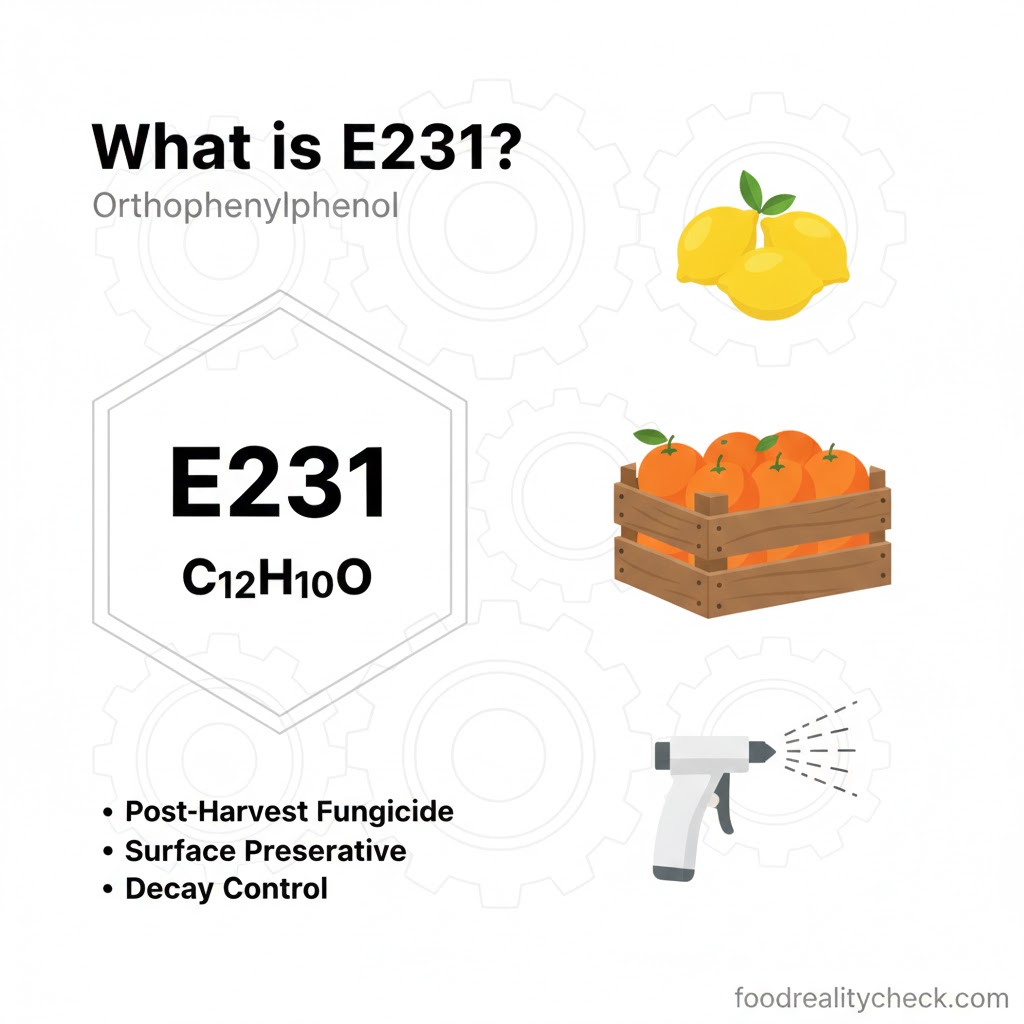

What is E231?

Complete guide to understanding E231 (Orthophenylphenol) in your food

The Quick Answer

E231 is orthophenylphenol (2-phenylphenol), a synthetic organic fungicide used as a preservative to prevent mold and fungal growth primarily on citrus fruits during storage and transportation.

It’s used exclusively as a post-harvest surface treatment on fruit—particularly citrus—to extend shelf life and prevent spoilage. Unlike its precursor E230 (biphenyl), E231 has a hydroxyl group attached, making it related to but chemically distinct.

E231 represents one of the most controversial food additives now being phased out globally. The compound was “no longer a permitted food additive in the European Union” but remains allowed as post-harvest treatment in 4 EU countries and continues use in some other markets, though with declining industrial adoption.

📌 Quick Facts

- Category: Synthetic Preservative, Antifungal Agent, Fungicide, Biocide

- Source: Fully synthetic organic compound (petroleum-derived)

- Found in: Surface treatment of citrus fruits (oranges, lemons, grapefruit, tangerines) and other fruits

- Safety: NO LONGER APPROVED as food additive in EU; FDA approved; JECFA approved; still allowed post-harvest in 4 EU countries

- Natural or Synthetic: Fully synthetic

- Vegan/Vegetarian: Yes

- Key Concern: NOW CLASSIFIED as “toxic to humans and the environment”; carcinogen; neurotoxin; phasing out globally

- Chemical Formula: C₁₂H₁₀O; monohydroxylated biphenyl (2-hydroxybiphenyl)

The Critical Context

E231 orthophenylphenol represents a major regulatory reversal—formerly approved as food additive, now described as “toxic to humans and the environment” with designation as carcinogen and neurotoxin. The substance was “long considered harmless” but now belongs to a group of chemicals considered significantly dangerous, representing one of the clearest examples of additive regulatory reclassification based on safety evidence.

