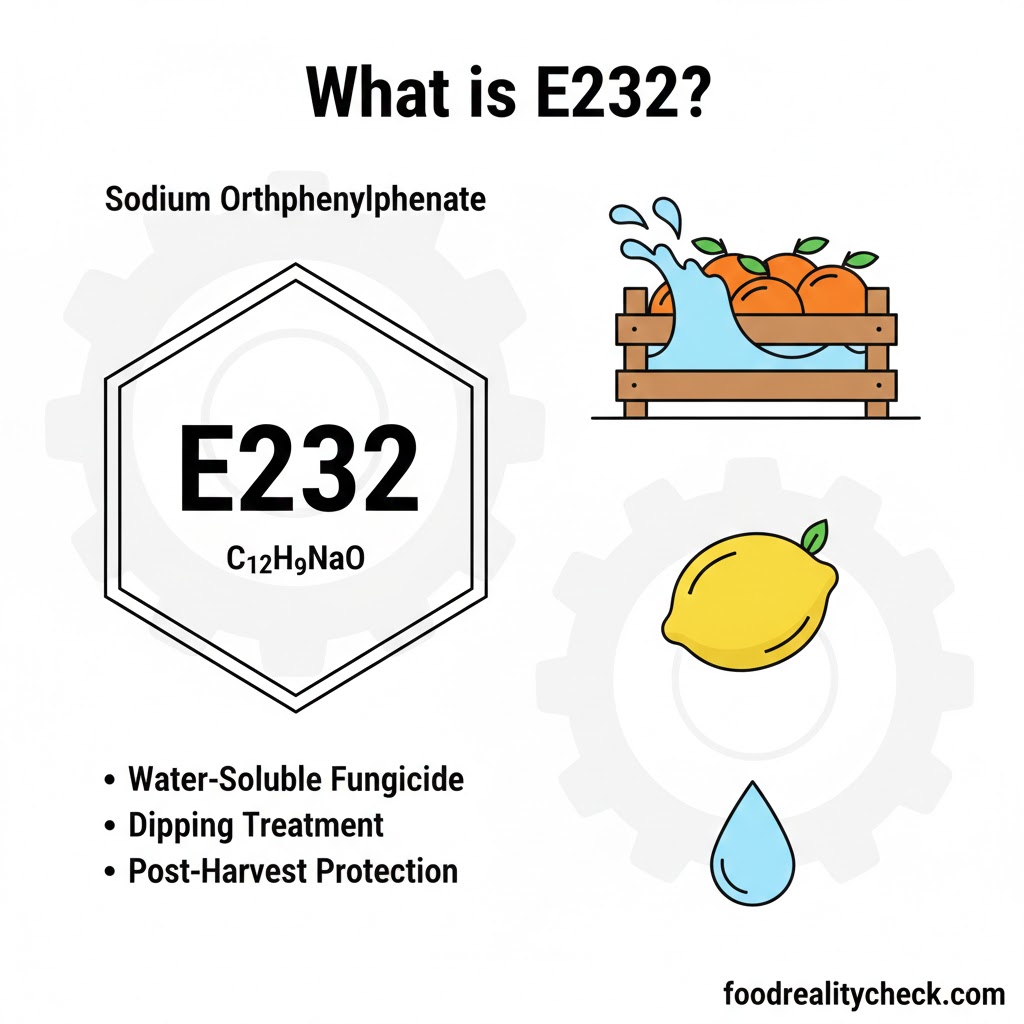

What is E232?

Complete guide to understanding E232 (Sodium Orthophenylphenol/SOPP) in your food

The Quick Answer

E232 is sodium orthophenylphenol (SOPP), the water-soluble sodium salt form of orthophenylphenol (E231), used as a preservative to prevent mold and fungal growth primarily on citrus fruits during storage and transportation.

It’s the sodium salt version of E231, offering enhanced water solubility compared to the free acid E231, allowing application in aqueous formulations and wax suspensions on fruit surfaces.

