From raw ingredients to individually wrapped fitness fuel.

The Overview

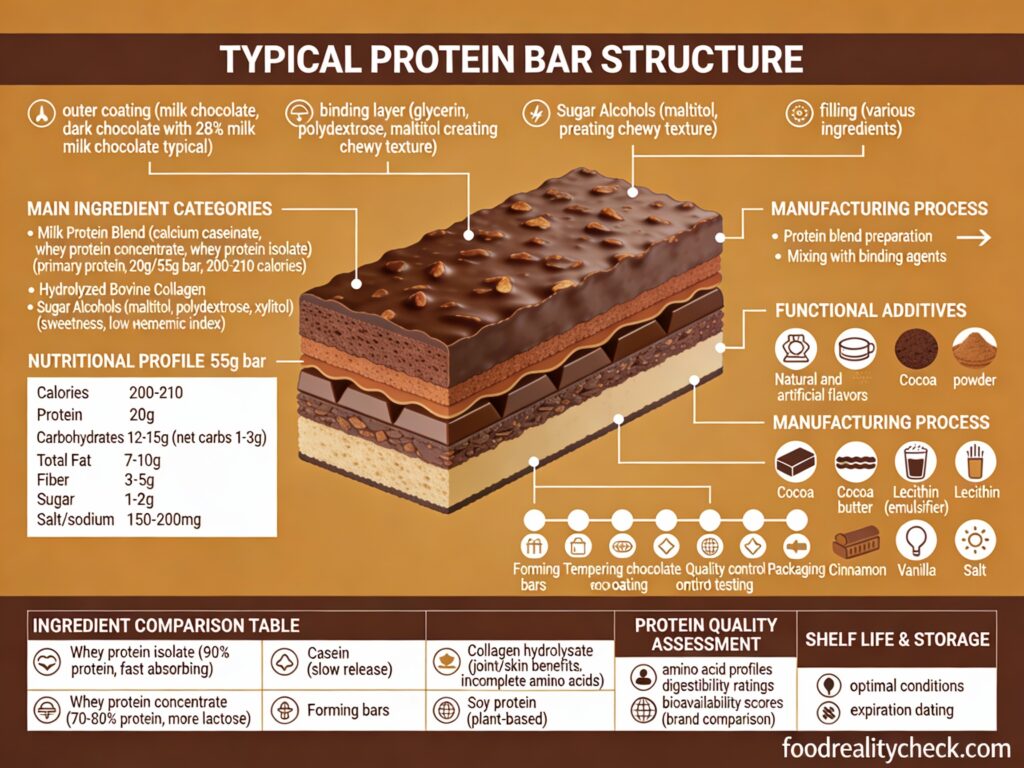

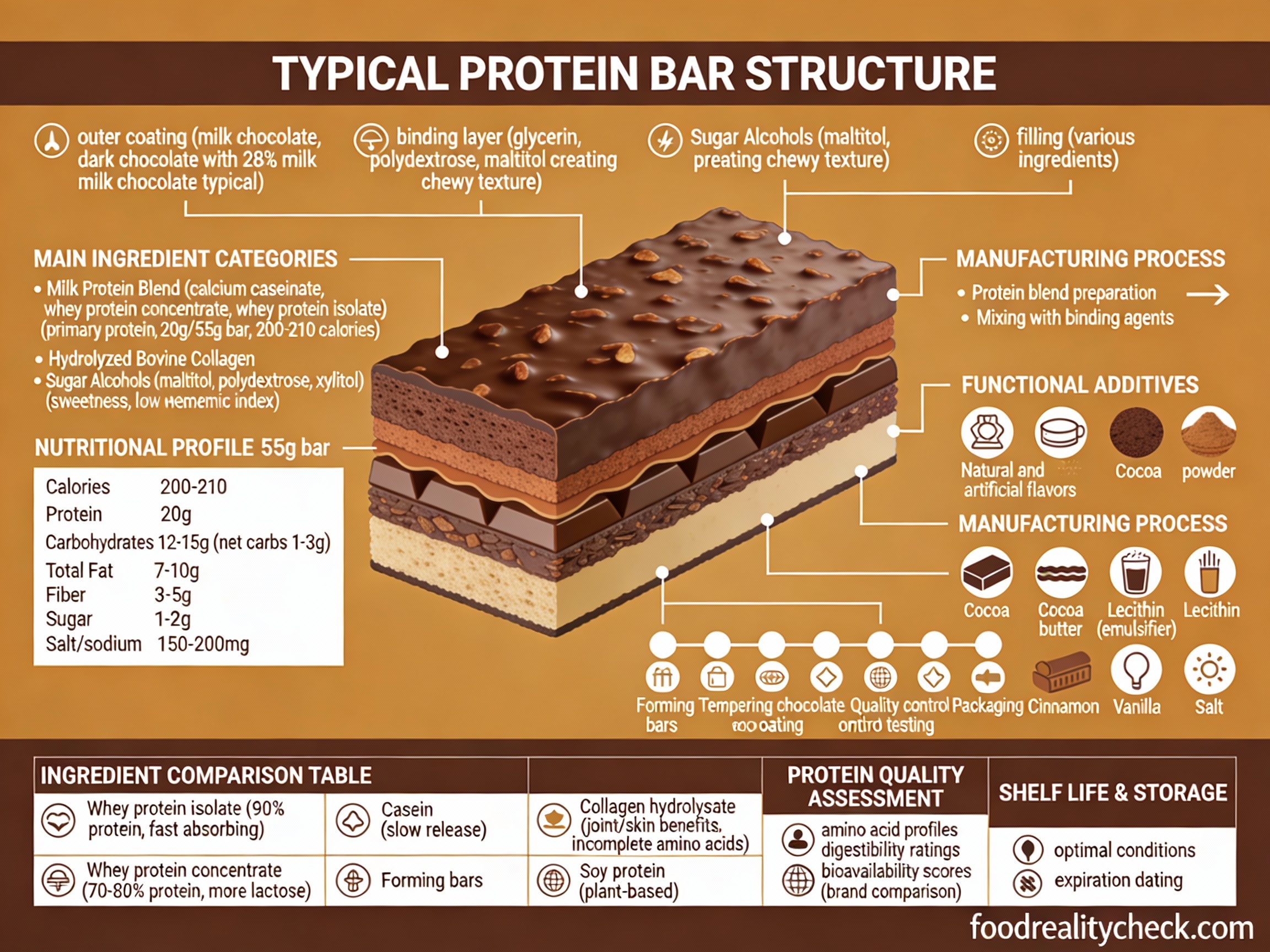

Protein bars are engineered nutrition products designed to deliver convenient, portable protein with appealing texture and taste.

The manufacturing process combines precise ingredient mixing, compression, extrusion, coating, and packaging at industrial scale.

Here’s exactly what happens from ingredient sourcing to finished snack bars.

🥘 Main Ingredients

• Protein powder (whey, casein, plant-based)

• Sweeteners (sugar, sugar alcohols, stevia)

• Binders (fibers, gums, thickeners)

• Fats (vegetable oil, nut butter)

• Flavorings and chocolate coating

Step 1: Ingredient Sourcing & Preparation

Raw materials—protein powders, sweeteners, binders, and flavorings—are sourced from suppliers and arrive at the factory in bulk containers.

Ingredients are inspected for quality, moisture content, and contamination using optical scanners and laboratory testing.

Each ingredient batch is tested to ensure nutritional specifications and safety standards are met before blending begins.

Step 2: Weighing & Pre-Mixing

All ingredients are precisely weighed in exact ratios using automated dosing systems that measure grams or fractions of grams.

Dry ingredients (protein powder, sweeteners, fibers) are mixed first in a planetary mixer, which gently blends without maceration.

This ensures even distribution and prevents premature activation of binding agents.

Step 3: Wet & Dry Ingredient Mixing

Wet ingredients (glycerol, oils, nut butters) are slowly added to the dry mixture while the blender continues rotating.

Advanced spiral mixers with multiple rotating arms ensure that all 20-30 individual ingredients are uniformly combined into a cohesive dough.

This step typically takes 5-10 minutes and is critical for ensuring identical nutritional and taste profiles across all bars.

Step 4: Heating & Temperature Control

The mixed dough is heated to 40-60°C (104-140°F) to make it more pliable and easier to form.

Gentle heat activates the binding agents (xanthan gum, carrageenan, cellulose) without damaging protein structure.

Temperature control is precise—too hot and protein denatures; too cool and the mixture becomes difficult to shape.

