The Quick Answer

E553 is magnesium silicate, an inert mineral-derived or synthetic anti-caking agent used to prevent clumping in dry, powdered foods while maintaining flow properties and spreadability.

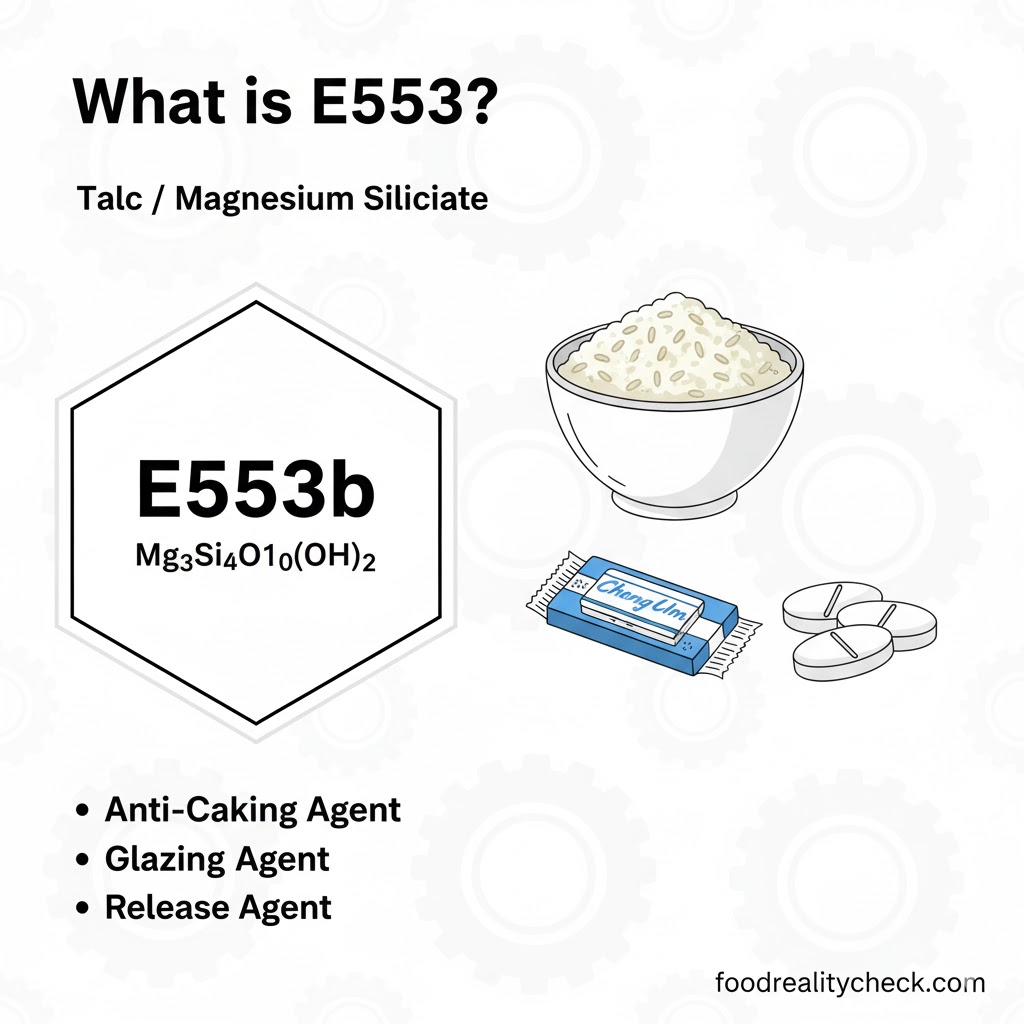

It exists in two primary forms: E553a (synthetic magnesium silicate) and E553b (talc, natural hydrous magnesium silicate). It’s used to keep salt, spices, powders, and dried foods free-flowing.

Most people consuming table salt, spices, powdered products, and dried foods occasionally encounter E553, though it remains essentially invisible in products—a flavorless, odorless additive providing purely functional benefit with no sensory properties.

