Precision fermentation produces real dairy proteins (casein, whey) using genetically modified microorganisms—without involving cows. Understanding genetic engineering, fermentation scale-up, and protein identity reveals that precision-fermented milk proteins are biochemically identical to cow milk, making them “real dairy” in every meaningful way.

What Is Precision Fermentation

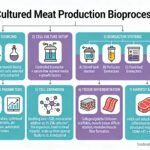

Precision fermentation uses genetically modified microorganisms (bacteria, fungi, yeast) to produce specific proteins: (1) Insert gene (casein, whey gene from cow DNA) into microorganism. (2) Organism ferments using standard bioreactor process. (3) Organism produces desired protein as byproduct of fermentation. (4) Protein is extracted, purified. (5) Result: real dairy protein produced without cows.

Precision fermentation is literally borrowing cow genes to make microbes produce milk proteins—the protein product is identical to cow milk protein.

Genetic Engineering Process

Process: (1) Gene isolation: Casein/whey gene extracted from cow DNA. (2) Vector construction: Gene inserted into plasmid (circular DNA) with promoter (activating sequence). (3) Transformation: Plasmid introduced into host organism (usually Saccharomyces cerevisiae yeast or E. coli bacteria). (4) Selection: Organisms successfully transformed selected. (5) Verification: Sequencing confirms correct gene insertion.

The modified organism is essentially a biological factory—fed sugar, produces milk protein.

Fermentation & Scale-Up

Once engineered, organism ferments normally: (1) Organism cultured in bioreactor (same as cultivated meat). (2) Fed simple nutrients (glucose, nitrogen sources). (3) Organism metabolism produces casein/whey as byproduct. (4) Fermentation lasts 3-5 days (bacteria) to weeks (yeast). (5) Bioreactor volume scales to industrial production (thousands of liters).

The beauty of precision fermentation: once organism is engineered, production uses standard industrial fermentation infrastructure.

Protein Purification

After fermentation, protein recovery: (1) Fermentation broth contains organism cells, proteins, other molecules. (2) Cells separated by centrifugation. (3) Proteins isolated through chromatography (separation by molecular properties). (4) Purified protein concentrated, dried. (5) Final product: milk protein powder essentially identical to whey/casein powder from cow milk.

Purification is standard protein chemistry—nothing extraordinary, well-established industrial process.

Biochemical Identity

Key fact: The casein produced by engineered microorganism is biochemically indistinguishable from cow casein. Why: Both proteins are produced from the same genetic instruction (casein gene). Structure: Identical amino acid sequence, identical 3D structure, identical function. Implication: Precision-fermented milk protein IS real dairy protein—not substitute, not analog, not artificial.

There is literally zero difference between cow-produced casein and precision-fermented casein—they’re the same molecule.

Regulatory & Safety

FDA approval: Precision-fermented rennet approved (approved before 2000). Precision-fermented hemoglobin (plant-based burger ingredient) approved 2018. Safety assessment: Focus on host organism (not pathogenic), gene inserted (from food source, safe), purification process (removes organism cells). Key insight: Protein product doesn’t need approval—only the organism and process do.

Precision fermentation has been approved for 20+ years—existing technology, proven safety.

Commercial Applications

Current use: Enzymes (rennet, lactase), some cheese production. Future: Casein/whey for cheese, yogurt, protein powders. Advantage over cow milk: (1) No antibiotic use. (2) Consistent composition (no seasonal variation). (3) No lactose (can be engineered out). (4) Potentially lower cost at scale. (5) Environmental advantages (no methane emissions).

Precision fermentation is complement to cow milk, not replacement—suited for specific ingredients (cheese base proteins, isolated proteins) rather than drinking milk.