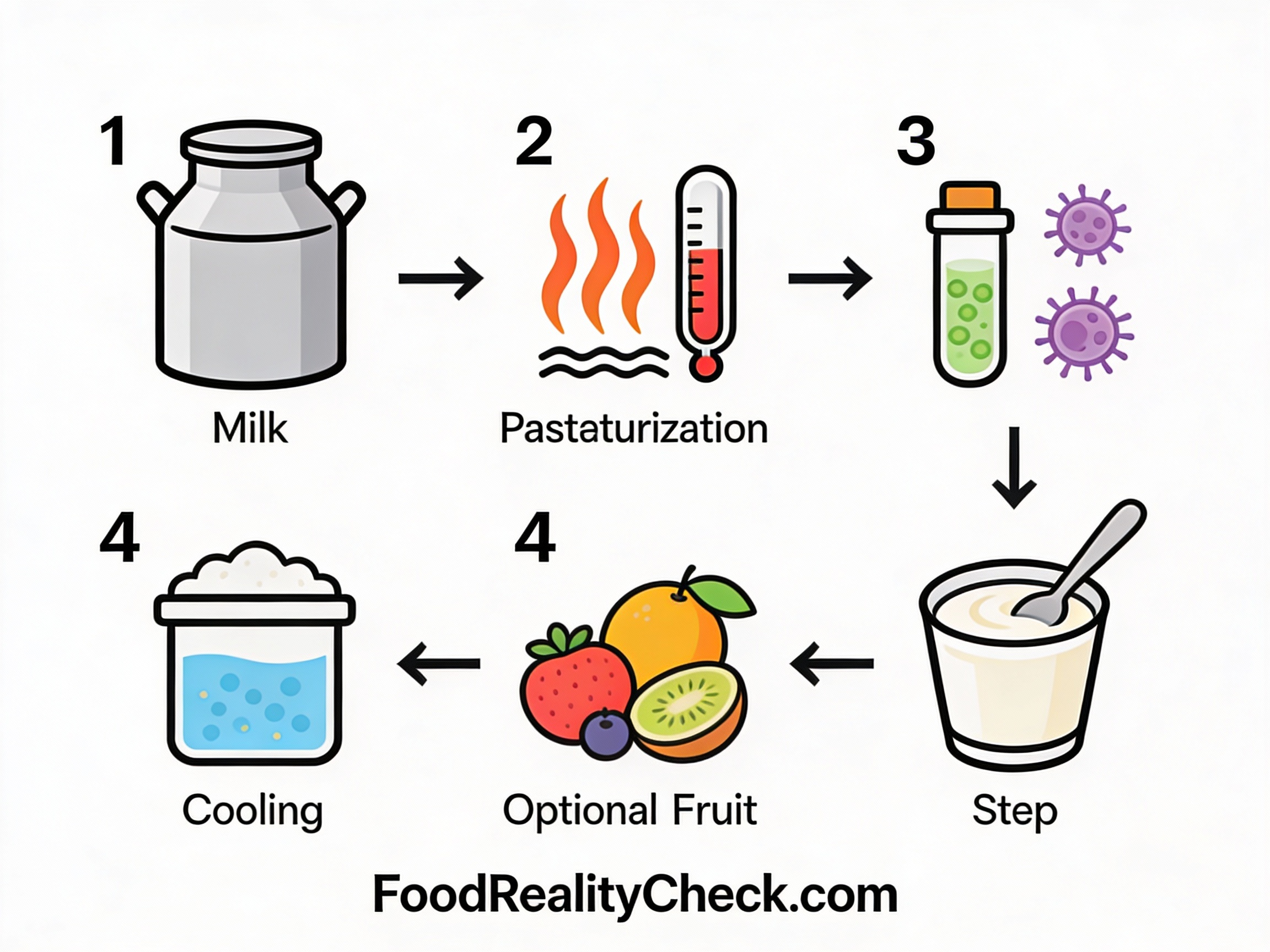

From milk to living culture through fermentation.

The Overview

Yogurt is created through bacterial fermentation—a living process where beneficial microorganisms transform milk into a tangy, probiotic-rich food.

The process relies on two specific bacterial strains, precise temperature control, and carefully timed fermentation to develop flavor, texture, and probiotic benefits.

Here’s exactly how milk becomes yogurt through microbial magic.

🥘 Main Ingredients & Cultures

• Milk (whole, low-fat, or skim)

• Streptococcus thermophilus (lactic acid bacteria)

• Lactobacillus delbrueckii subsp. bulgaricus (lactic acid bacteria)

• Additional probiotic cultures (optional, for probiotic yogurt)

Step 1: Milk Standardization & Preparation

Fresh milk arrives at the factory and is standardized—the fat content is adjusted to a specific percentage (skim, low-fat, or whole) based on the desired yogurt type.

Skim milk powder or whey protein concentrate is often added to increase dry matter content and create a thicker, creamier final product.

This pre-treatment ensures consistent texture and mouthfeel across all batches.

Step 2: Pasteurization & Heat Treatment

The standardized milk is heated to 80°C (176°F) for 15 minutes or flash-pasteurized at 72°C (162°F) for 15 seconds.