Step 5: Homogenization

The heated dough passes through a high-shear homogenizer that eliminates lumps, air pockets, and inconsistencies.

This ensures every bar has uniform texture—no grainy, chalky, or sandy mouthfeel from undissolved protein powder.

Homogenization also breaks down fat globules into microscopic droplets for smoother texture.

Forming the Bar: Compression and Extrusion

Step 6: Compression into Sheets

The homogenized dough is transferred to large industrial rollers that compress it into thin, uniform sheets.

Hydraulic presses apply controlled pressure (typically 50-150 PSI) to create density without crushing the mixture.

The compressed sheets flow onto a conveyor belt and pass through cooling zones to firm up slightly, preparing them for cutting.

Step 7: Extrusion & Bar Forming

The compressed sheets are fed into an extrusion system where they pass through a die (a specially shaped mold).

The die determines the bar’s shape, width, and dimensions—whether standard rectangular bars, smaller bites, or round energy balls.

Continuous extrusion creates a long bar that moves down the production line for cutting.

Step 8: High-Speed Cutting & Portioning

A guillotine cutter with computer-controlled precision slices the extruded bar to exact lengths (typically 40-65 grams).

Weight control sensors ensure each bar is within ±1-2 grams of specification, maintaining consistency across millions of bars.

Defective bars (off-weight, broken, malformed) are automatically rejected and recycled back into the mixer.

Step 9: Coating Application (Chocolate or Yogurt)

Individual bars pass through an enrober machine that dips them in melted chocolate, yogurt coating, or other toppings.

The coating is applied at controlled temperature (typically 35-45°C for chocolate) to create a uniform, thin layer.

Excess coating is blown off using compressed air jets, ensuring consistent weight and appearance.

Step 10: Cooling & Setting

Coated bars travel through a 40-50 meter cooling tunnel maintained at 15-18°C to solidify the chocolate or coating.

This rapid cooling prevents bloom (white discoloration) and ensures the coating cracks cleanly rather than bending.

Bars are spaced on moving conveyors so they don’t touch—preventing sticking and ensuring even cooling on all sides.

Quality Control & Packaging

Step 11: Quality Inspection

As bars exit the cooling tunnel, AI-driven vision systems scan each bar for defects: cracks, coating inconsistencies, size deviations.

Bars must meet strict visual standards—off-color, broken, or misshapen bars are automatically rejected.

Many facilities still employ hand inspection as a final verification, removing any bars that passed automated inspection but appear questionable.

Step 12: Individual Wrapping

High-speed automated wrappers encase each bar in foil or plastic film at rates of 200-400 bars per minute.

The wrapper protects the bar from moisture, light, and oxidation, extending shelf-life to 12-24 months.

Labels and nutrition information are printed on the wrapper during the wrapping process.

Step 13: Carton Packing & Case Assembly

Individually wrapped bars are robotically packed into cardboard boxes (typically 12-30 bars per box).

Cartons are sealed, labeled with batch codes and expiration dates, and stacked for shipment.

Cases are arranged on pallets and moved to climate-controlled warehouses for distribution to retailers worldwide.

Why This Process?

Precise mixing and compression ensure uniform nutrient distribution and consistent texture across millions of bars.

Multiple heating and cooling stages develop flavor complexity while maintaining protein structure.

Chocolate coating and sealed packaging extend shelf-life and make the product visually appealing and portable.

What About Additives?

Most commercial protein bars contain:

• Binding agents (xanthan gum, cellulose) – for texture and cohesion

• Emulsifiers (lecithin, mono- and diglycerides) – for smooth mouthfeel

• Sweeteners (sugar alcohols like maltitol) – for sweetness without calories

• Flavoring agents – for taste variety

• Antioxidants – to prevent rancidity during storage

Premium bars may use fewer additives but risk separation, graininess, or shorter shelf-life.

The ingredient list reveals product quality—short, recognizable lists suggest better formulation; long, chemical-sounding lists suggest more processing aids.

The Bottom Line

Protein bar manufacturing is a highly engineered process that combines food science, precision machinery, and quality control.

It creates shelf-stable, nutritionally balanced snacks that millions rely on daily for convenient protein supplementation.

Now you understand exactly how your protein bar goes from raw powder to individually wrapped fitness fuel.