📌 Quick Facts

- Category: Anti-caking Agent, Mineral-derived or Synthetic, Glidant

- Source: Synthetic magnesium silicate (E553a) or naturally mined talc (E553b)

- Found in: Salt, spices, powdered sugar, dried foods, cheese, food supplements, chewing gum, table-top sweeteners

- Safety: FDA GRAS approved; EFSA approved (with important 2018 re-evaluation caveat); JECFA ADI “not specified”

- Natural or Synthetic: E553a is synthetic; E553b is natural mineral (talc)

- Vegan/Vegetarian: Yes

- Key Concern: 2018 EFSA re-evaluation concluded “safety cannot be assessed” due to data gaps (not demonstrated harm, but insufficient data)

- Chemical Formula: xMgO·ySiO₂·zH₂O (E553a); Mg₃Si₄O₁₀(OH)₂ (E553b talc)

What Exactly Is It?

E553 is magnesium silicate, a mineral-based anti-caking agent existing in two distinct forms:

E553a – Synthetic Magnesium Silicate: A manufactured compound with the approximate formula xMgO·ySiO₂·zH₂O, created by combining magnesium compounds and silica sources. It appears as a white, fine, odorless powder that is insoluble in water. Synthetic magnesium silicate is hydrophobic (repels water), making it particularly effective at preventing moisture absorption in dry products. There are two sub-forms: E553a(i) regular magnesium silicate and E553a(ii) magnesium trisilicate.

E553b – Talc (Natural Hydrous Magnesium Silicate): A naturally occurring mineral with the chemical formula Mg₃Si₄O₁₀(OH)₂, mined from talc deposits (particularly from soapstone rocks). Talc is the most abundant and widely used form of E553, accounting for approximately 89% of all silicate usage in food according to EFSA data. Talc appears as a white powder with a slightly soapy texture and is chemically inert. The mineral is processed through flotation and purification to remove asbestos contamination.

Both forms are biologically inert minerals that are not absorbed in the gastrointestinal tract and pass through largely unchanged. They function purely as physical anti-caking agents, not participating in metabolic processes.

Where You’ll Find It

E553 appears in a wide range of dry, powdered foods:

• Table salt and salt substitutes

• Spices and spice blends

• Powdered sugar and dextrose

• Vanilla powder

• Dried herbs

• Powdered condiments and seasonings

• Cheese (sliced, grated, processed)

• Food supplements in powder/tablet form

• Chewing gum

• Baking powder and baking soda

• Powdered sweeteners

• Dried vegetables and potato flakes

• Rice (as glazing agent)

• Instant foods and dehydrated meals

• Whey powder preparations

• Dietary supplements (capsules, tablets)

• Pharmaceutical products

• Cosmetics and personal care products

E553’s presence in foods is essentially unnoticeable—it provides no flavor, aroma, or sensory properties, functioning purely functionally to maintain product flowability during storage and consumer use.

Why Do Food Companies Use It?

E553 performs one critical function:

Anti-caking and flow maintenance: E553 prevents clumping and caking of dry, powdered foods caused by moisture absorption and particle cohesion. By coating food particles and absorbing residual moisture, E553 maintains the free-flowing properties essential for packaged products—preventing hardened lumps forming in salt shakers, spice containers, and supplement bottles. Without E553, powdered products would develop large clumps making them difficult to dispense and use.

Why it’s selected: E553 is among the most inert and least controversial anti-caking agents available, with no flavor or aroma impacts. Manufacturers choose E553 for routine applications where simplicity and invisibility in the product are paramount. Alternative anti-caking agents (calcium silicate E552, calcium compounds) are often selected for specific applications but lack E553’s broad utility.

Is It Safe?

E553’s safety status is officially approved but faces important data limitations explicitly acknowledged by regulatory authorities.

Regulatory Status:

• FDA (USA): Generally Recognized As Safe (GRAS) when used at levels not exceeding 2% in table salt and in accordance with good manufacturing practice

• EFSA (Europe): Listed as authorized food additive (E553a(i), E553a(ii), and E553b)

• JECFA (WHO/FAO): ADI “not specified” since 1982

⚠️ Critical 2018 EFSA Re-evaluation—Safety Cannot Be Assessed: The European Food Safety Authority conducted a 2018 re-evaluation (published 2018 in EFSA Journal) with a critical conclusion that directly contradicts earlier assessments:”The Panel concluded that the safety of calcium silicate (E 552), magnesium silicate (E 553a(i)), magnesium trisilicate (E 553a(ii)) and talc (E 553b) when used as food additives cannot be assessed.”