E232 represents the final and most controversial member of the biphenyl-family preservatives (E230, E231, E232), facing the same toxicity concerns as E231 with classification as carcinogen and neurotoxin, and undergoing active phase-out despite some continued regulatory approvals.

📌 Quick Facts

- Category: Synthetic Preservative, Antifungal Agent, Fungicide, Sodium Salt

- Source: Fully synthetic—sodium salt of orthophenylphenol (E231)

- Found in: Surface treatment of citrus fruits and other fruits, eggs, food packaging

- Safety: NO LONGER APPROVED as food additive in EU; FDA approved; JECFA approved; still allowed post-harvest in 5 EU countries

- Natural or Synthetic: Fully synthetic

- Vegan/Vegetarian: Yes

- Key Concern: CLASSIFIED as “toxic to humans and the environment”; carcinogen; neurotoxin; phasing out globally

- Chemical Formula: C₁₂H₉O₂Na; sodium salt of orthophenylphenol

The Critical Context

E232 sodium orthophenylphenol is the water-soluble version of E231, facing identical toxicity concerns and regulatory restrictions. Like E231, E232 was historically approved but is now explicitly classified as toxic to humans and the environment, designated carcinogen and neurotoxin, and undergoing active phase-out despite continued legal approvals in some jurisdictions. The compound faces even stricter geographic restrictions than E231 (E231 allowed post-harvest in 4 EU countries; E232 allowed post-harvest in 5 EU countries, requiring pH >12 for stability).

What Exactly Is It?

E232 is sodium orthophenylphenol (SOPP), the sodium salt of orthophenylphenol with molecular formula C₁₂H₉O₂Na and molecular weight of 192.19 g/mol.

E232 is chemically identical to E231 except for the sodium cation replacement, making it the water-soluble version of the free acid. While E231 is poorly soluble in water (insoluble in neutral pH), E232 dissolves readily in water at all pH levels, allowing formulation as aqueous solutions. This solubility difference is functionally critical—E232 allows liquid formulations for fruit dipping and wax suspension applications.

Physically, E232 appears as a white to light buff crystalline or powdered solid. Unlike E231 which is relatively stable across pH ranges, E232 requires alkaline pH (>12) for stability—it decomposes in acidic conditions. This pH dependence makes E232 application more technically complex than E231, requiring careful formulation to maintain alkalinity during storage and application.

Chemically, E232 functions identically to E231 in its biocidal mechanism: the orthophenylphenol anion penetrates fungal cell membranes and disrupts cellular metabolism, causing fungal death. The sodium cation is inert—serving only to facilitate water solubility.

Where You’ll Find It

E232 appears on fruit surfaces and in fruit-related products:

• Oranges (primary application)

• Lemons

• Grapefruit

• Tangerines and other citrus varieties

• Pome fruits (apples, pears) in some regions

• Other fruits in some applications

• Eggshell surface treatment (disinfection)

• Food packaging disinfection (can migrate into food)

• Fruit waxing formulations (aqueous wax suspensions)

E232 is specifically used in aqueous and wax formulations where its water solubility provides advantage over E231. It requires alkaline solution pH >12 for formulation stability.

Why Do Food Companies Use It?

E232 performs one critical function, with specific advantages in aqueous and wax formulations:

Mold and fungal prevention in aqueous formulations: E232’s water solubility allows application as aqueous dipping solutions or incorporation into wax suspensions—applications that E231 (the free acid) cannot support. This formulation advantage drives E232 selection where aqueous application is required. However, like E231, E232 is being phased out despite continued regulatory approvals due to toxicity concerns.

Is It Safe?

E232’s safety status is identical to E231—no longer approved as food additive in EU, classified as toxic to humans and environment, designated carcinogen and neurotoxin, undergoing global phase-out.

