animals. The technology delivers on three critical fronts:

1. Taste & Nutrition: Because precision fermentation produces authentic dairy, egg, and meat proteins, the nutritional profile and sensory properties are identical to conventional sources. There’s no “imitation”—these are the real proteins, just made differently.

2. Sustainability: The environmental case is compelling. With up to 70% lower emissions, 80% less water, and 95% less land use compared to animal agriculture, precision fermentation can significantly reduce the food system’s environmental footprint.

3. Safety & Regulation: Decades of research support the safety of fermented proteins. Recent FDA approvals validate that these ingredients meet rigorous food safety standards. Scientific evidence and expert consensus confirm their safety in human consumption.

You can feel confident about precision fermentation ingredients in your food. The technology has a long track record (insulin, for instance), undergoes rigorous safety testing, and is now achieving regulatory approval from major food authorities. As precision fermentation scales, consumers will have access to more sustainable, animal-free alternatives without sacrificing nutrition, taste, or quality.

This is not fringe biotechnology—it’s a practical solution to one of the world’s most pressing problems: how to feed a growing population sustainably. Precision fermentation will likely become an essential tool in our food system over the next decade.