This landmark statement reflects not demonstrated harm, but rather insufficient data. Specifically:

• Lacking subchronic and chronic toxicity data: No adequate studies on extended (weeks to months) exposure at food-use levels

• Lacking carcinogenicity data: Only one limited chronic study available (for calcium silicate, related but not identical compound)

• Lacking reproductive toxicity data: No studies assessing effects on reproduction or developmental processes

• Silicon accumulation in organs: Animal studies documented accumulation of silicon in kidneys and liver; human relevance unclear

• Limited absorption data: Studies document “very low” absorption, but exact mechanisms and extent remain incompletely characterized

• Particle size implications: Scanning electron microscopy data for talc indicate particle size 20-40 μm; long-term consequences of inhaled or ingested particles of this size remain partially unclear

• Human exposure uncertainty: Refined exposure assessment indicates higher consumption levels than previously estimated in children and specific consumer populations

• Asbestos contamination risk: While modern production processes include asbestos removal, historical talc products contained asbestos; current contamination risk is theoretically near-zero but complete elimination not always verified

Important distinction: The 2018 EFSA conclusion that “safety cannot be assessed” does not mean E553 is unsafe—it means there is insufficient scientific data to confidently establish safety at current use levels. This is different from finding harmful effects. The phrase reflects regulatory caution about data gaps rather than demonstrated toxicity.

Documented historical context:

• Decades of use without confirmed harm: E553 (particularly talc E553b) has been used in food for decades to over a century in some applications, with no documented epidemic of illnesses attributable to E553 consumption

• Cosmetic talc controversy: The primary modern talc controversy involves cosmetic/personal care talc potentially contaminated with asbestos or causing ovarian cancer—a different concern than food-grade E553, though the source mineral is identical

• Medicinal talc safety: Magnesium trisilicate (E553a(ii)) has been used medically as an antacid at doses of 0.5-1 g three times daily (up to 4 g/person/day) for decades without documented kidney effects in humans despite theoretical concern

• No confirmed cases in surveillance databases: Despite wide and long-term use, the EudraVigilance database (EU adverse event reporting system) contains no confirmed cases of kidney or organ damage from food-use E553

The Asbestos Question—Modern Risk

A critical question for talc E553b is asbestos contamination:

Historically, talc deposits in some mining regions contained asbestos contamination—a carcinogenic mineral fiber. Modern food-grade talc undergoes rigorous purification processes (flotation, magnetic separation, acid washing, heat sterilization) to remove asbestos before use as food additive. Current specifications require that food-grade talc “must not contain asbestos,” and manufacturing controls are designed to verify this.

However, the cosmetic talc lawsuits (where juries awarded damages for alleged talc-related ovarian cancer) have raised consumer awareness and concern about asbestos contamination in all talc products. For food-grade E553b, the risk is significantly lower due to more rigorous quality control than cosmetic-grade talc, but the concern remains psychologically present among consumers. This is a key reason some manufacturers have shifted to synthetic E553a or entirely different anti-caking agents.

Production Methods

E553a (Synthetic Magnesium Silicate) Production:

1. Magnesium sulphate and sodium silicate are combined and chemically reacted

2. The resulting precipitate is filtered and washed

3. The product is dried, milled into fine powder, and standardized

4. Alternative: Direct synthesis from mineral sources like sepiolite

E553b (Talc) Production:

1. Talc ore is mined from talc deposits (soapstone rocks)

2. The ore undergoes crushing and grinding

3. Flotation processing: ore is suspended in water with collector chemicals; air is bubbled through creating flotation separation of talc particles from other minerals

4. Magnetic separation removes iron-bearing minerals

5. Acid washing removes soluble salts and metals

6. The purified talc is filtered, washed, and dried

7. Heat sterilization (up to 200°C) may be applied to eliminate microorganisms and confirm asbestos absence

8. Micronization (grinding to very fine particles, 0.5-50 μm) may be applied to enhance properties

Natural vs Synthetic Version

E553 exists in both natural and synthetic forms:

E553a (Synthetic magnesium silicate): Fully synthetic, manufactured from chemical precursors. Creates a more uniform, controlled product with consistent properties and reduced asbestos contamination risk (zero, since created entirely through chemical synthesis).