Regulatory Status—Complex and Changing:

• EFSA (Europe): NO LONGER APPROVED as food additive; still allowed post-harvest treatment in 5 EU countries (Cyprus, Greece, Spain, Croatia, Portugal)

• FDA (USA): Approved; no explicit ADI specified

• JECFA (WHO/FAO): Approved

• Australia/New Zealand: Approved for post-harvest use

• Current classification: “Toxic to humans and the environment”

🚨 IDENTICAL TOXICITY CONCERNS TO E231—NOW CLASSIFIED AS TOXIC: E232 faces identical safety concerns as its parent compound E231:

• Carcinogenicity: Classified as carcinogen (specific mechanism/strength not detailed in simplified documents)

• Neurotoxicity: Classified as neurotoxin—potential nerve/brain damage

• Environmental toxicity: Designated as toxic to aquatic life and environmentally persistent

• Bioaccumulation: May accumulate in tissues with chronic exposure

• Migration from packaging: EURL-SRM research documented E232 migration from food packaging into food contents; forms undetected conjugates

• Conjugate formation: Like E231, E232 forms sugar and fatty-acid conjugates in foods that evade standard detection methods, creating unmeasured residue exposure

• pH dependence concern: Requirement for pH >12 for formulation stability raises questions about how stability is maintained during actual food application and whether alkaline conditions persist

• Regulatory reclassification: From “long considered harmless” to explicitly toxic, representing major safety reassessment

Important distinction—E232 vs E231 solubility: While toxicity is identical, E232’s requirement for pH >12 formulation raises specific concerns about alkaline residues on fruit surfaces at pH far exceeding normal food pH. The safety implications of this extreme alkalinity requirement have not been comprehensively characterized.

The Conjugate Formation Problem—Undetected Residues

A critical issue with both E232 and E231 is formation of undetected conjugates:

EURL-SRM research documented that both E231 and E232 form conjugated compounds in certain foods (particularly citrus and coffee) that evade standard analytical detection methods. These conjugates include sugar conjugates (particularly glucose) and fatty-acid conjugates. This means that standard residue monitoring underestimates actual E232/E231 exposure—the compound is present in foods in conjugated form that requires special extraction procedures to detect. When standard “de-conjugation” methods are applied (acid hydrolysis), residue levels increase 28-35% in citrus and can increase significantly in other products. This creates uncertainty about actual consumer exposure to these compounds.

Comparison with E230 and E231

E232 is the water-soluble member of a concerning family of preservatives:

• E230 (Biphenyl): Precursor; documented genotoxicity; still FDA-approved; increasingly phased out

• E231 (Orthophenylphenol): Free acid form; poorly water-soluble; classified toxic; no longer approved as food additive in EU; phasing out

• E232 (Sodium orthophenylphenol): Water-soluble sodium salt; identical toxicity to E231; no longer approved as food additive in EU; identical phase-out trajectory

All three represent a family of additives now recognized as having serious safety concerns despite historical approvals.

pH Stability Concerns—E232-Specific Issue

A unique concern with E232 is its requirement for alkaline pH (>12) for formulation stability:

E232 cannot be formulated at neutral or physiological pH—it requires pH >12 (highly alkaline) for solution stability. This extreme alkalinity requirement raises questions: (1) How is this extreme pH maintained during fruit storage and transportation? (2) What are the alkalinity residues on fruit surfaces consumers contact? (3) Does the compound decompose during storage, creating breakdown products not characterized? (4) The safety characterization of E232 was presumably conducted under the intended pH >12 conditions; how applicable are these findings to actual fruit surface conditions where pH may drift neutral?

Production Method

E232 sodium orthophenylphenol is produced by salt formation of E231:

1. Orthophenylphenol (E231) is produced through hydroxylation of biphenyl as described in E231 guides

2. The orthophenylphenol is dissolved in aqueous sodium hydroxide solution

3. The sodium salt crystallizes or is recovered through precipitation/evaporation

4. The product is purified, dried, and standardized

5. Alternative: Direct neutralization of orthophenylphenol (E231) in suspension with sodium hydroxide solution, creating soluble sodium salt in situ

All production methods are fully synthetic.