This heat treatment kills pathogenic bacteria and spoilage organisms, creating a clean slate for yogurt cultures.

Critically, heat also denatures whey proteins (80-85%)—denatured proteins have enhanced water-binding capacity, which improves yogurt’s firmness and reduces whey separation.

Step 3: Homogenization

The pasteurized milk passes through a homogenizer under high pressure (100-200 MPa) that breaks down fat globules into uniform microscopic droplets.

This prevents cream from separating and floating to the surface, creating a smooth, consistent product.

Homogenization also facilitates easier whey protein incorporation into the casein network during fermentation.

Step 4: Cooling & Culture Inoculation

The pasteurized milk is cooled to 43-46°C (109-114°F)—the optimal temperature for yogurt cultures.

At this temperature, 2-3% of starter culture is added. This culture contains live Streptococcus thermophilus and Lactobacillus bulgaricus in precise ratios.

The inoculation is done carefully and aseptically to prevent contamination by unwanted bacteria.

Step 5: The Fermentation Process (Hours 0-4)

The inoculated milk is transferred to large fermentation tanks where it remains at a constant 43-46°C.

Streptococcus thermophilus begins metabolizing lactose, producing lactic acid and gradually lowering the pH from ~6.7 to ~5.0.

As the pH drops, Lactobacillus bulgaricus becomes increasingly active, further acidifying the milk.

Step 6: Curdling & Coagulation (Hours 4-8)

As lactic acid is produced and pH drops to approximately 4.6, the milk’s casein proteins lose their negative electrical charge and begin to aggregate into a gel-like network.

This coagulum traps water, fat, and nutrients, transforming liquid milk into yogurt’s characteristic thick consistency.

Lactose levels drop by approximately 30%, being converted into lactic acid and flavor compounds (esters and peptides) that give yogurt its distinctive tang.

The Finishing Steps: Cooling & Packaging

Step 7: Reaching Target Acidity

Fermentation continues until the yogurt reaches the desired acidity level (typically pH 3.8-4.2, equivalent to 0.8-1.2% lactic acid).

Industrial facilities monitor pH continuously using real-time sensors and automatically trigger cooling when targets are reached.

Fermentation typically takes 4-8 hours depending on temperature, culture strength, and desired acidity.

Step 8: Rapid Cooling (Cut-off Phase)

Once target pH is reached, the yogurt coagulum is rapidly cooled to below 10°C to stop fermentation and halt bacterial activity.

Cooling is critical—if yogurt is cooled too slowly, over-acidification can break down the casein network, releasing whey (syneresis) and creating a grainy, separated product.

Rapid cooling also prevents overcurdling and helps preserve beneficial probiotic bacteria.

Step 9: Flavoring & Fruit Addition (Optional)

For flavored yogurts, fruit purees, fruit pieces, granola, honey, or other add-ins are blended into the cooled yogurt at controlled speeds.

Gentle mixing prevents disrupting the delicate casein network.

Sweeteners and flavoring agents are added to create the desired taste profile for different market segments.

Step 10: Final Cooling & Storage

The yogurt is further cooled to 5°C (41°F) for storage and maintains this temperature throughout distribution.

Cold storage slows bacterial metabolism dramatically, keeping the yogurt stable for 3-4 weeks.

The cultures remain alive but dormant, able to resume activity if incubated at warm temperatures (hence why homemade yogurt cultures remain viable in store-bought yogurt).

Step 11: Packaging & Distribution

Cooled yogurt is filled into individual containers (cups, bottles, or pouches) at high speed—up to 500 units per minute in modern facilities.

Containers are sealed, labeled with batch codes and expiration dates (typically 3-4 weeks from production).

Packaged yogurt is maintained at 4-5°C in refrigerated trucks and retail display cases until consumption.

Why This Process?

Precise temperature control is critical—both bacterial strains have narrow optimal temperature ranges, and deviations produce inferior texture or off-flavors.

Heat treatment denatures whey proteins, increasing their water-binding capacity and creating yogurt’s characteristic firm texture without added stabilizers.

Fermentation pH control prevents over-acidification that would separate the casein network and destroy the creamy mouthfeel.

What About Additives?

Most commercial yogurts include:

• Stabilizers (pectin, gelatin, xanthan gum) – to prevent whey separation

• Thickeners (cornstarch, modified tapioca starch) – for texture

• Added sugar or sweeteners – for taste

• Pectin – for fruit suspension

• Colorants (natural or synthetic) – for visual appeal

Plain, unsweetened yogurts may contain no additives beyond the cultures and milk.

Greek yogurt is made by straining regular yogurt to remove whey—this produces higher protein and thicker consistency without additives.

The Bottom Line

Yogurt production is a carefully controlled fermentation process that relies on two symbiotic bacterial strains, precise temperature management, and pH monitoring.

The process creates a living product—yogurt contains billions of viable probiotic bacteria that support digestive health.

Now you understand exactly how milk transforms into yogurt through microbial fermentation and why temperature control is the secret to perfect texture and probiotic potency.