E553b (Talc): Natural mineral extracted from earth. Uses naturally occurring hydrous magnesium silicate with inherent variation in composition and historical asbestos contamination concerns (now minimized through processing but never entirely eliminated).

For consumers seeking to minimize talc risk, foods labeled with E553a (synthetic magnesium silicate) avoid the historical asbestos concern entirely, though also sacrifice the “natural mineral” designation of talc.

Comparison with Related Anti-Caking Agents

E553 occupies a position among several anti-caking minerals:

• E552 (Calcium silicate): Similar mineral-based anti-caking agent; EFSA 2018 re-evaluation raised identical safety assessment concerns; broader temperature stability

• E553a (Synthetic magnesium silicate): Fully synthetic; zero natural variation; zero asbestos risk

• E553b (Talc): Natural mineral; historical asbestos contamination risk (now minimized); most widely used form

• E535 (Sodium ferrocyanide): Different anti-caking mechanism; used in some salt products

• Silicon dioxide (E551): Different mineral; different particle properties

• Calcium phosphates: Alternative mineral-based anti-caking agents with different properties

The choice among these reflects manufacturer preference for specific properties (particle size, moisture absorption, thermal stability) and increasingly, consumer perception about “natural” versus “synthetic” and asbestos risk.

Environmental and Sustainability

E553a (synthetic magnesium silicate) production requires chemical synthesis creating moderate environmental footprint. E553b (talc) involves mining, benefiting local economies but requiring land reclamation. Talc is a finite natural resource, though deposits are geographically widespread. Neither form poses aquatic or ecological toxicity concerns. Sustainability assessments are mixed: talc mining provides livelihoods but requires landscape restoration; synthetic alternatives avoid mining but require more energy-intensive manufacturing.

Natural Alternatives

Want to avoid E553? Food companies sometimes use these alternatives:

• E552 (Calcium silicate): Mineral-based; similar concerns and properties

• E551 (Silicon dioxide): Different mineral base; different particle properties

• Calcium phosphates: Alternative mineral; different moisture absorption properties

• Modified starch: Organic-based; less effective for some applications

• Gum arabic: Natural gum-based anti-caking agent

• No anti-caking agent: Accept clumping and recommend consumer action to break apart dried food

For consumers concerned about talc or mineral-based additives, identifying products explicitly labeled “anti-caking agent free” or those using non-mineral alternatives requires careful label inspection.

The Bottom Line

E553 (magnesium silicate) is an inert mineral anti-caking agent officially approved by FDA, EFSA, and JECFA, but the 2018 EFSA re-evaluation explicitly stated that safety cannot be assessed due to insufficient toxicity data—a critical caveat distinguishing this additive from most others.

E553 exists in two forms: E553a (synthetic magnesium silicate) and E553b (natural talc). Both function identically to prevent clumping in dry, powdered foods. E553 is not absorbed in the gastrointestinal tract and passes through largely unchanged. No genotoxicity or developmental toxicity is indicated in available data. Decades of use have generated no confirmed epidemic of illnesses attributable to food-grade E553.

However, the 2018 EFSA re-evaluation documented critical data gaps: lacking adequate subchronic and chronic toxicity studies, lacking carcinogenicity data, lacking reproductive toxicity data, and incomplete understanding of organ accumulation of silicon. This represents regulatory caution about insufficient evidence rather than demonstrated harm.

For talc specifically (E553b), the asbestos contamination concern, while minimized in modern food-grade products, remains a psychological concern for consumers due to well-publicized cosmetic talc litigation. Synthetic magnesium silicate (E553a) eliminates this concern entirely by being manufactured without mineral extraction.

The 2018 EFSA decision reflects increasingly rigorous regulatory standards applied to additives with limited historical safety data—a standard that might classify other long-used additives similarly if subjected to the same scrutiny. For consumers, E553’s use in routine anti-caking applications presents theoretical concern due to incomplete toxicity data, though historical experience suggests minimal practical risk. Those seeking to minimize exposure can identify “talc-free” products or those using alternative anti-caking agents, though true “anti-caking agent-free” products remain uncommon.