What Exactly Is It?

E231 is orthophenylphenol (2-phenylphenol), an organic compound consisting of a hydroxylated biphenyl structure with the molecular formula C₁₂H₁₀O and molecular weight of 170.21 g/mol. It is one of three isomers of monohydroxylated biphenyl (the difference being the position of the hydroxyl group; orthophenylphenol has the hydroxyl group in the “ortho” position).

Physically, E231 appears as a white to light pink crystalline solid with a mild aromatic odor. The compound is soluble in water and alcohol, making it suitable for liquid formulation applications. It is stable over wide temperature ranges and resistant to degradation, allowing use across various processing conditions.

Chemically, orthophenylphenol is classified as a weak organic acid due to its phenolic hydroxyl group. This hydroxyl group is critical to its biocidal properties—the mechanism through which it kills fungi and bacteria.

Where You’ll Find It

E231 appears exclusively on fruit surfaces:

• Oranges (the primary application)

• Lemons

• Grapefruit

• Tangerines and other citrus varieties

• Other fruits (apples, stone fruits, tomatoes, cucumbers—historically)

• Fruit packaging impregnation (disinfection purposes)

• Seed boxes (disinfection)

• Rarely in confectionery or processed foods

E231 is applied directly to fruit skin as a surface treatment to prevent mold and fungal colonization during storage and shipping. Like E230, it does not penetrate into fruit flesh—remaining exclusively on the exterior surface.

Why Do Food Companies Use It?

E231 performs one critical function, though with declining adoption:

Mold and fungal prevention during transport and storage: E231 prevents growth of Penicillium fungi and other molds on fruit surfaces during storage and long-distance shipping. This is economically critical—significant fruit losses occur without fungal preservation. However, unlike E230, E231 is actively being phased out despite regulatory approval in some jurisdictions.

Why it’s being phased out despite continued approvals: The classification of E231 as “toxic to humans and the environment,” combined with its designation as carcinogen and neurotoxin, has driven industry-wide shift toward alternatives even where E231 remains approved. This represents market-driven safety-motivated change beyond regulatory mandates.

Is It Safe?

E231’s safety status represents a major regulatory shift—from “long considered harmless” to classified as toxic and phased out despite some continued legal approvals.

Regulatory Status—Complex and Changing:

• EFSA (Europe): NO LONGER APPROVED as food additive; “no longer permitted as food additive” but still allowed as post-harvest treatment in 4 countries (Belgium, Greece, Italy, Portugal)

• FDA (USA): Approved; no explicit ADI specified

• JECFA (WHO/FAO): Approved

• Australia/New Zealand: Approved for post-harvest use

• Current classification: “Toxic to humans and the environment”

• Current classification: Now explicitly described as “toxic to humans and the environment”

• Carcinogenicity: Classified as carcinogen (mechanism and strength not specified in available sources)

• Neurotoxicity: Classified as neurotoxin—potential nerve/brain damage

• Environmental toxicity: Designated as aquatic toxic and environmentally persistent

• Regulatory action: Removal from approved food additives in EU (though continued post-harvest use in 4 countries)

• Industry response: Proactive phase-out despite regulatory approvals in many jurisdictions, indicating industry confidence in toxicity concerns

• Migration from packaging: E231 is used in food packaging disinfection and can migrate into food contents; EURL-SRM research documented migration and formation of “conjugates” that hide OPP presence in tested samples

• Conjugate formation: Research indicates E231 forms conjugated compounds in some foods (particularly coffee) that evade standard detection—creating unmeasured residue exposure

• Developmental effects: Limited data; concerns about developmental/reproductive effects not fully characterized

• Low oral toxicity historically reported: LD50 (rats) noted as 2700-3000 mg/kg—suggesting low acute toxicity, but this does not address chronic toxicity, carcinogenicity, or neurotoxicity

• Phytotoxic effects: Causes damage to some plants; indicates biological reactivity; sodium salt (E232) formulations noted to cause phytotoxicity at high pH levels

The Paradox of Continued Approvals: Despite being classified as toxic and carcinogenic, E231 remains approved in some jurisdictions (USA, Australia/New Zealand) and allowed post-harvest in 4 EU countries. This reflects regulatory lag—where regulatory systems have not yet incorporated emerging toxicity evidence into approval status. The industry’s proactive phase-out suggests recognition of toxicity concerns independent of formal regulatory prohibition.