Natural vs Synthetic Version

E232 is entirely synthetic—there is no natural version.

Sodium orthophenylphenol is entirely a synthetic compound created through petroleum-derived chemical synthesis followed by salt formation. No natural sources exist.

Migration from Food Packaging

A critical issue often overlooked—E232 (and E231) can migrate from food packaging into food contents:

E232 is used to disinfect food packaging materials and packaging surfaces. Unlike direct fruit treatment (which remains on fruit surface), packaging-incorporated E232 can migrate into packaged foods, particularly fatty or oily foods where the compound is lipophilic. EURL-SRM research documented this migration and documented that it forms undetected conjugates in some foods. This represents a second pathway of E232 exposure beyond direct fruit treatment.

Environmental and Sustainability

E232 production through petroleum-derived synthesis carries environmental costs. Identical to E231, the compound’s classification as bioaccumulative and environmentally toxic makes it ecologically problematic. The extreme pH requirement (>12 for stability) raises additional environmental questions about what happens to residues during processing, storage, and eventual environmental release.

Natural Alternatives

Want to avoid E232? Alternatives for fruit preservation include:

• E233 (Thiabendazole): Synthetic fungicide; less controversial; increasingly used replacement; can be formulated at neutral pH

• Imazalil: Synthetic fungicide; alternative with different chemical properties

• Natamycin (E235): Natural-origin fungicide; increasing adoption

• Citral or essential oil coatings: Natural compound-based preservation

• Wax coatings (non-phenolic): Physical barrier using non-E232 compounds

• Modified atmosphere packaging: Oxygen reduction prevents mold growth

• Organic certification: No synthetic fungicide treatment

Consumer Actions to Minimize E232 Exposure

For consumers concerned about E232 exposure:

• Choose citrus from EU countries prohibiting E232 (most of EU except Cyprus, Greece, Spain, Croatia, Portugal)

• Select “organic” citrus (no E232 treatment)

• Wash fruit surfaces thoroughly with soap and water (removes surface residue but not conjugates already in fruit)

• Peel fruit completely, discarding all skin

• Check packaging for E232 residue migration (fatty foods at risk)

• Reduce imported citrus and packaged fruit consumption if concerned about cumulative exposure

• Support producers using alternative fungicides

The Bottom Line

E232 (sodium orthophenylphenol/SOPP) is the water-soluble sodium salt version of E231, faces identical toxicity concerns and regulatory restrictions, is NO LONGER APPROVED as food additive in the European Union, yet remains allowed post-harvest in 5 EU countries and approved in some non-EU markets.

E232 is the water-soluble version selected when aqueous formulations or wax suspensions are required for fruit treatment. Unlike E231 (the free acid), E232 formulates readily in water solutions and aqueous wax—providing technical advantages that drove its historical preference despite identical toxicity to E231.

The critical distinction of E232 is identical to E231: regulatory reclassification from presumed safe to explicitly toxic. Classification as carcinogen, neurotoxin, and environmentally persistent, combined with documented bioaccumulation and conjugate formation in foods, has driven industry phase-out despite regulatory approvals.

A unique concern with E232 is its pH dependence—formulation stability requires pH >12 (highly alkaline), raising questions about surface residues and stability during fruit storage. Additionally, research documents that E232 (like E231) forms undetected conjugates in foods, meaning standard residue monitoring underestimates actual exposure.

E232 also migrates from food packaging into packaged foods, particularly fatty products—creating a second exposure pathway beyond direct fruit treatment. This packaging migration and conjugate formation represent less-recognized routes of E232 exposure.

For consumers, E232 represents an additive undergoing active global phase-out due to recognized carcinogenicity and neurotoxicity concerns. Geographic sourcing matters significantly—EU sourcing varies by country. The regulatory divergence (EU de-approval vs. continued approvals elsewhere) and explicit toxicity classification should alert consumers to serious concerns warranting minimization of exposure through washing, peeling, and selection of treated alternatives using safer fungicides.