Comparison with E230 and E232

E231 is part of a family of related citrus preservatives with increasingly recognized safety concerns:

• E230 (Biphenyl/Diphenyl): Precursor to E231; documented genotoxicity; still FDA-approved; increasingly phased out

• E231 (Orthophenylphenol/2-Phenylphenol): Hydroxylated form; now classified toxic; no longer approved as food additive in EU; still post-harvest permitted in 4 EU countries

• E232 (Sodium orthophenylphenol/SOPP): Sodium salt of E231; similar concerns; used at high pH requiring solution pH >12; similar phasing out; post-harvest use continuing in some regions

All three represent a class of additives now recognized as having serious safety concerns and being phased out despite some continued regulatory approvals.

Why Was It Approved Initially?

E231 orthophenylphenol was approved during an era of less rigorous toxicological testing:

The compound was approved as food additive in earlier regulatory periods when toxicological standards were less stringent and emerging toxicity evidence (carcinogenicity, neurotoxicity, bioaccumulation) was not yet formally characterized. Historical assumptions of safety have now been contradicted by more comprehensive toxicological assessment.

Production Method

E231 orthophenylphenol is produced through chemical synthesis:

1. Biphenyl (C₁₂H₁₀) is hydroxylated through oxidation reactions (using hydrogen peroxide, peracids, or chlorobenzene oxidation)

2. The hydroxylation can produce three isomers; orthophenylphenol is separated from the mixture

3. Alternative synthesis: Direct condensation of cyclohexanone to give cyclohexenylcyclohexanone, followed by dehydrogenation and rearrangement

4. The crude product is purified through distillation, crystallization, and further purification to meet specifications

All methods are fully synthetic—no natural sources exist. Food-grade E231 requires significant purification from industrial synthesis.

Natural vs Synthetic Version

E231 is entirely synthetic—there is no natural version.

Orthophenylphenol is entirely a synthetic organic compound created through petroleum-derived chemical synthesis. No natural sources exist.

Environmental and Sustainability

E231 production through petroleum-derived synthesis carries environmental costs. The compound’s classification as bioaccumulative and environmentally toxic makes it ecologically problematic. The compound is moderately volatile but may persist in some environmental contexts. Overall environmental impact is concerning and contributes to regulatory de-approval.

Natural Alternatives

Want to avoid E231? Alternatives for citrus preservation include:

• E233 (Thiabendazole): Synthetic fungicide; less controversial than E231; increasingly used replacement

• Imazalil: Synthetic fungicide; used as E231 alternative

• Natamycin (E235): Natural-origin fungicide

• Citral or essential oil coatings: Natural compound-based preservation

• Wax coatings: Physical barrier preservation without synthetic fungicides

• Modified atmosphere packaging: Reduced oxygen environment prevents mold growth

• Organic certification: No synthetic fungicide treatment

Consumer Actions to Minimize E231 Exposure

For consumers concerned about E231 exposure:

• Choose citrus from EU countries with E231 prohibition (most of EU except Belgium, Greece, Italy, Portugal)

• Select “organic” citrus (no E231 treatment)

• Wash fruit surfaces thoroughly with soap and water

• Peel fruit completely, discarding all skin

• Support producers using alternative preservation methods

• Reduce imported citrus consumption if concerned about residue exposure, particularly from countries using E231

The Bottom Line

E231 (orthophenylphenol) is a synthetic preservative that was historically “long considered harmless” but is now explicitly classified as “toxic to humans and the environment,” designated as carcinogen and neurotoxin, and NO LONGER APPROVED as food additive in the European Union—though still permitted for post-harvest treatment in 4 EU countries and approved in some non-EU markets.

E231 is used exclusively as a surface treatment on citrus fruits to prevent mold growth during storage and transport. The compound does not penetrate into fruit flesh and can be largely removed by washing.

The critical distinction of E231 is its regulatory reclassification from presumed safe to explicitly toxic. This represents one of the clearest examples of additive safety reassessment based on emerging evidence. The toxicity concerns (carcinogenicity, neurotoxicity, bioaccumulation, environmental persistence) have driven industry-wide phase-out even in jurisdictions where regulatory approvals persist.

The continuation of limited approvals in some jurisdictions despite EU de-approval and toxicity classification represents regulatory lag—where some regulatory systems have not yet incorporated emerging safety evidence into formal prohibition. The market-driven phase-out indicates that manufacturers and retailers themselves recognize toxicity concerns independent of formal regulatory action.

For consumers, E231 represents an additive undergoing active phase-out due to recognized safety concerns. Geographic sourcing matters significantly—EU-sourced citrus (except from Belgium, Greece, Italy, Portugal) is E231-free; citrus from countries continuing approval may contain residues. The regulatory divergence and explicit toxicity classification should alert consumers to significant concerns warranting minimization of exposure through washing, peeling, and selection of treated alternatives.